LED Linear Lighting Profile Extrusion Line

LED Linear Lighting Profile Extrusion Line

Applications :

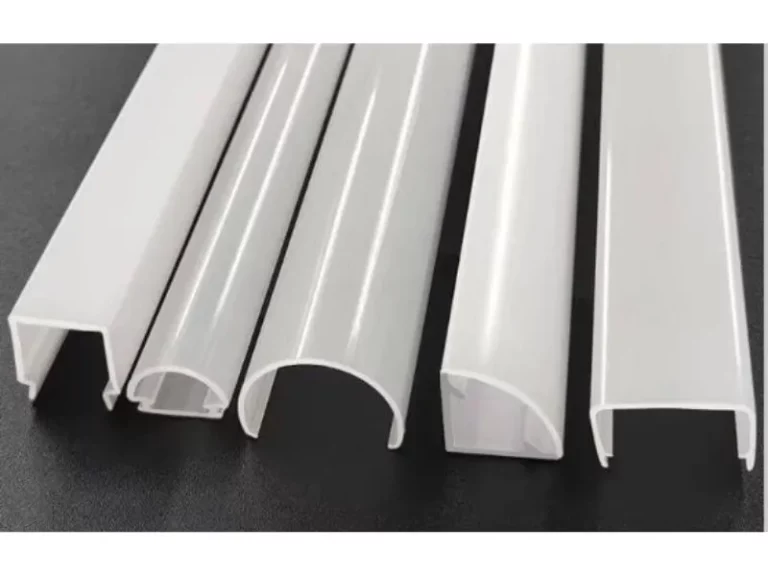

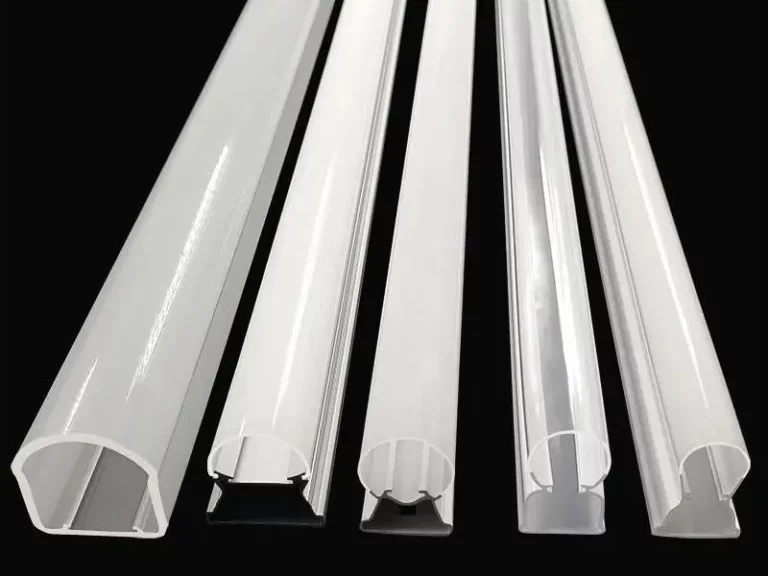

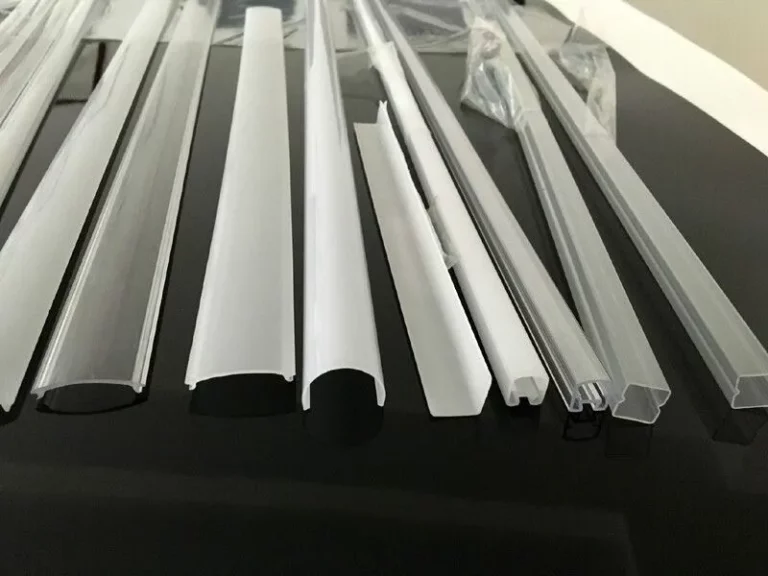

LED lighting extrusion is one of the housing parts of linear LED lamps. They come in various configurations and sizes, such as flat, tubular, semi-circular, and irregular. Some have beam angles, often called optical lenses, and some do not. The colors are transparent, translucent, and milky white. Depending on the application, some are rigid, and some are flexible. They are mounted on LEDs to produce the desired lighting effect. The various properties of LED extruded lenses allow for precise control of the light beam.LED plastic extrusion profiles also provide an aesthetic appearance by hiding the LED components inside.

- LED Linear Lighting Tube

- LED Lighting Lampshade

- LED Lighting Housings

- Linear Light Diffuser

Customization Options:

Including glossy, two-color co-extruded, frosted, sandblasted, wide diffusion, semi-circular, and so on.

PC/PMMA Lighting Profile Extrusion Line

The lighting industry has always relied on glass and clear plastics such as PMMA (acrylic, plexiglass) for optical designs that are functional and aesthetically pleasing. However, with the advent of LED lighting technology, the need for a higher degree of light diffusion has required the development of suitable plastic solutions to do the job better.

There are a variety of plastic materials such as PC, PMMA and PS that are widely used in the LED lighting industry. Generally speaking, both PMMA and PC materials can replace glass and are odorless, non-toxic, antimicrobial, and 100% recyclable. However, they have different characteristics.

Technical Specifications

Extruded hosts are our most mature products. The unique screw and barrel for the PC material of the extruder are made of high-strength nitrided alloy steel (38CrMoALA) or high-strength quenched alloy steel (9Cr18MoV). We have especially designed the Gravimetric Dosing Controller system for rigid profiles; see our knowledge article:

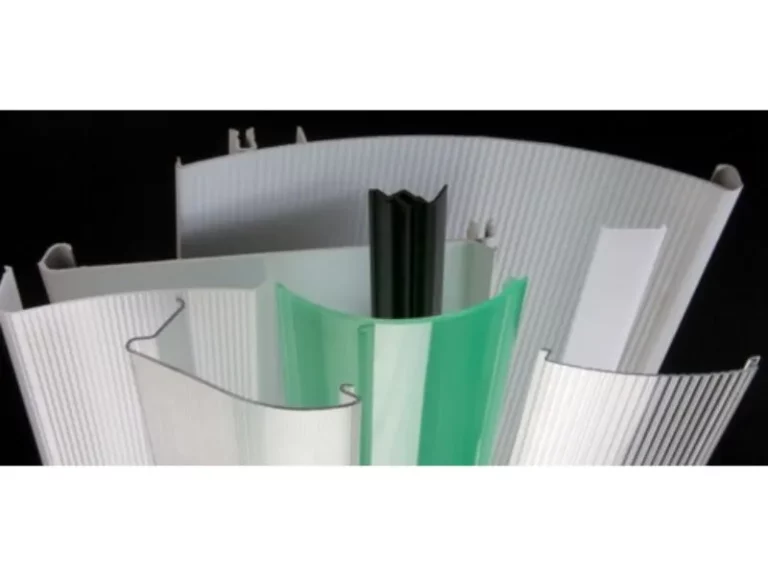

Co-extrusion is a process required for the production of two-color lamps, lampshades, etc. Our co-extrusion equipment can be controlled by PLC system together with the host machine and haul-off to achieve precise extrusion production results.

The subsequent production steps are hauling and cutting. We can laminate the surface of the product after the production of PC lamps and lanterns according to the customer’s demand, in order to protect the PC lamps and lanterns from wear and tear.

Post-production samples

Our Advantages

Most frequent questions and answers

The mold is made of S-136H mirror steel, and the surface of the mold is polished to mirror, which makes the product without pulling marks, vibration pattern, and high transparency.

Fully automatic saw blade cutting machine, using computer board control, encoder fixed length, imported saw blade cutting, with a 2-meter flap frame, pneumatic flap, cutting machine accuracy ±1mm, Cutting machine accuracy ±1mm.

One of our customers produces lampshades supplied to high-speed trains in China. All product indexes are top-level in the industry.

Been specializing in single screw extruders for over 10 years.

Jinxin Plastic Machinery is a china extruder machine manufacturer was founded in 2012. Our core business is manufacturing single-screw extrusion equipment, including the main extruder, water tank, hau-off, and cutting or collecting components. We have many years of experience in mold design and manufacturing, as well as partnering with other suppliers to offer customized equipment solutions to our customers.

Our mission is to provide the highest quality products and services to our customers, and we take that mission very seriously. We believe that our success is directly tied to the success of our customers, and we are committed to helping them achieve their goals by providing them with the best possible equipment and support.

When you're considering adding a new set of extrusion equipment to your factory

01

Tell us the basics about your product

Please provide information about the raw material and size of the product you wish to produce. Having pictures or drawings to provide is the most intuitive. In addition, some requirements about the way the final product is collected and logo printing etc. need to be provided as well

02

discuss your project with us

We customize your equipment based on your product requirements, always taking the most professional approach. While some new clients may wonder why we don't follow their equipment specifications, it's because our expertise is built on years of experience.

03

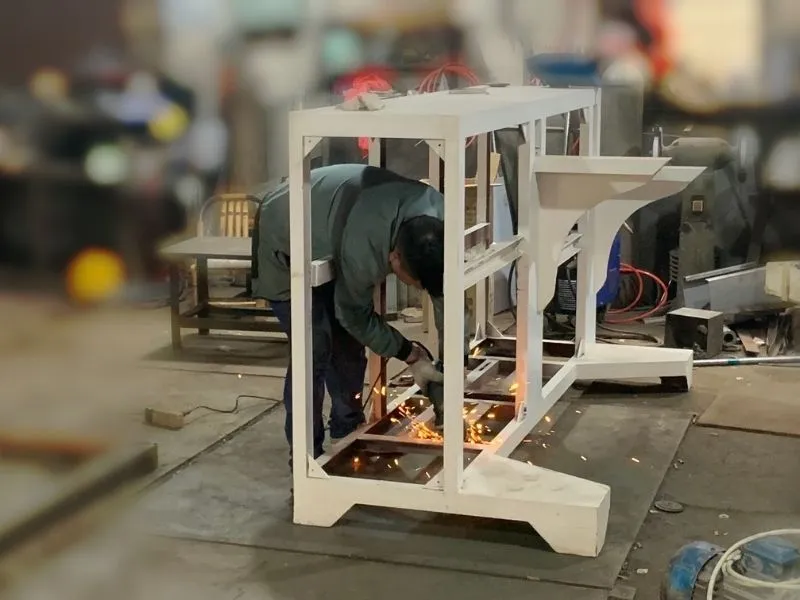

complete the machine production

Once the equipment is completed, we ensure that each production line undergoes a thorough factory test before shipment. Additionally, we offer on-site installation of the equipment and provide training to the customer's staff on its usage.

04

Prompt after-sales service

We will have specialized export business personnel to interface with you. Provide timely and effective after-sales service. Warranty policy as well as adequate spare parts for wear and tear are provided

We are honest and reliable, providing cost-effective equipment for your factory

Our Customers Say

Our amazing Suppliers

Get A Quote

we will answer your inquiry within 24hrs via Emails with the suffix jfextruder.com.

We are always ready for all your needs.

If you have specific plastic product requirements in mind or questions about adding new equipment, don’t hesitate to reach out to us. Your needs and inquiries are our top priority. Contact us today to discuss how we can tailor our solutions to meet your unique goals

Factory

No. 31 Yuci Rd., Yuyao, Ningbo City, Zhejiang Province, China