Ligne d'extrusion de profilés plastiques sur mesure

Une plateforme d'extrusion modulaire adaptée à votre polymère - TPU, PP, PE, PVC ou ABS. Spécialisé dans Co-extrusion (bicolore / souple-dur) et des voies de dimensionnement de précision pour répondre à vos conceptions de profilés les plus complexes.

L'ingénierie de votre réussite : Le processus de personnalisation à vis unique

Jinxin Extruder configure chaque ligne de profilés à partir de votre dessin, de la qualité du matériau et des critères d'acceptation, plutôt que de proposer une configuration “standard”. Notre flux de travail d'ingénierie aligne la conception de la vis, la filière/l'outillage et les modules en aval sur vos besoins en matière de géométrie, de surface cible et de stabilité de la forme. (Le PVC n'est pris en charge que sous forme de granulés).

Examen du comportement des matériaux

Confirmer le type de résine et la fenêtre de traitement (composé PVC / PP / PE / TPU / ABS) pour définir l'approche de la conception de la vis et la stabilité de l'apport de matière fondue.

Filière de profilage et équilibre des flux

L'outillage est conçu en fonction de votre section transversale et de l'épaisseur asymétrique des parois afin de garantir un flux constant et une stabilité dimensionnelle.

Sélection du module aval

Choisissez le refroidissement direct à l'eau ou l'étalonnage sous vide, ainsi que les modules de transport, de découpe et d'alignement en option en fonction de la rigidité du profil et de la priorité de verrouillage de la forme.

Liens rapides vers vos solutions matérielles

Composants de la ligne d'extrusion de profilés en plastique (Bibliothèque de modules configurés)

Les modules ci-dessous forment la ligne, la configuration finale variant en fonction du matériau, de la géométrie du profil et des exigences de dimensionnement ; les images sont données à titre indicatif.

Extrudeuse à vis unique haute performance

- Système d'entraînement : Siemens Beide + ABB ACS580 avec un contrôle stable de la vitesse pour l'extrusion continue de profilés.

- Vis et baril : Conception de la vis en fonction du matériau (configurée) avec fenêtre de processus adaptée au composé PVC / PP / PE / TPU / ABS.

- Chauffage et refroidissement : Commande de chauffage par relais statique (SSR) (FOTEK) avec régulation de la température multizone pour une température de fusion stable.

Unité de coextrusion (optionnelle / configurée)

- Module d'extrusion : Co-extrudeuse (configurée) dont la production est adaptée aux exigences de la structure de la couche (bicolore / couche de couverture / PVC souple+rigide).

- Système d'entraînement : Moteur standard + onduleur (configuré par la marque) avec contrôle synchronisé de la vitesse pour la stabilité de la couche.

- Intégration : Intégration de la ligne (configurée) avec des interfaces mécaniques et de contrôle alignées sur l'extrudeuse principale et l'outillage.

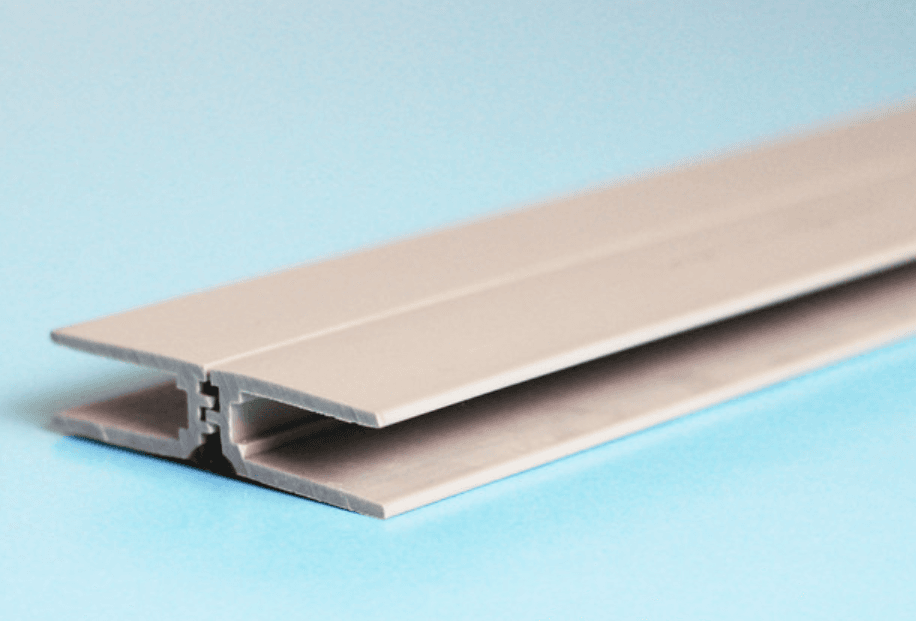

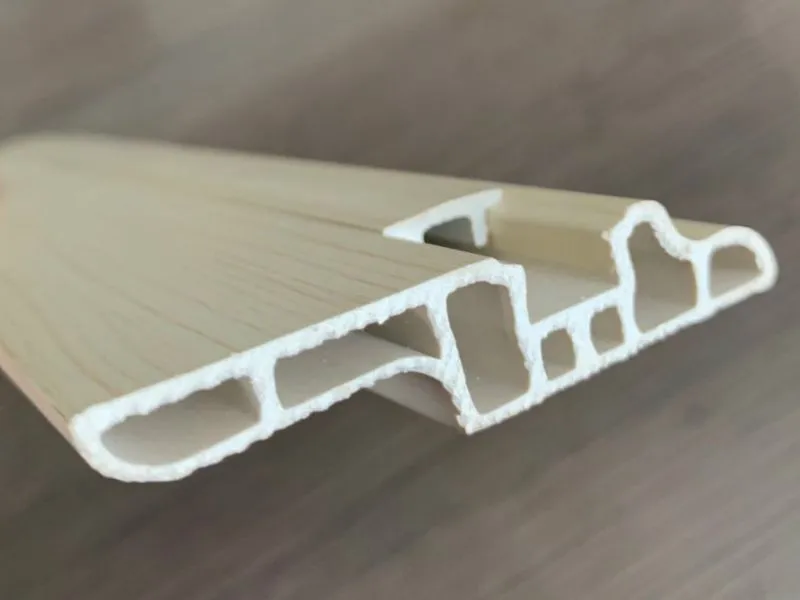

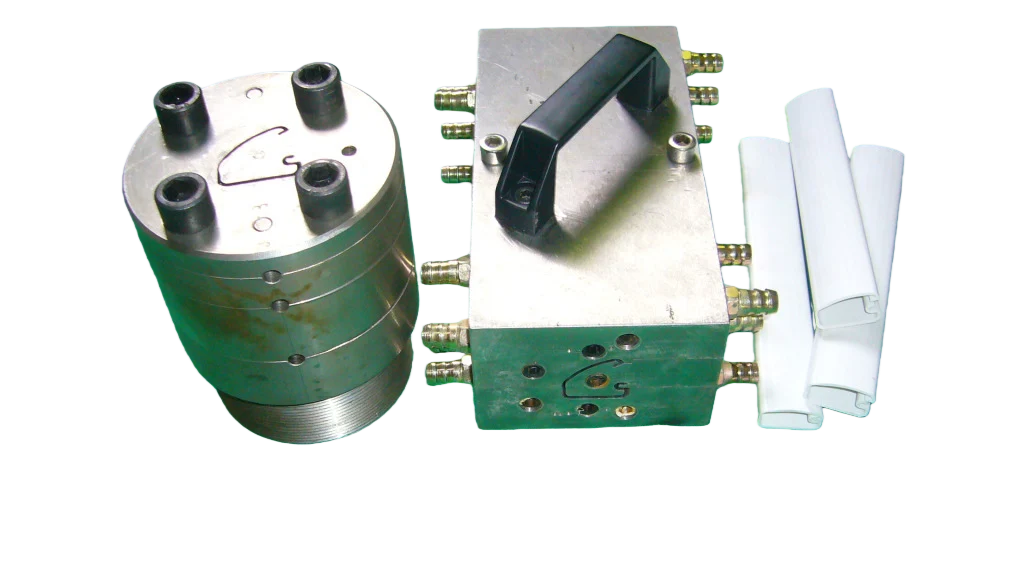

Outillage de profilage et de coextrusion (sur mesure)

- Conception de la matrice : Filière à profil personnalisé (configurée) avec des voies d'écoulement conçues en fonction de votre section transversale et de la répartition de l'épaisseur de la paroi.

- Interface de coextrusion : Outillage de co-extrusion (configuré) pour les structures bicolores, les couches de recouvrement ou les structures PVC souples et rigides (en fonction du produit).

- Équilibre des flux : Conception de la distribution du flux (configurée) pour favoriser une distribution uniforme de la matière fondue à travers les couches et réduire l'instabilité de l'interface (dépend de la compatibilité des matériaux et des paramètres).

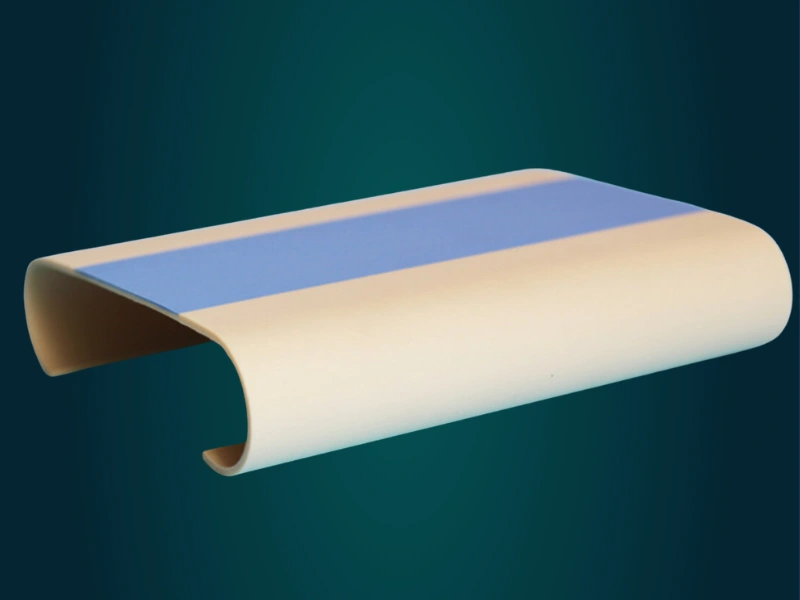

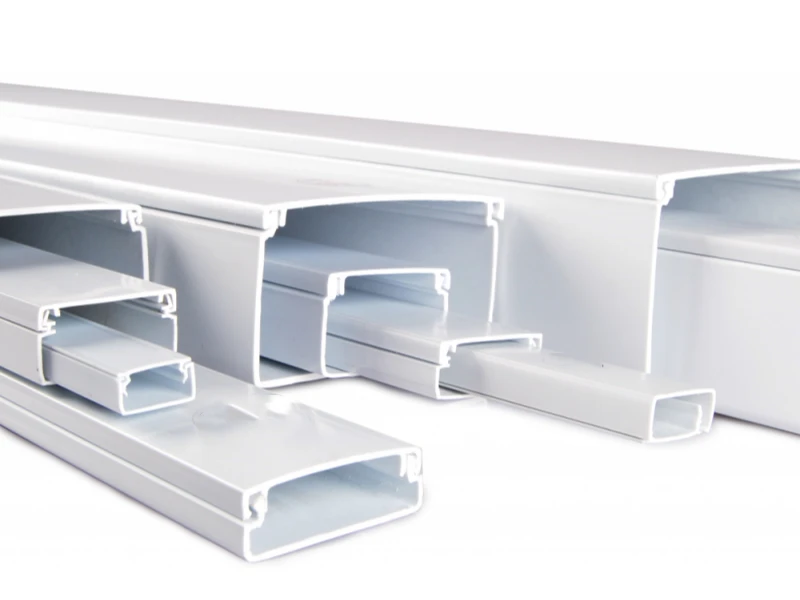

Options de dimensionnement : Dimensionnement libre ou étalonnage sous vide (configuré)

- Le dimensionnement libre du système de refroidissement : Refroidissement direct à l'eau (configuré) pour les profils dont l'aspect de surface est sensible au contact (en fonction du profil).

- Dimensionnement du vide : Outillage de calibrage + réservoir à vide (configuré) pour les profils creux/complexes nécessitant un verrouillage de la forme ; le calibrage sous vide en plusieurs étapes peut être configuré pour les géométries complexes.

- Gestion de l'eau et du vide : Boucle de refroidissement et stabilité du vide (configurées) avec surveillance pour une performance de dimensionnement cohérente (la configuration finale dépend de la géométrie du profil et des utilités du site).

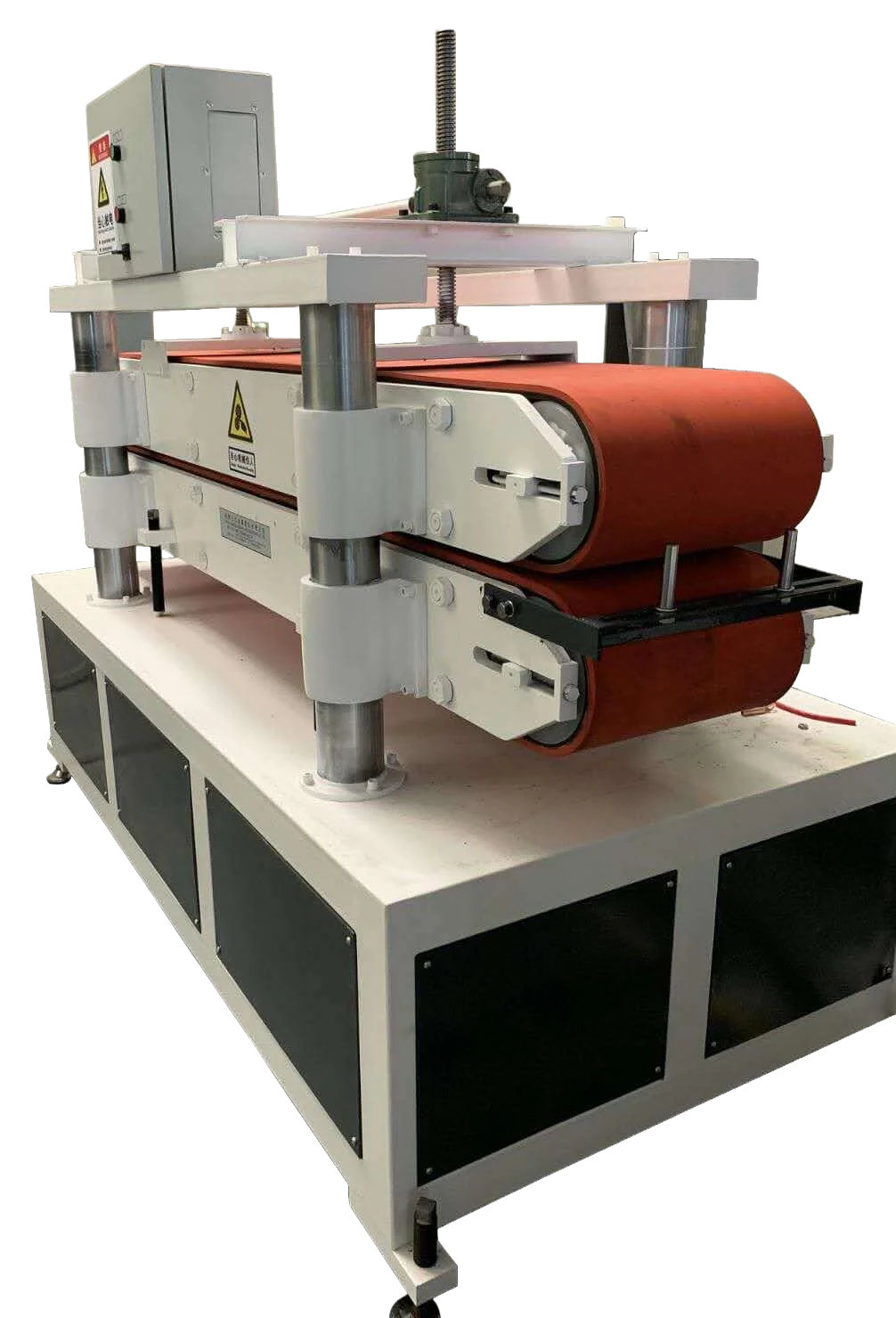

Unité de traction de précision (configurée)

- Type de traction : Dépose par courroie/caterpillar (configurée) adaptée à la rigidité du profil et à la sensibilité de la surface.

- Contrôle de la vitesse : Contrôle synchronisé de la vitesse (configuré) pour réduire les fluctuations d'épaisseur et les dérives dimensionnelles.

- La maintenabilité : Structure à réglage rapide et facile d'accès (configurée) pour le nettoyage et le changement de routine.

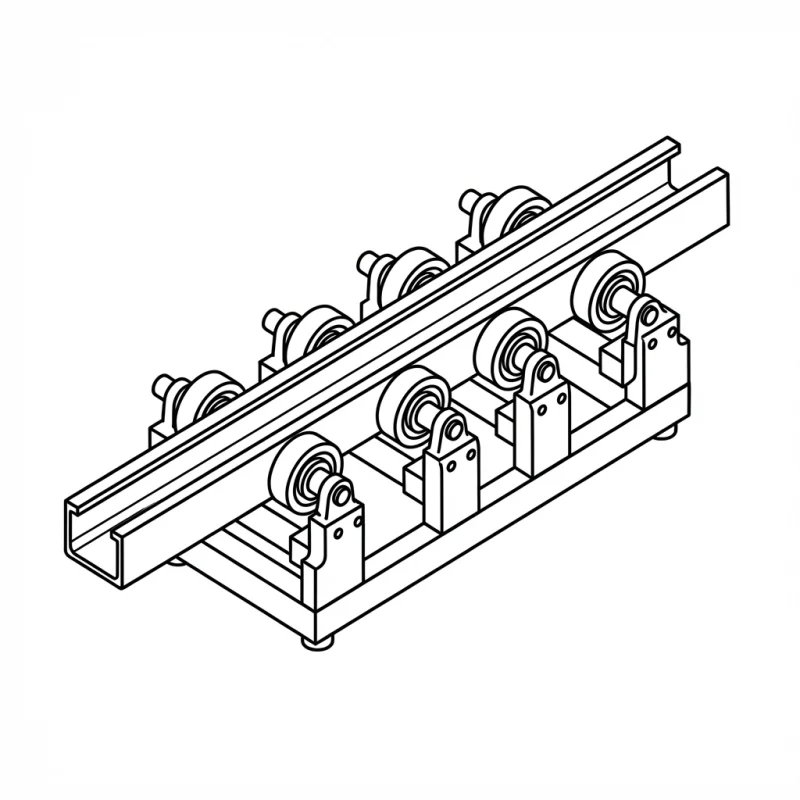

Redressement / Correction anti-torsion (en option / configuré)

- Module de correction : Dispositifs de redressement et d'alignement (configurés) pour les profilés susceptibles de se tordre, de se plier ou de se cambrer.

- Logique d'installation : Méthode d'ajustement (configurée) basée sur la complexité de la section transversale et l'exigence de stabilité.

- Placement : Placement du module (configuré) après dimensionnement/refroidissement en fonction du comportement du produit.

Découpage + Décollage + Empilage (Configuré)

- Méthode de coupe : Unité de coupe (configurée) adaptée à la rigidité du matériau, à l'épaisseur de la paroi et à la longueur cible.

- Manipulation : Décollage et empilage (configuré) pour une manipulation stable sans endommager la surface.

- Adaptation de la mise en page : Disposition en aval (configurée) en fonction de l'espace disponible dans l'usine et des préférences en matière d'emballage.

Prêt à obtenir un devis pour la configuration de votre ligne d'extrusion de profilés en plastique ?

Pour des questions rapides ou des fourchettes de prix générales, n'hésitez pas à utiliser le formulaire de demande d'informations. Barre latérale de contact rapide à droite (ou en bas sur mobile).

Toutefois, pour un devis précis basé sur la configuration et plan d'implantation de l'usine, nous vous recommandons de nous faire part de vos besoins spécifiques.

Ligne d'extrusion de profilés plastiques sur mesure FAQ par matériau (PVC / PP / PE / TPU / ABS)

Sélectionnez votre matériau ci-dessous pour voir les questions les plus courantes sur l'extrusion de profilés et les conseils de configuration.

FAQ sur le PVC (composé granulé seulement)

FAQ SUR LE PP ET LE PE

FAQ TPU

FAQ SUR L'APA

Dédié à l'extrusion à vis unique depuis 2012

Jinxin se concentre exclusivement sur la technologie à vis unique. Cette spécialisation nous permet d'affiner la stabilité de la machine et l'efficacité de la production pour atteindre les normes les plus élevées sur l'ensemble de notre gamme de lignes d'extrusion.

Nous fournissons des équipements de qualité professionnelle qui satisfont aux audits rigoureux des groupes internationaux. Que vous soyez une startup ou un géant de l'industrie, nous combinons une ingénierie de précision avec une valeur directe d'usine, permettant à votre production d'évoluer sans compromis.

Obtenez votre devis basé sur la configuration

Indiquez ci-dessous vos objectifs de production. Nos ingénieurs concevront l'implantation (P&ID) et calculeront pour vous le prix précis en usine.