Explore Extruder Machines by Plastic Extrusion Materials

Plastic Extrusion Materials

Our categorized approach helps you quickly find the best extrusion equipment for your specific plastic materials. We offer detailed information and specifications for machines compatible with PVC, PE, PP, PC, PA, and more. This method ensures you get the most efficient and effective solution tailored to your production requirements.

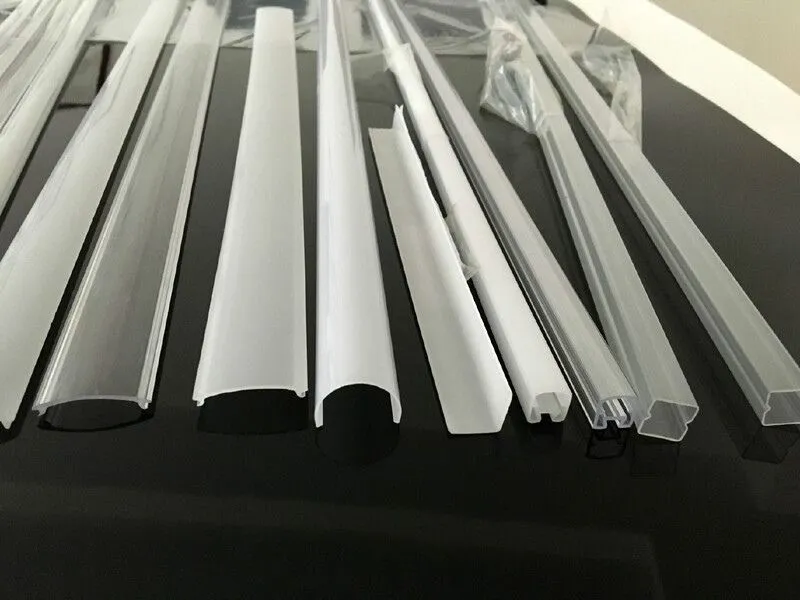

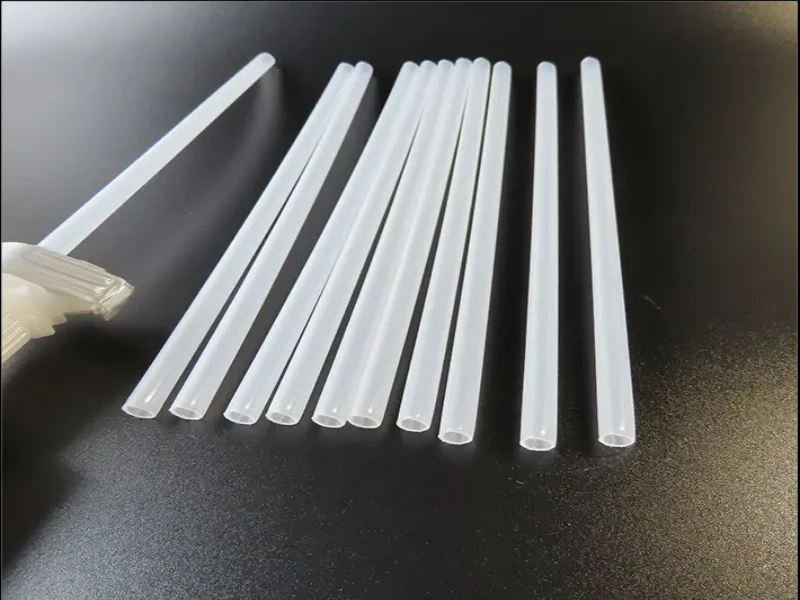

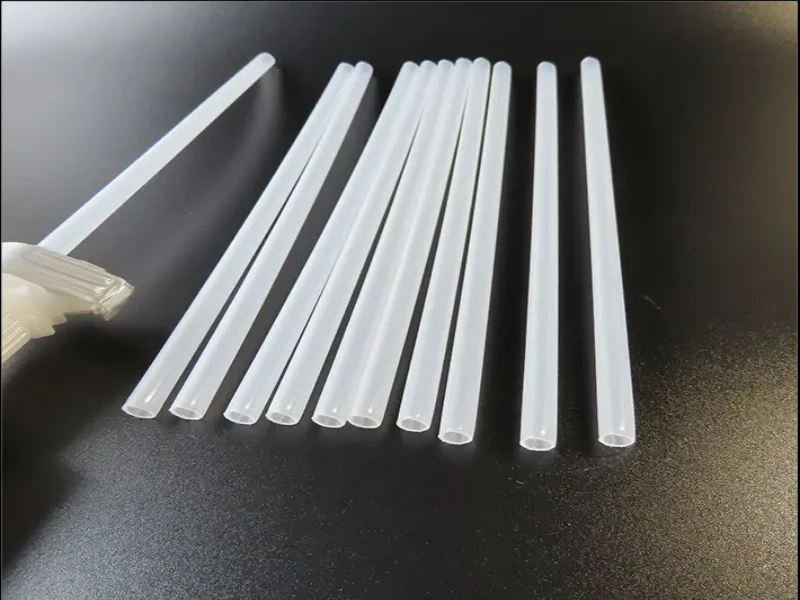

Polycarbonate (PC)

Polycarbonate (PC) is known for its exceptional impact resistance, clarity, and thermal stability. This versatile material is widely used in applications requiring high optical clarity and durability, such as LED lighting covers, automotive components, and electronic housings.

Extrusion Characteristics:

- High Impact Resistance: Suitable for applications requiring durability.

- Optical Clarity: Ideal for transparent applications like lighting covers and lenses.

- Thermal Stability: Maintains performance at high temperatures.

Applications:

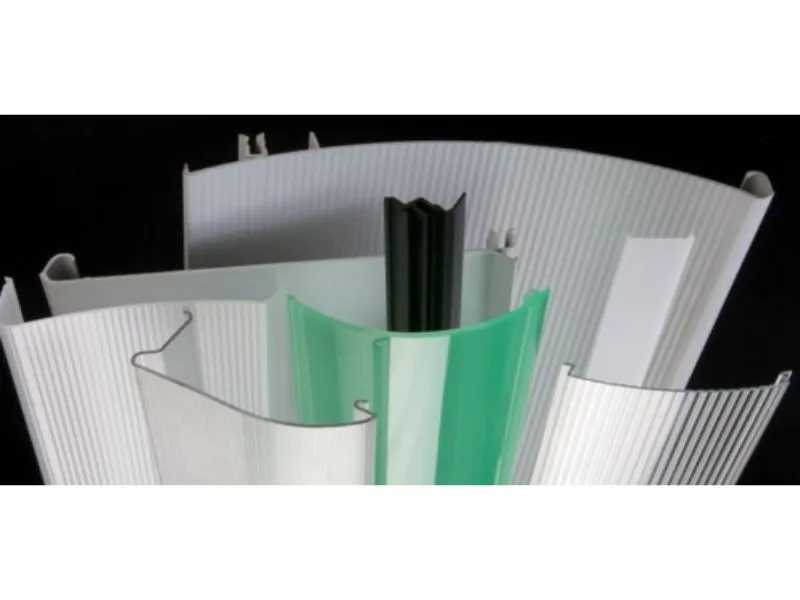

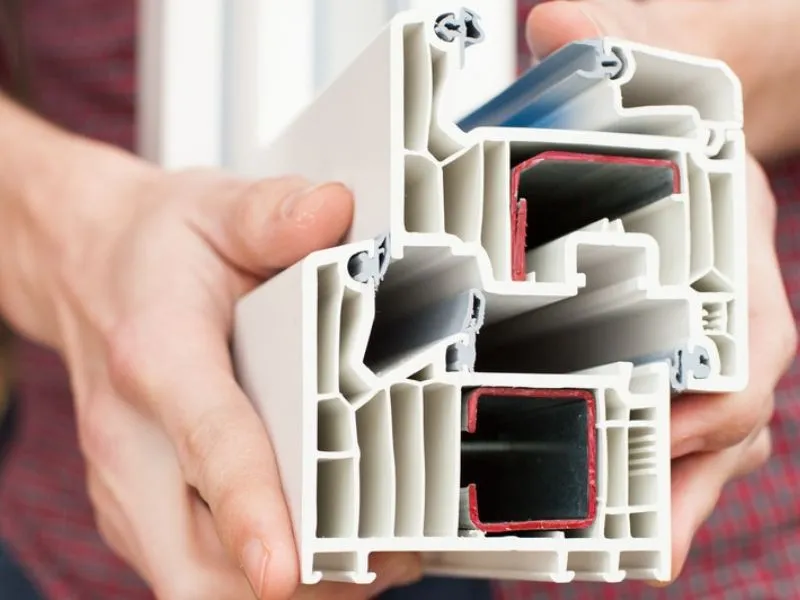

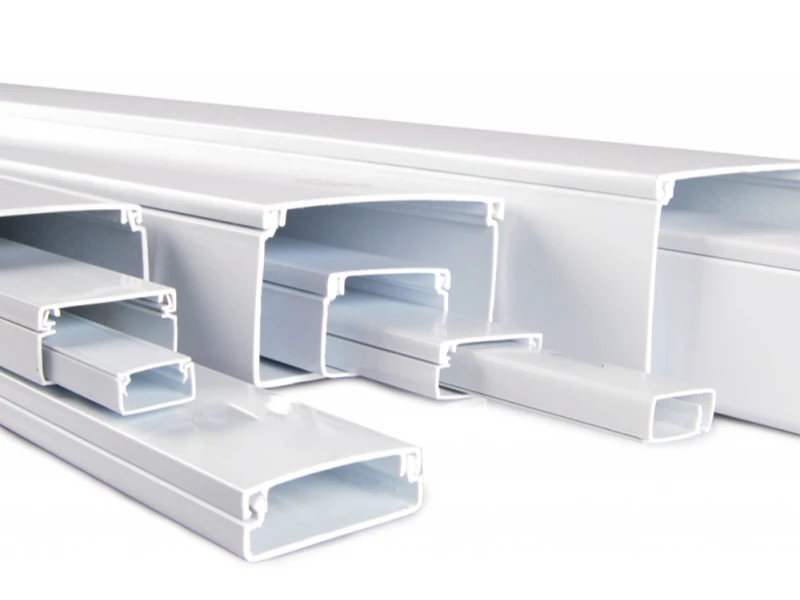

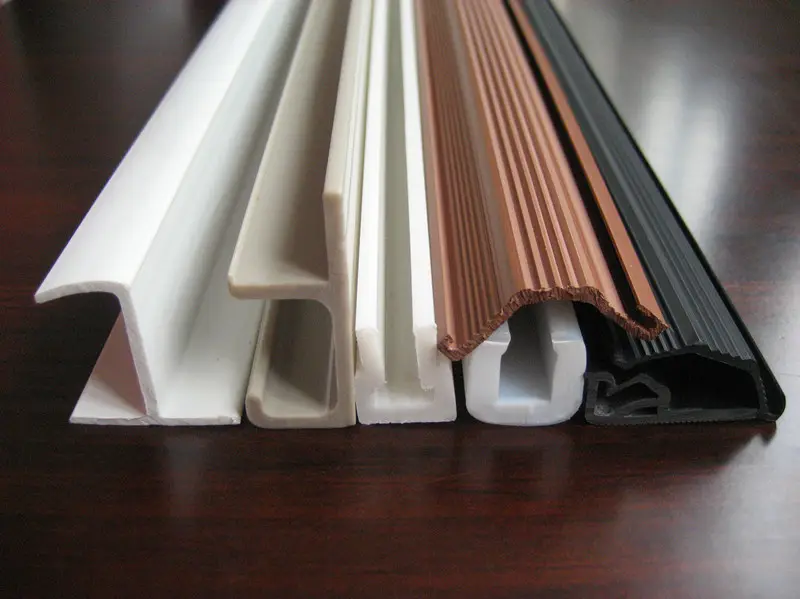

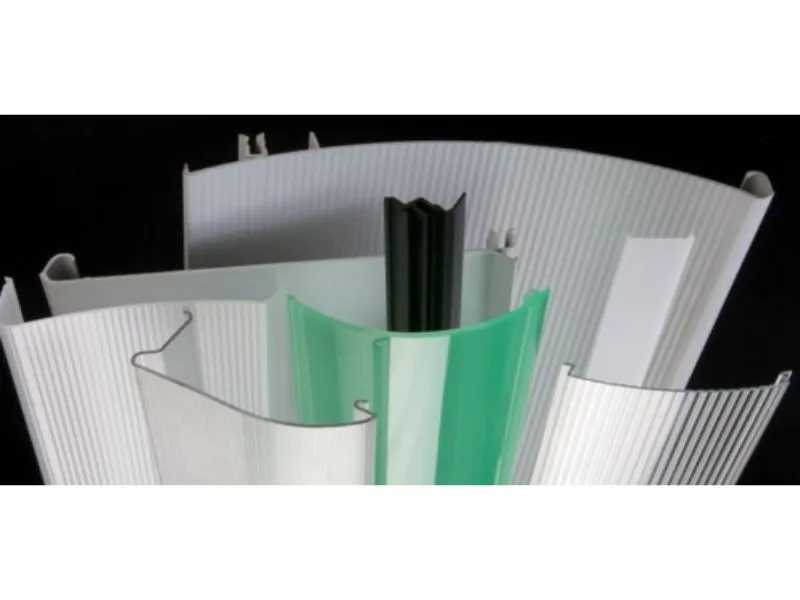

Polyvinyl Chlorid (PVC)

Polyvinyl Chloride (PVC) is a highly durable and versatile plastic, widely recognized for its excellent chemical resistance, weatherability, and cost-effectiveness. It is extensively used in construction, plumbing, electrical insulation, and more.

Extrusion Characteristics:

- Chemical Resistance: Withstands exposure to various chemicals.

- Weatherability: Suitable for outdoor applications.

- Durability: Long-lasting and low-maintenance.

Applications:

- Window and door profiles.

- Electrical conduits and trunking.

- Water and sewage pipes. (We can only offer single-screw extrusion machines for PVC granules. For more information, please contact us.)

Polyethylene (PE)

Polyethylene, commonly referred to by its abbreviation PE, is a versatile thermoplastic available in various forms, including High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE). Both types are characterized by their excellent toughness, chemical resistance, and flexibility, but they have distinct properties and applications.

High-Density Polyethylene (HDPE): Known for its high strength-to-density ratio, HDPE is a robust material that offers excellent chemical resistance and low moisture absorption. It is ideal for applications requiring durability and rigidity, such as water and gas pipes, plastic bottles, and geomembranes. HDPE can withstand high temperatures and harsh environmental conditions, making it suitable for outdoor applications.

Low-Density Polyethylene (LDPE): LDPE is recognized for its flexibility and ease of processing. It has a lower density than HDPE, which gives it a softer and more pliable nature. LDPE is commonly used in applications such as plastic bags, film wrap, and containers where flexibility and resilience are required. It also offers good impact resistance and is less prone to cracking under stress.

Extrusion Characteristics:

HDPE:

- High Strength and Rigidity: Ideal for products requiring structural integrity.

- Chemical Resistance: Suitable for harsh chemical environments.

- Applications: Water and gas pipes, plastic bottles, geomembranes.

LDPE:

- Flexibility and Toughness: Perfect for products needing pliability.

- Ease of Processing: Makes it suitable for thin films and flexible containers.

- Applications: Plastic bags, film wrap, flexible containers.

Applications:

Polypropylene (PP)

Polypropylene (PP) is a lightweight, chemically resistant plastic with excellent mechanical properties. It is commonly used in packaging, automotive components, and medical devices.

Extrusion Characteristics:

- High Melt Flow: Facilitates smooth extrusion.

- Chemical Resistance: Suitable for chemical handling applications.

- Mechanical Strength: Ideal for durable products.

Applications:

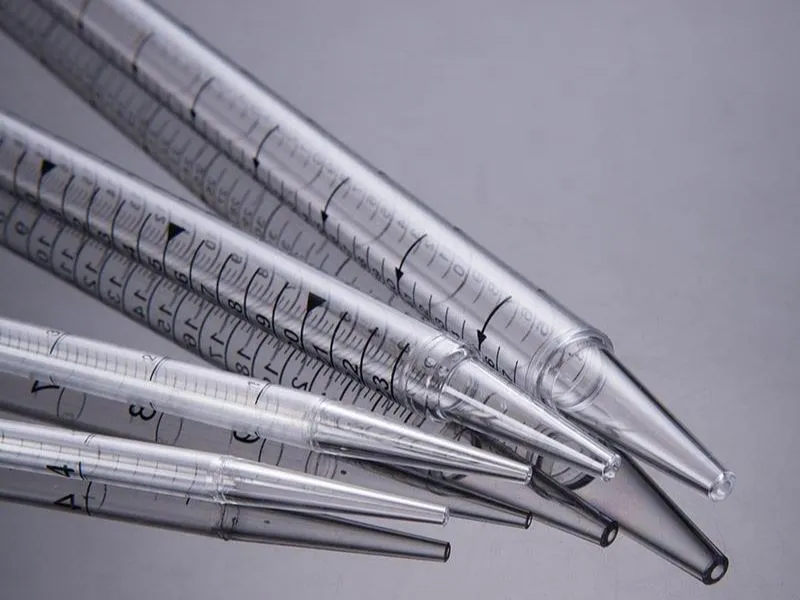

- Packaging bottles or pump, spray dip tube.

- Medical tubing and devices. (Not listed separately in this site, please contact us if you have any request.)

Polymethyl Methacrylate-Acrylic (PMMA)

Polymethyl Methacrylate (PMMA), also known as acrylic, is valued for its optical clarity, weatherability, and strength. It is commonly used in applications requiring high transparency and aesthetic appeal.

Extrusion Characteristics:

- High Clarity: Perfect for transparent applications.

- Weather Resistance: Suitable for outdoor use.

- Durability: Long-lasting and strong.

Applications:

Polyamide (PA)

Polyamide (PA), commonly known as nylon, is celebrated for its high tensile strength, abrasion resistance, and thermal stability. It is extensively used in the automotive industry, textiles, and industrial components.

Extrusion Characteristics:

- High Strength: Suitable for demanding applications.

- Abrasion Resistance: Ideal for wear-resistant parts.

- Thermal Stability: Performs well under high temperatures.

Applications:

Thermoplastic Elastomer (TPE)

Thermoplastic Elastomers (TPE) combine the properties of rubber and plastic, offering flexibility, durability, and ease of processing. TPE is widely used in automotive, consumer goods, and medical applications.

Extrusion Characteristics:

- Flexibility: Ideal for products requiring elasticity.

- Durability: Long-lasting and resilient.

- Ease of Processing: Suitable for complex shapes.

Applications:

Polystyrene (PS)

Polystyrene (PS) is a lightweight, cost-effective plastic known for its ease of processing and versatility. It is widely used in packaging, disposable cutlery, and insulation.

Extrusion Characteristics:

- Ease of Processing: Suitable for high-volume production.

- Lightweight: Ideal for portable and disposable products.

- Versatile: Can be used in various applications.

Applications:

EXTRUSION SOLUTIONS

Let's get in touch

Email Address

Factory Address

No. 31 Yuci Rd., Yuyao, Ningbo City, Zhejiang Province, China