(PA) Nylon Pipe Extrusion Line

(PA) Nylon Pipe Extrusion Line

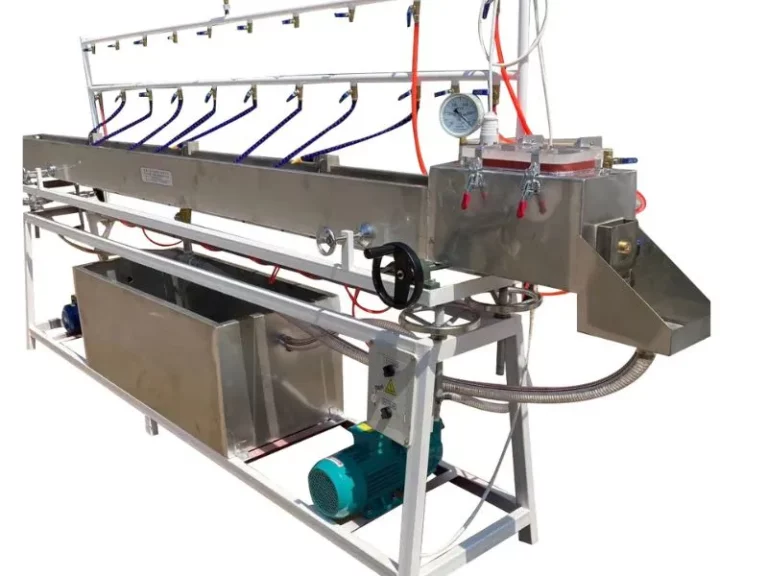

Adopting nylon special screw, solving the critical problem of complex material extrusion molding, good plasticizing effect, products without crystal point particles, air bubbles, continuous operation is stable, simple operation; unique in-line cutting device, making the product cut smooth and flat, no burr. Depending on the requirements of the products, it can also adopt double-station on-line automatic rewinding. Nylon tube is high temperature and corrosion-resistant and has been widely used in automobile brake fluid hose, fuel delivery hose, instrumentation line, air conditioning system, etc.

Technical Specifications

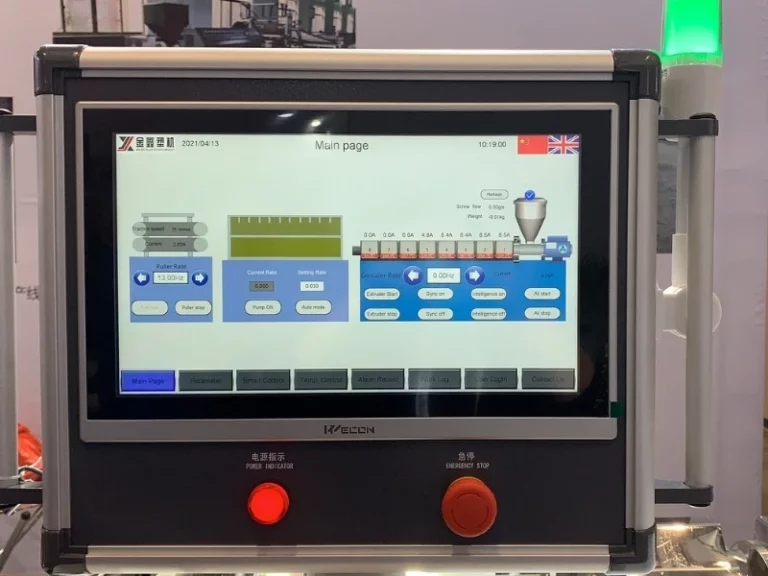

During the production of nylon pipes, temperature control for equipment differs from other plastic products. For instance, the feeding section of the extruder needs to be close to the resin’s melting point. In contrast, the plastification section requires a temperature around 20°C higher than the resin’s melting point. Then, in the homogenization section, the temperature decreases and is controlled just above the material’s melting point. Finally, the temperature needs to be slightly lower at the die head than in the homogenization section. (Taking the example of extrusion using PA1010 resin, the temperature control ranges for equipment sections, including feeding, plastification, homogenization, die-head connection, and mold, are: 250-260°C, 260-270°C, 260-280°C, 220-240°C, and 200-210°C, respectively.)

In pipe production, except for a few rigid pipes that may not require traction equipment, nylon pipe production necessitates traction equipment. The draw ratio of the traction equipment needs to be controlled between 1.2 and 1.5. Additionally, the water used for pipe cooling should be circulated and maintained between 15-22°C to ensure the quality of the final product.

Apart from the above considerations, it’s essential to note that polyamide resin melt is prone to decomposition, emphasizing the importance of temperature control without significant fluctuations. Whether using a horizontal or vertical entry into the cooling water tank during pipe forming, attention must be paid to the proximity of the die to the cooling water tank to ensure rapid cooling and setting of the pipe. When producing PA1010 nylon pipes, using materials with higher viscosity resin is advisable to prevent significant deformation when extruding material from the die opening.

nylon pipe samples

Our advantages / Q&A?

Most frequent questions and answers

Nylon tube classification is often divided into nylon 1010 hard tube, nylon 11 hose, nylon 12 hose, nylon 6 semi-hard tube, and nylon 66 hard tube. But there is a common point. Generally, the diameter of this tube is a small aperture, and the tube diameter range is controlled in φ20, so we recommend using smaller specifications of the single-screw extruder to extrude.

Polyamide resin has the ability to absorb air moisture, moisture and the production of nylon tube for the harmful elements, so the raw material must be dried before extrusion production, drying treatment of raw resin should be immediately put into production, while the charging hopper needs to be used to dry moisture-proof structure. General drying treatment is the raw material in the 80-90 ℃ temperature oven treatment 8-12 hours, or using boiling drying treatment for 1 hour, temperature control 110 ℃, the ultimate goal is to reduce the moisture content of the finished resin raw materials to 0.3% or less!

Translated with DeepL

Been specializing in single screw extruders for over 10 years.

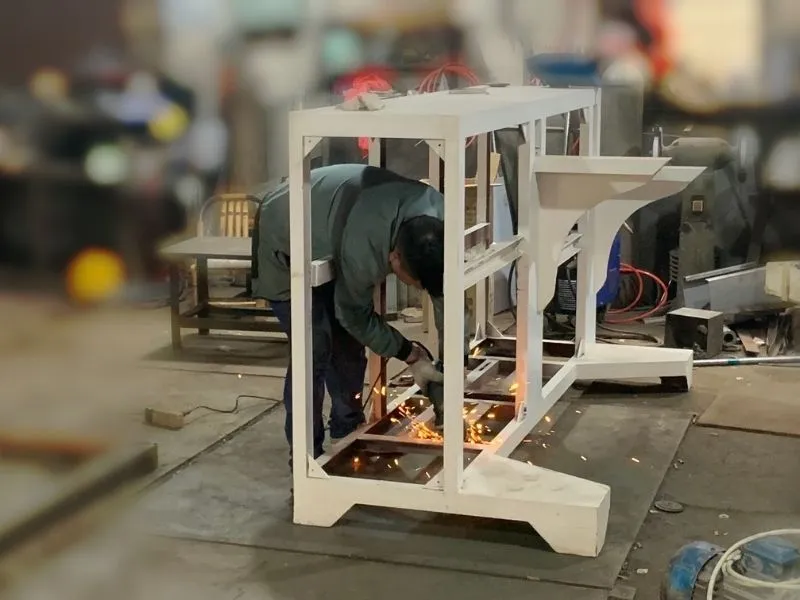

Jinxin Plastic Machinery is a china extruder machine manufacturer was founded in 2012. Our core business is manufacturing single-screw extrusion equipment, including the main extruder, water tank, hau-off, and cutting or collecting components. We have many years of experience in mold design and manufacturing, as well as partnering with other suppliers to offer customized equipment solutions to our customers.

Our mission is to provide the highest quality products and services to our customers, and we take that mission very seriously. We believe that our success is directly tied to the success of our customers, and we are committed to helping them achieve their goals by providing them with the best possible equipment and support.

When you're considering adding a new set of extrusion equipment to your factory

01

Tell us the basics about your product

Please provide information about the raw material and size of the product you wish to produce. Having pictures or drawings to provide is the most intuitive. In addition, some requirements about the way the final product is collected and logo printing etc. need to be provided as well

02

discuss your project with us

We customize your equipment based on your product requirements, always taking the most professional approach. While some new clients may wonder why we don't follow their equipment specifications, it's because our expertise is built on years of experience.

03

complete the machine production

Once the equipment is completed, we ensure that each production line undergoes a thorough factory test before shipment. Additionally, we offer on-site installation of the equipment and provide training to the customer's staff on its usage.

04

Prompt after-sales service

We will have specialized export business personnel to interface with you. Provide timely and effective after-sales service. Warranty policy as well as adequate spare parts for wear and tear are provided

We are honest and reliable, providing cost-effective equipment for your factory

Our Customers Say

Our amazing Suppliers

Get A Quote

we will answer your inquiry within 24hrs via Emails with the suffix jfextruder.com.

We are always ready for all your needs.

If you have specific plastic product requirements in mind or questions about adding new equipment, don’t hesitate to reach out to us. Your needs and inquiries are our top priority. Contact us today to discuss how we can tailor our solutions to meet your unique goals

Factory

No. 31 Yuci Rd., Yuyao, Ningbo City, Zhejiang Province, China