High-Precision PC Profile Extrusion Line

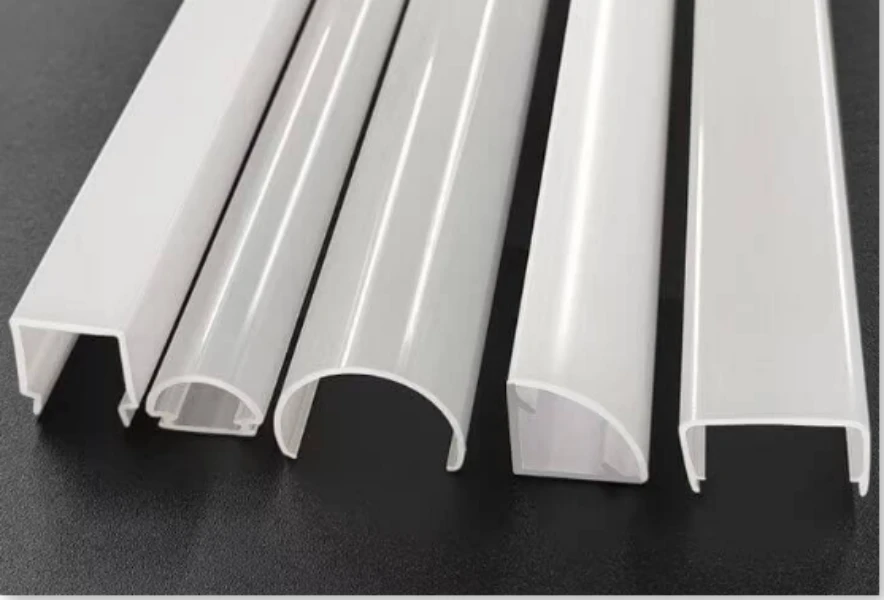

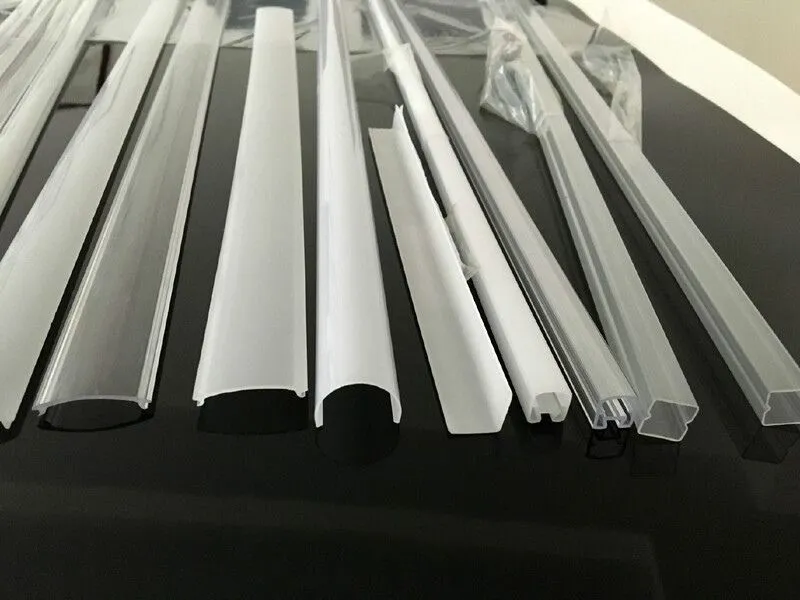

PC PMMA LED cover profile extrusion line designed for optical-grade clarity, superior dimensional stability, and scratch-free production.

Engineered for Excellence: Core Components of the PC Profile Extrusion Line

To achieve optical-grade clarity and superior structural integrity, every module in the Jinxin PC Profile Extrusion Line is built with premium alloys and world-class electronics.

Our integrated system ensures seamless synchronization between high-torque melting, precision vacuum calibration, and automated surface protection, delivering a high-uptime solution for demanding LED and industrial applications.

High-Torque Main Extruder

- Drive System: ABB frequency inverter coupled with a 6-pole motor and Type 173 hardened-surface gearbox.

- Control Interface: 15-inch PLC touchscreen and synchronized speed adjustment for extruder and haul-off.

- Thermal Regulation: Dedicated heating modules controlled by Taiwan FOTEK solid-state relays (SSR) with scheduled pre-heating and fault diagnostic display.

- Plasticization: Nitrided alloy screw and barrel specifically profiled for PC/PMMA resin stability.

Mobile Co-Extruder (For Dual-Color/Frosted)

- Positioning: Electric height adjustment (900-1200mm range) with a 270° rotating cantilever control box for multi-angle integration.

- Drive System: ABB frequency inverter with Type 146 hardened-surface gearbox and direct-coupled motor.

- Data Management: Independent PLC control with process parameter archiving and remote monitoring capabilities.

Inverter-Controlled Vacuum Calibration Table

- Pressure Control: Vacuum pump regulated by an ABB frequency inverter, adjustable via the main HMI or manual override.

- Cooling Infrastructure: 10-channel manifold for vacuum, 10-channel for water, and 10-channel for air-blow, integrated into a stainless steel cooling tank.

- Profile Support: Anti-sagging support frames for wide-profile extrusion to maintain cross-sectional geometry.

- Alignment: Motorized forward/backward movement with manual 3-axis (X/Y/Z) adjustment.

Automatic Saw Cutting Machine

- Length Control: Encoder-based measurement with computer-board control for repeatable sizing.

- Cutting Accuracy: Precision tolerance of ±1mm.

- Edge Quality: Imported saw blades for burr-free cutting of rigid PC/PMMA profiles.

- Collection: Pneumatic tilting stacker for organized product discharge.

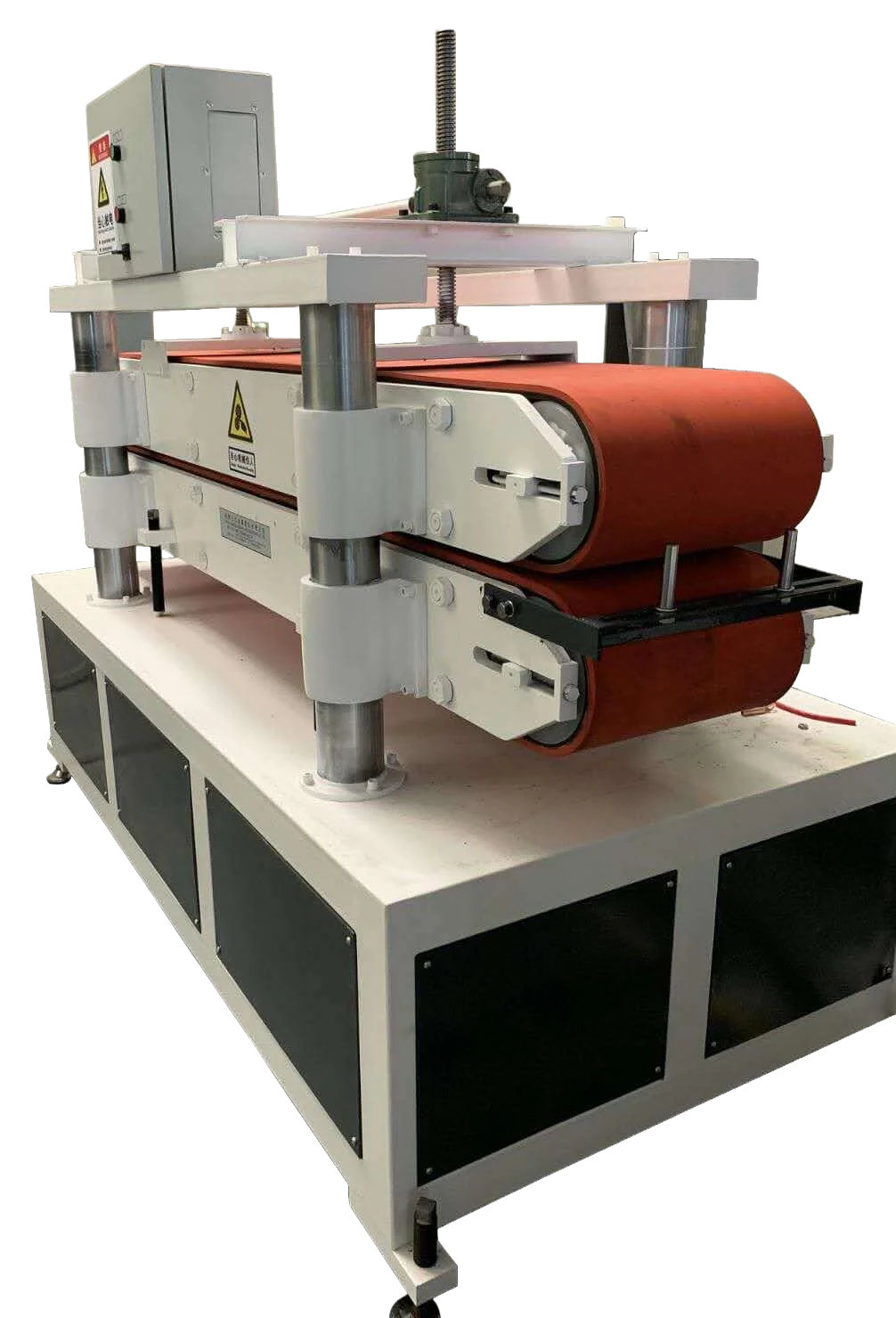

Post-Cutting Film Applicator

- Function: Automatic protective film application unit positioned after the cutting process.

- Purpose: Applies PE protective tape to the finished profile to prevent surface scratches during collection, packaging, and transport.

Ready to Configure Your PC Profile Extrusion Line?

For quick questions or general price ranges, feel free to use the Quick Contact Sidebar on the right (or bottom on mobile).

However, for a precise configuration-based quotation and factory layout drawing, we recommend providing your specific requirements.

Why Leading LED Lighting Manufacturers Trust Jinxin for PC/PMMA Profile Production

Supplier to Global Leaders

Jinxin extruders operate inside the factories of top international groups. We pass their rigorous Vendor Audits—bringing enterprise-grade reliability to your plant. (Client names protected by NDA).

Factory Direct

No middlemen. We own the Software Source Codes & Mechanical Drawings, ensuring lifetime support for upgrades.

CE Certified & Tax-Saving Support

CE Certified equipment. We configure the line to meet your target pipe standards (e.g., ISO 15874) upon request. We also provide Certificate of Origin to help minimize your import duties.

Dedicated to Single Screw Extrusion Since 2012

Jinxin focuses exclusively on single-screw technology. This specialized focus allows us to refine machine stability and output efficiency to the absolute highest standard across our entire range of extrusion lines.

We deliver enterprise-grade equipment that passes the rigorous audits of international groups. Whether you are a startup or an industry giant, we combine precision engineering with factory-direct value, empowering your production to scale without compromise.

Get Your Configuration-Based Quotation

Provide your production targets below. Our engineers will design the layout (P&ID) and calculate the precise factory-direct price for you.