Marker Nibs Production Line

Overview of Marker Nibs Production Line

JINXIN and Porex Group Malaysia factory developed and manufactured this production line in the USA.

JINXIN previously only supplied machines for hauling and cutting. The Porex Group Malaysia factory designs the other parts. After that, according to the demand of other customers, we started to create a whole set of equipment. The different shapes of the nibs require additional grinding machines to grind the produced nibs into the customers’ required conditions, one grinding machine for each condition.

Technical Specifications

The entire production of nibs requires less extrusion equipment than many people think. This is unnecessary, as the fiber is supplied directly from the supplier to produce the nibs.

Shelves for the fiber wires

Confidentiality clauses prevent us from placing pictures of equipment on our customers’ premises. This is an alternative product image for approximate demonstration. This is a shelf to hold the fiber thread drums. Multiple strands of fiber are stretched into a single strand in a merger machine, then run through a pencil-forming machine where they are heat bonded to a specific adhesive, and then an oven is used to evaporate the solvents from the glue.

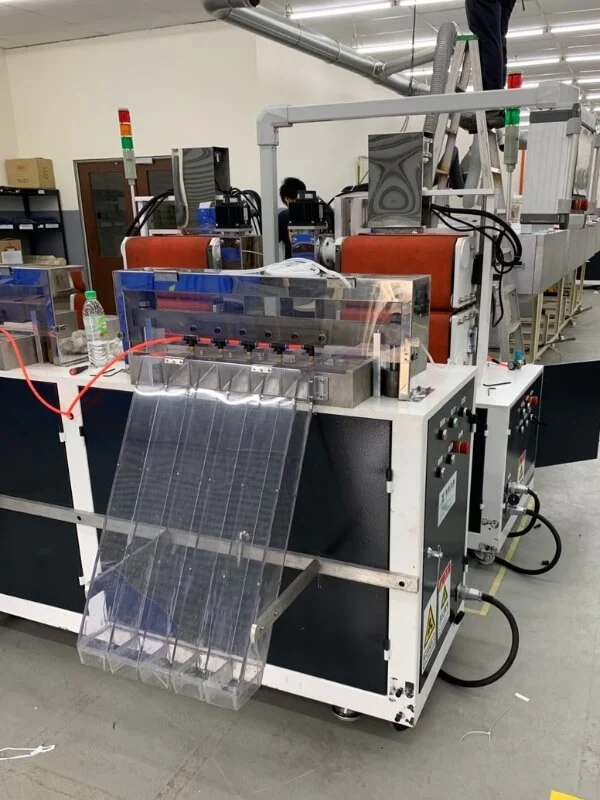

Maker Nibs Haul Off Machine and Cutter

Haul the fiber nibs dried in the previous sequence to the cutter. Finally, the foamed fiber nibs are cut to length, surface abraded and dried to get the finished nibs. Then, according to the shape of the customer’s nibs, we will grind them into the required shape.

Post-production samples

Been specializing in single screw extruders for over 10 years.

Jinxin Plastic Machinery is a china extruder machine manufacturer was founded in 2012. Our core business is manufacturing single-screw extrusion equipment, including the main extruder, water tank, hau-off, and cutting or collecting components. We have many years of experience in mold design and manufacturing, as well as partnering with other suppliers to offer customized equipment solutions to our customers.

Our mission is to provide the highest quality products and services to our customers, and we take that mission very seriously. We believe that our success is directly tied to the success of our customers, and we are committed to helping them achieve their goals by providing them with the best possible equipment and support.

When you're considering adding a new set of extrusion equipment to your factory

01

Tell us the basics about your product

Please provide information about the raw material and size of the product you wish to produce. Having pictures or drawings to provide is the most intuitive. In addition, some requirements about the way the final product is collected and logo printing etc. need to be provided as well

02

discuss your project with us

We customize your equipment based on your product requirements, always taking the most professional approach. While some new clients may wonder why we don't follow their equipment specifications, it's because our expertise is built on years of experience.

03

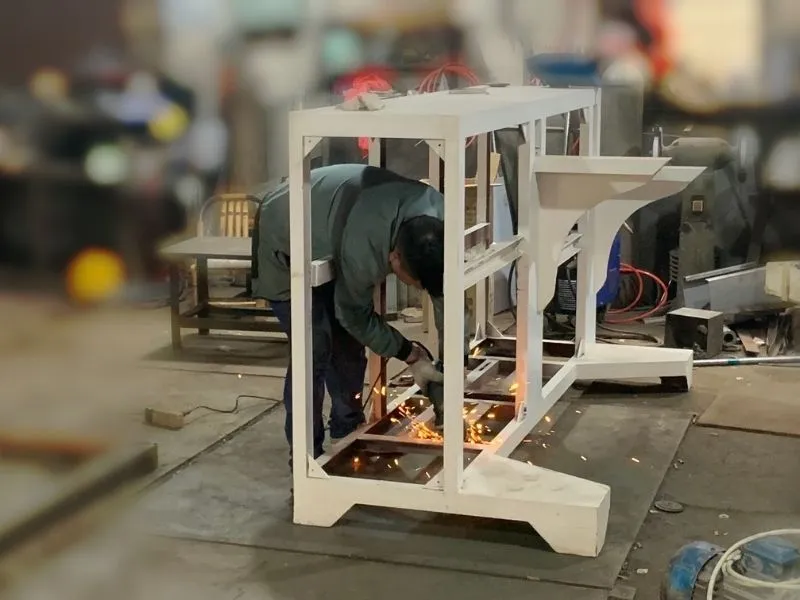

complete the machine production

Once the equipment is completed, we ensure that each production line undergoes a thorough factory test before shipment. Additionally, we offer on-site installation of the equipment and provide training to the customer's staff on its usage.

04

Prompt after-sales service

We will have specialized export business personnel to interface with you. Provide timely and effective after-sales service. Warranty policy as well as adequate spare parts for wear and tear are provided

FAQ

Most frequent questions and answers

Yes, we will provide you with various details about the required fiber. It is relatively easy to procure directly; however, special production arrangements need to be made through chemical fiber companies.

Besides the equipment we offer, preparing a protective enclosure in the oven section is essential due to the unique smell of the adhesive used for synthetic fibers. We will provide recommendations and guidance on this.

We are honest and reliable, providing cost-effective equipment for your factory

Our Customers Say

Our amazing Suppliers

Get A Quote

we will answer your inquiry within 24hrs via Emails with the suffix jfextruder.com.

We are always ready for all your needs.

If you have specific plastic product requirements in mind or questions about adding new equipment, don’t hesitate to reach out to us. Your needs and inquiries are our top priority. Contact us today to discuss how we can tailor our solutions to meet your unique goals

Factory

No. 31 Yuci Rd., Yuyao, Ningbo City, Zhejiang Province, China