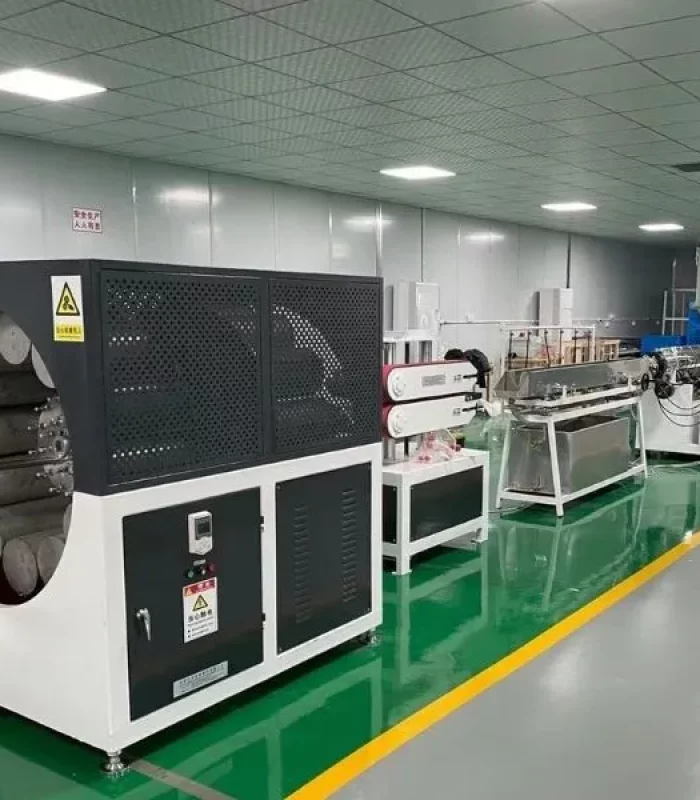

Comprehensive Single Screw Extruder Applications For Diverse Manufacturing Needs

Single Screw Extruder Applications

Our advanced extrusion equipment is designed to cater to a variety of applications, enabling the production of high-quality pipes, hoses, tubes, and profiles. By categorizing our machinery based on application, we provide an intuitive and efficient way for customers to find the exact equipment they need for their specific production requirements.

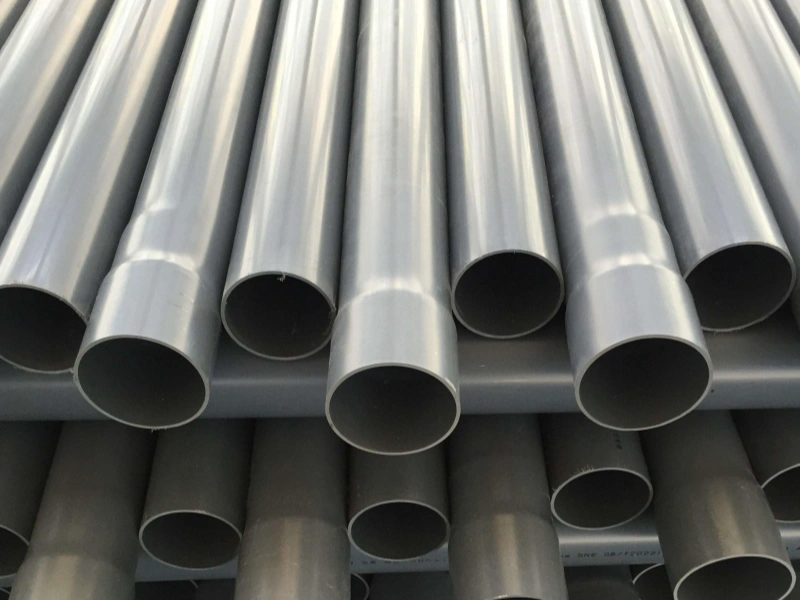

Pipe

OD:20-315mm

Water supply, electricity, natural gas, chemical industry, agriculture, fishery, construction, sewers and other projects.

Single screw extruders and only PVC pellets can be used. For more information, please contact us!

OD:20-315mm

Water supply pipes and drainage pipes, and sometimes used in the transportation of other chemicals.

OD:20-160mm

Water transportation pipes, including drinking water, cold water and hot water, central air conditioning systems, etc.

Glass fiber reinforced pipe production line is also available

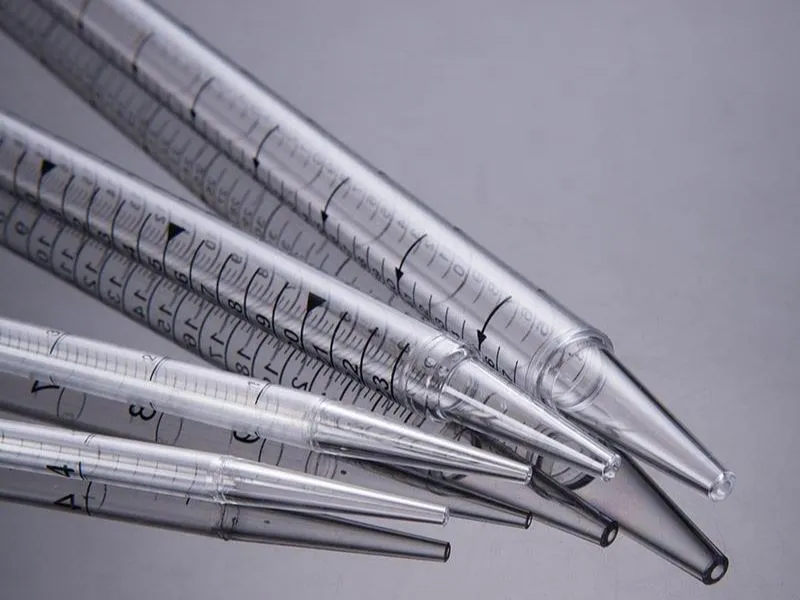

Volume: 1ml,2ml,5ml,10ml,25ml,50ml,100ml

Plastic pipettes, essential laboratory tools for biological research, tissue culture, and cell cultivation.

Crafted from high-transparent polystyrene, these pipettes facilitate precise measurements and experiments.

Hose

PVC reinforced hoses are constructed with multiple layers of PVC, with a fiber braided layer in between to enhance pressure resistance.

These hoses are commonly used for applications such as washing machine water inlet hoses and garden watering hoses, providing durability and flexibility for household and gardening needs.

Similar in structure to the reinforced hoses, these PVC shower hoses feature a smooth, multi-colored outer layer, typically silver.

They are popular for use in modern showers due to their aesthetic appeal and durable construction.

These hoses have a sleek, bright silver matte finish, achieved through heat transfer technology.

They are often used by high-end brands to produce luxury shower hoses that not only look premium but also offer excellent durability and flexibility.

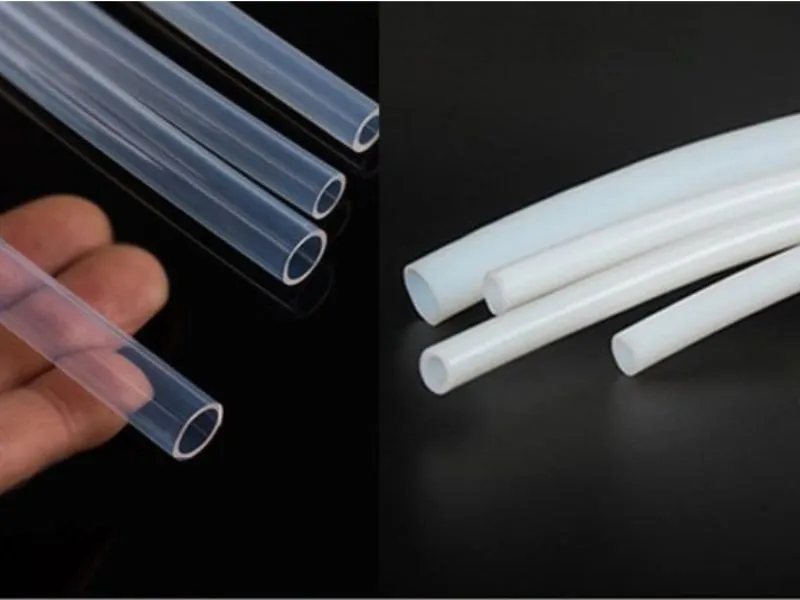

Tube

PVC soft tubing is highly flexible and durable, making it ideal for applications requiring easy handling and long-lasting performance.

Common uses include medical tubing, and food and beverage transfer systems, where flexibility and resistance to wear are critical.

PA12 and PA66 tubing is specifically designed for automotive applications, where high resistance to heat and chemicals is essential.

These tubes are used in fuel lines, brake systems, and other critical automotive components, ensuring safety and durability under extreme conditions.

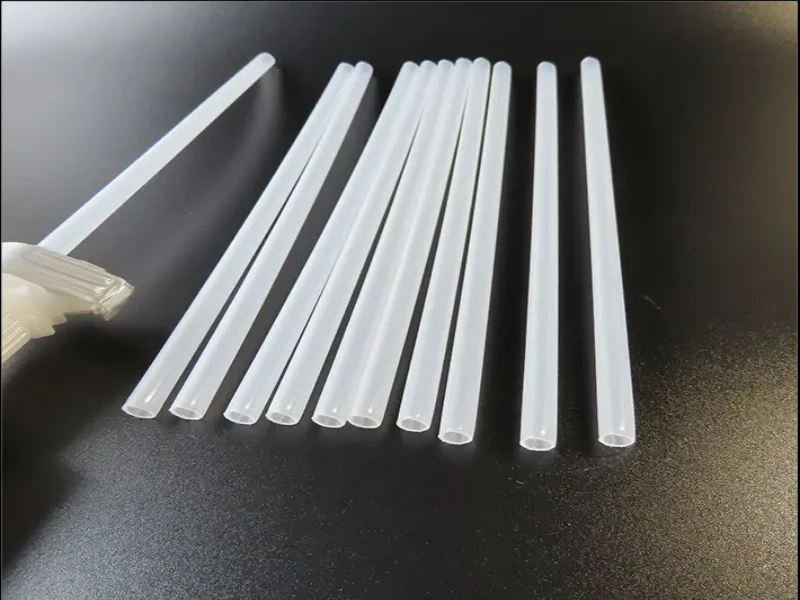

PP (Polypropylene) and PE (Polyethylene) dip tubes are commonly found in cosmetic and household product packaging.

These dip tubes are used in pump bottles for products like shampoos, lotions, and sprays, providing an efficient means for dispensing liquids from containers.

TPU (Thermoplastic Polyurethane) soft tubing offers excellent elasticity, transparency, and abrasion resistance.

It is widely used in applications such as pneumatic lines, fuel lines, and hydraulic systems, providing reliable performance in demanding environments.

Profile

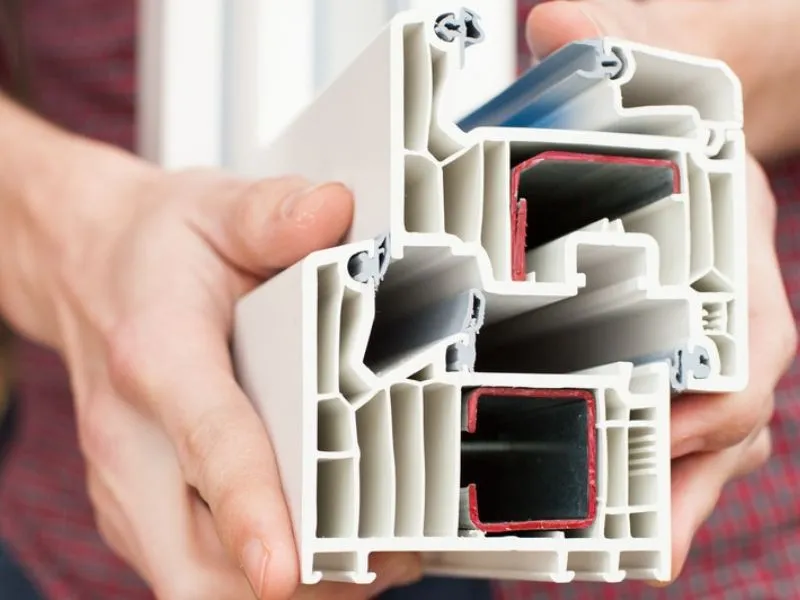

PVC profiles are widely used for doors and windows due to their excellent weather resistance and durability.

These profiles maintain their appearance and performance over time, even in harsh environmental conditions, making them a reliable choice for both residential and commercial buildings.

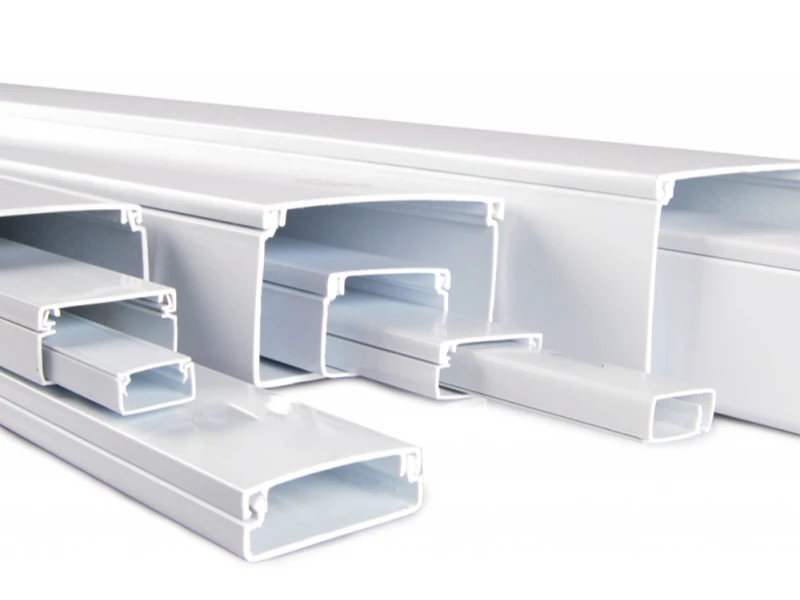

PVC trunking is commonly used to organize power cables, data cables, and other wires, preventing leakage and ensuring a neat and safe environment.

It is an essential component in both residential and commercial settings, providing a clean and efficient way to manage wiring.

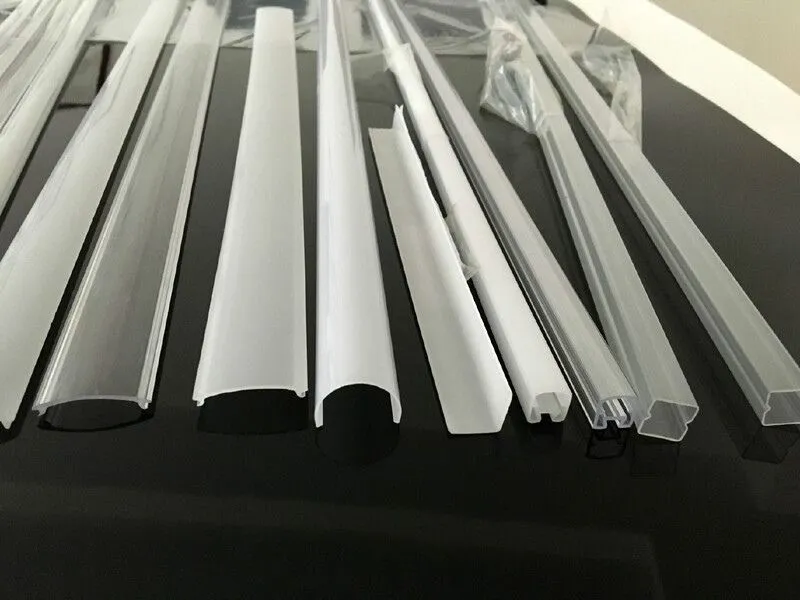

Profiles made from PC (Polycarbonate) and PMMA (Acrylic) are used in LED lighting applications, including diffusers and tubes.

These profiles can have various finishes such as transparent, textured, diffusing, frosted, colored, or satin, enhancing both the functionality and aesthetic appeal of LED lighting fixtures.

Bandage

Thermoplastic Elastomers (TPE) as raw material.It is a class of copolymers or a physical mix of polymers (usually a plastic and a rubber).

It consist of materials with both thermoplastic and elastomeric properties. Eco-friendly and Latex-free materials

Thermoplastic Elastomers (TPE) as raw material. It is a class of copolymers or a physical mix of polymers (usually a plastic and a rubber).

It consist of materials with both thermoplastic and elastomeric properties. Eco-friendly and Latex-free materials

Thermoplastic Elastomers (TPE) as raw material. It is a class of copolymers or a physical mix of polymers (usually a plastic and a rubber).

It consist of materials with both thermoplastic and elastomeric properties. Eco-friendly and Latex-free materials

Pain Points and Solutions Before Making Purchasing Decision

As a potential buyer from another country looking to invest in high-value extrusion equipment, we understand the challenges and uncertainties you might face. Here, we address common concerns to help you feel more confident about your decision.

High Investment, No Physical Samples

Extrusion equipment is a significant investment, and without physical samples, it can be hard to trust online information.

Solutions

We provide detailed videos showcasing our equipment in operation, along with customer testimonials and case studies. This gives you a clear view of the machine's performance and reliability.

Lack of On-Site Demonstrations

Our equipment is highly customized, and it's challenging to see a fully operational machine in our factory due to the specific nature of each order.

Solutions

If you visit China, we can arrange for you to see our machines in action at our customer's factories, provided the purchasing process is nearing completion.

Trust and Credibility Issues

Trusting an overseas supplier for such a large purchase can be daunting, especially when you can't physically inspect the machinery.

Solutions

You can witness the test runs of your specific equipment at our factory before shipping. Alternatively, we can provide detailed video documentation of the test runs. We can also connect you with existing clients in your country for direct feedback.

Why Choose Our Extrusion Machine

Expertise you can trust

When selecting equipment for your new project, it’s crucial to address the key pain points of quality, cost efficiency, reliability, and trusted expertise. Here’s why our equipment stands out as the best choice to meet these needs:

Proven Quality

Over a decade of experience and customer feedback ensures our selected machines offer long-term durability and reliable performance.

Exceptional Value

We provide high-quality equipment at competitive prices, maximizing your investment with top-tier performance.

Reliable Support

Comprehensive support and service ensure smooth operation and minimal downtime, maintaining optimal productivity.

About JINXIN Plastic Machinery

Since 2012

We are honest and reliable, providing cost-effective equipment for your factory

By choosing our equipment, you are partnering with a supplier dedicated to resolving your pain points with expertly curated, high-quality, and cost-effective solutions. We stand by the reliability and performance of every product we offer, ensuring that your investment delivers the results you need for your business to thrive.

Our Customers Say

Our amazing Suppliers

EXTRUSION SOLUTIONS

Let's get in touch

Email Address

Factory Address

No. 31 Yuci Rd., Yuyao, Ningbo City, Zhejiang Province, China