Laboratory Plastic Pipette Production Line

Laboratory Plastic Pipette Production Line

Applications :

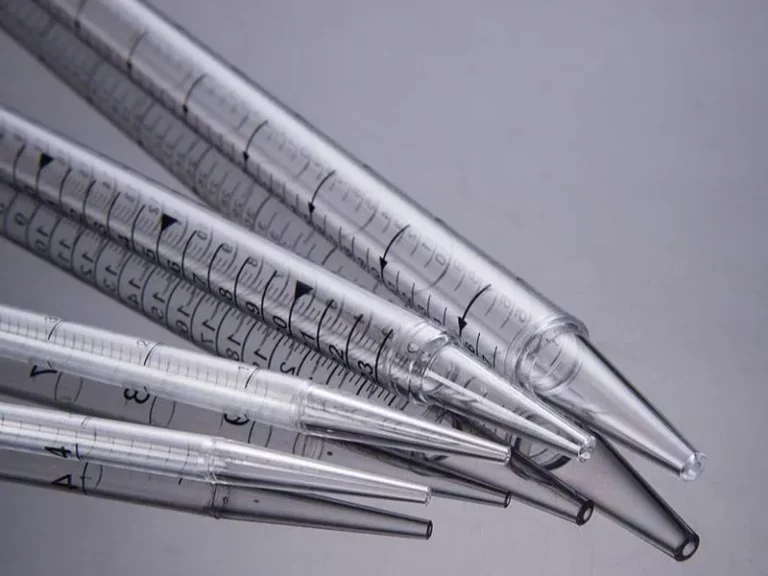

This production line is specifically designed to manufacture plastic pipettes, essential laboratory tools for biological research, tissue culture, and cell cultivation. Crafted from high-transparent polystyrene, these pipettes facilitate precise measurements and experiments.

- No pyrogen, cytotoxicity or hemolysis

- Polyolefin filter element to prevent pollution

- No DNase, no RNase.

Customization Options:

We offer customizable automation solutions tailored to our clients’ specifications regarding product dimensions and production volumes.

Our production line is versatile and capable of producing all seven standard sizes of pipettes circulating in the market: 1ml, 2ml, 5ml, 10ml, 25ml, 50ml, and 100ml.

Whatever your requirements, our equipment is designed to meet them, ensuring precision and efficiency in every pipette produced.

Pipette Production Line Overview

The comprehensive equipment includes extrusion molding units, ultrasonic welding devices, leak testing mechanisms, cotton plug insertion devices, silk-screen printing, and packaging units. Perfect for maintaining accuracy and quality in scientific applications. The end of the tube is marked with a color ring, and the body has a corresponding color bar background, which is convenient for quickly identifying the capacity: positive and negative double-scale design, clear printing, and improved sampling accuracy.

Technical Specifications

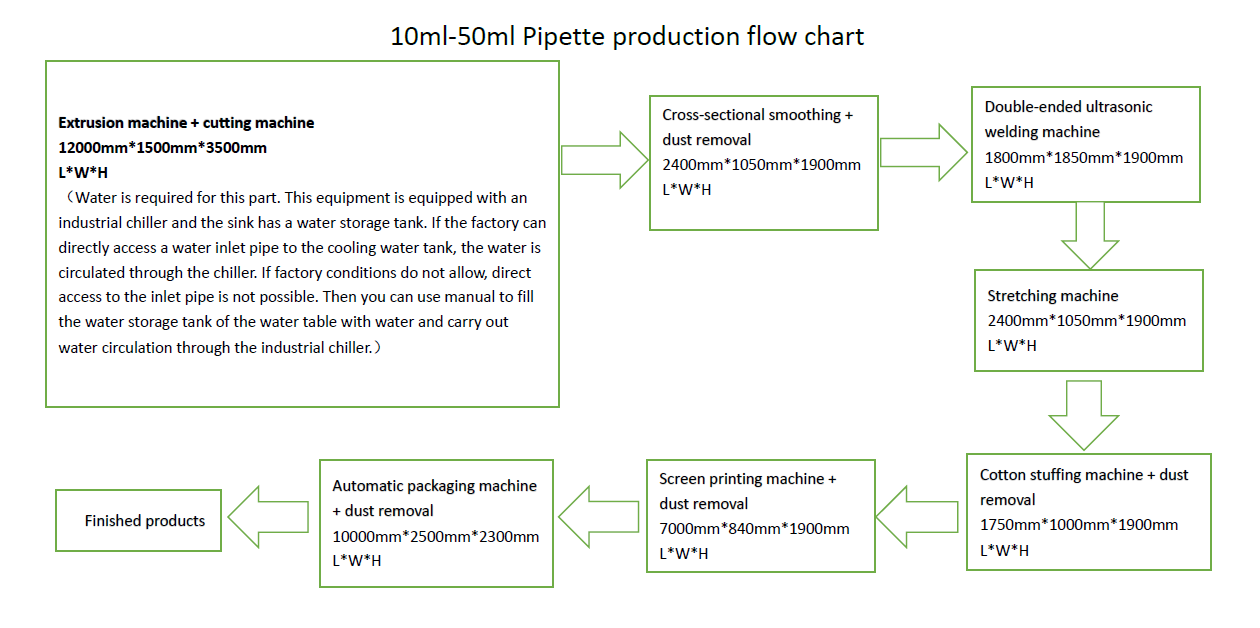

Specific equipment and process flow required for a complete pipette production line

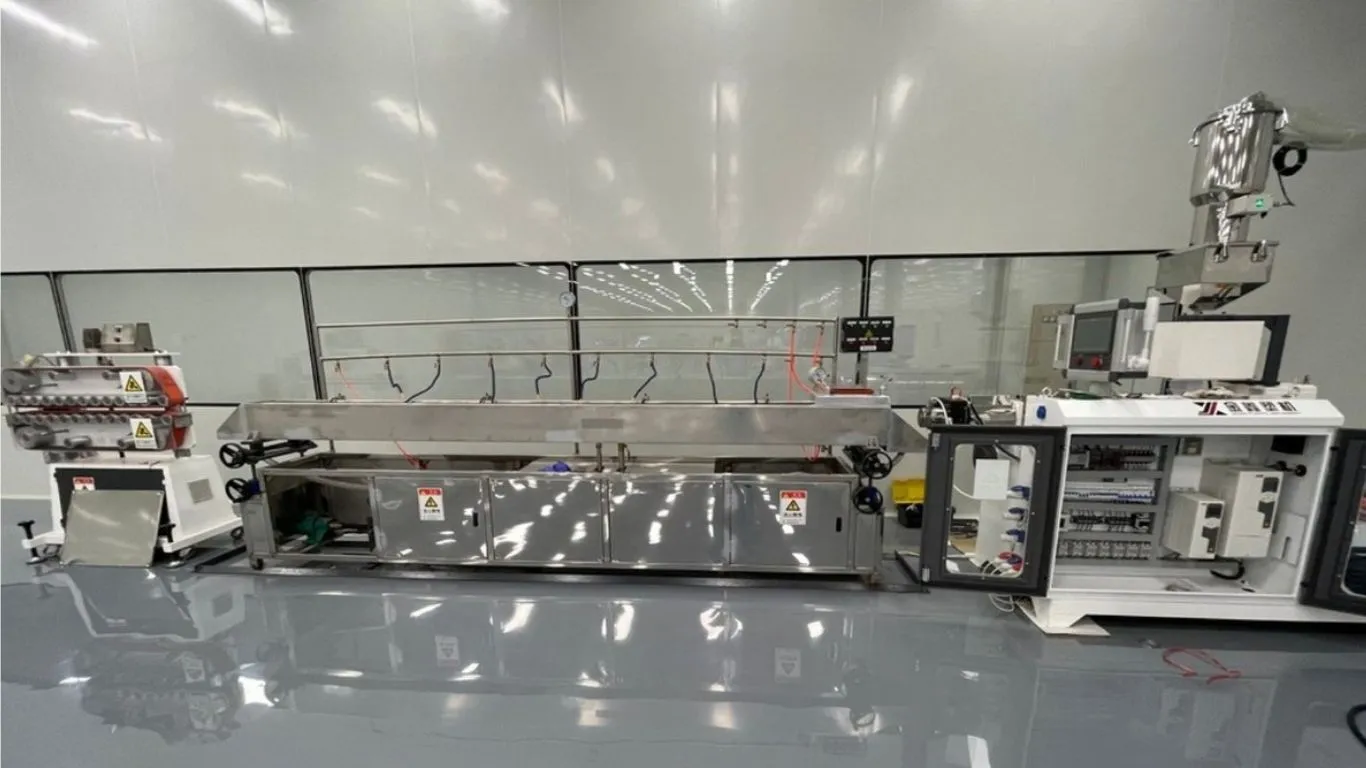

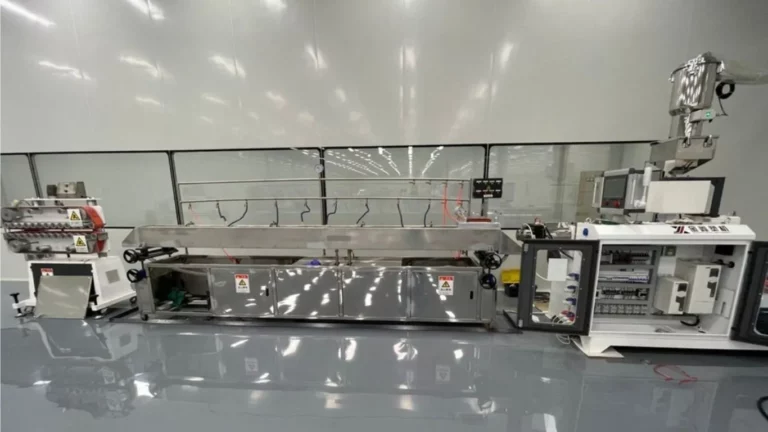

Tube Body Extrusion Equipment

The extrusion equipment is still a single screw and water-cooled table, haul-off, and cutting machine. The kit can be aseptically stainless steelized according to the customer’s needs for aseptic production. A wide range of customers recognizes the precision and transparency of our extrusions.

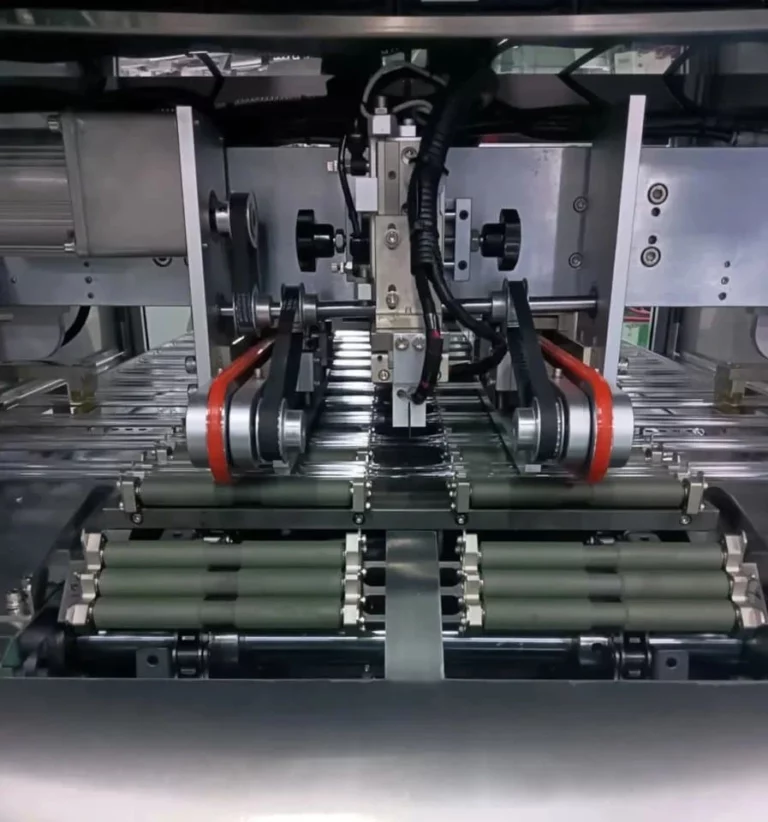

Ultrasonic welding or stretching of tube heads

Depending on the pipe size, there are two production processes: ultrasonic welding and stretching. Multiple stations are available according to production requirements. The next step is to stuff the cotton core into the tube body, customized according to the customer’s needs. Some tubes are used for blood sedimentation tests and do not require a cotton wick.

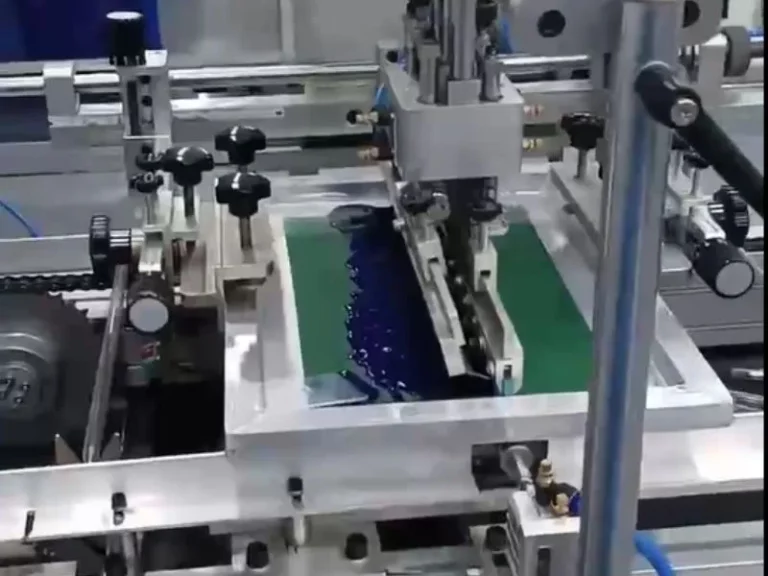

Tube Body Printing

Screen printing is used to print different scales and labels etc. on the tube body.

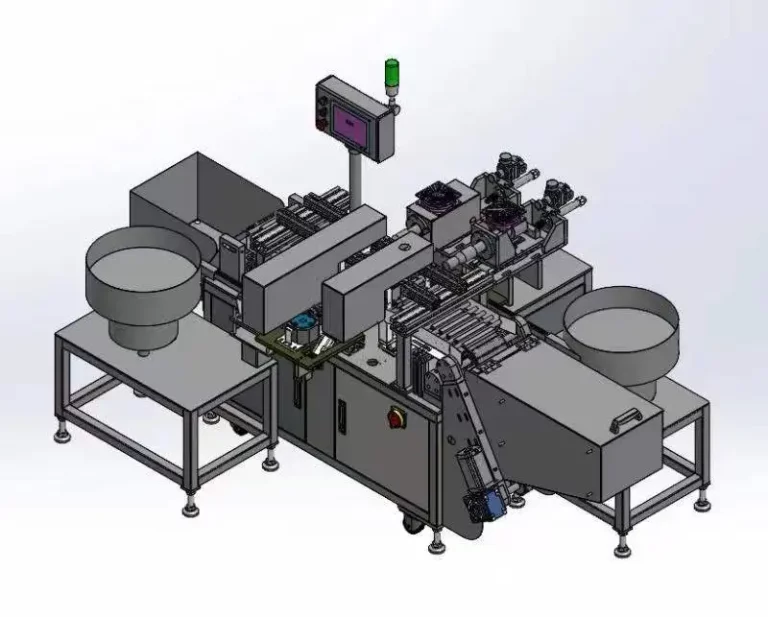

Packaging

The automatic packaging machine packs the tubes individually in paper-plastic bags. To achieve the requirements of sterility and dustlessness, etc.

Post-production samples

FAQ

Most frequent questions and answers

Yes, indeed. You require a plastic injection machine using the injection molding process to create the nozzles necessary for pipette production. While we don’t manufacture these, we can recommend suitable options to our customers.

First and foremost, our expertise lies in extrusion equipment. The pipettes produced using our extrusion machines boast high transparency, making them ideal substitutes for glass test tubes. Additionally, our pipettes have precise volume capacities. One of our clients, who previously used an Italian brand extrusion machine, switched to our production equipment due to the superior transparency of the pipettes. Our second strength lies in our extensive experience with customized post-production equipment. Based on customer feedback, we’ve identified high-quality suppliers and actively participate in the equipment’s setup and calibration process.

Our amazing Suppliers

Been specializing in single screw extruders for over 10 years.

Jinxin Plastic Machinery is a china extruder machine manufacturer was founded in 2012. Our core business is manufacturing single-screw extrusion equipment, including the main extruder, water tank, hau-off, and cutting or collecting components. We have many years of experience in mold design and manufacturing, as well as partnering with other suppliers to offer customized equipment solutions to our customers.

Our mission is to provide the highest quality products and services to our customers, and we take that mission very seriously. We believe that our success is directly tied to the success of our customers, and we are committed to helping them achieve their goals by providing them with the best possible equipment and support.

When you're considering adding a new set of extrusion equipment to your factory

01

Tell us the basics about your product

Please provide information about the raw material and size of the product you wish to produce. Having pictures or drawings to provide is the most intuitive. In addition, some requirements about the way the final product is collected and logo printing etc. need to be provided as well

02

discuss your project with us

We customize your equipment based on your product requirements, always taking the most professional approach. While some new clients may wonder why we don't follow their equipment specifications, it's because our expertise is built on years of experience.

03

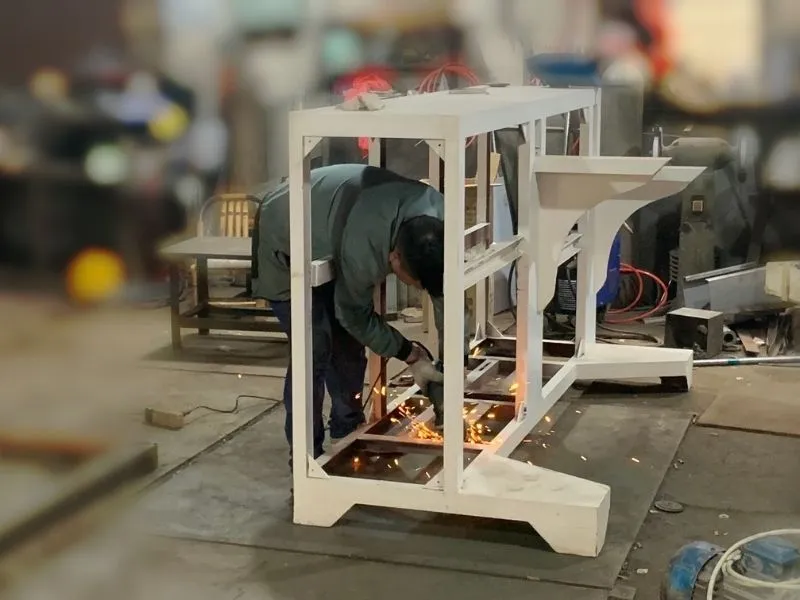

complete the machine production

Once the equipment is completed, we ensure that each production line undergoes a thorough factory test before shipment. Additionally, we offer on-site installation of the equipment and provide training to the customer's staff on its usage.

04

Prompt after-sales service

We will have specialized export business personnel to interface with you. Provide timely and effective after-sales service. Warranty policy as well as adequate spare parts for wear and tear are provided

We are honest and reliable, providing cost-effective equipment for your factory

Our Customers Say

Our amazing Suppliers

Get A Quote

we will answer your inquiry within 24hrs via Emails with the suffix jfextruder.com.

We are always ready for all your needs.

If you have specific plastic product requirements in mind or questions about adding new equipment, don’t hesitate to reach out to us. Your needs and inquiries are our top priority. Contact us today to discuss how we can tailor our solutions to meet your unique goals

Factory

No. 31 Yuci Rd., Yuyao, Ningbo City, Zhejiang Province, China