TPE Tourniquet Extrusion Machine (also for Esmarch/Esmark Elastic Bandage)

High-precision TPE tourniquet extrusion for medical bands and Esmark bandages. A versatile 3-unit system featuring adjustable calendering, slitting, and perforation for spec-consistent rolls.

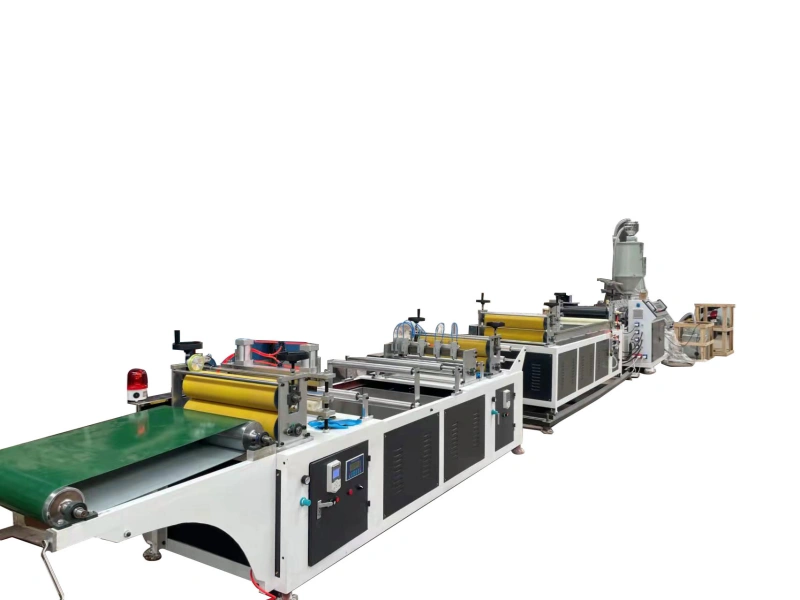

3-Unit Configuration for TPE Tourniquet Extrusion Line

To ensure stable production of sensitive TPE materials, this line is divided into three specialized units that handle everything from raw material melting to the final perforated roll.

High-Stability Extrusion Station

- Drive System: Siemens Beide motor with ABB 580 series high-performance inverter.

- Drive: Direct Coupling (No Belts, Maintenance-Free)

- FAT with 9-Zone Thermal Baseline: We record the precise 9-zone temperature profile required to prevent TPE degradation, providing you a “golden recipe” for consistent thickness and surface quality.

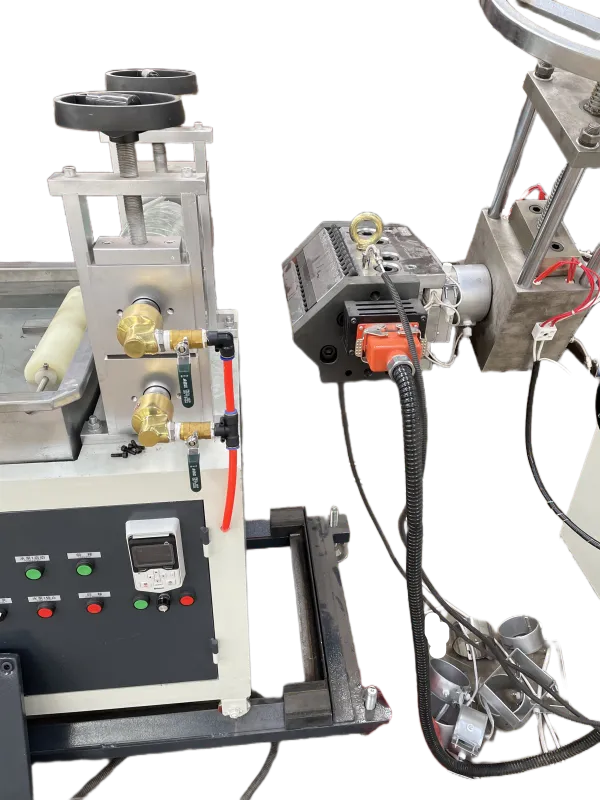

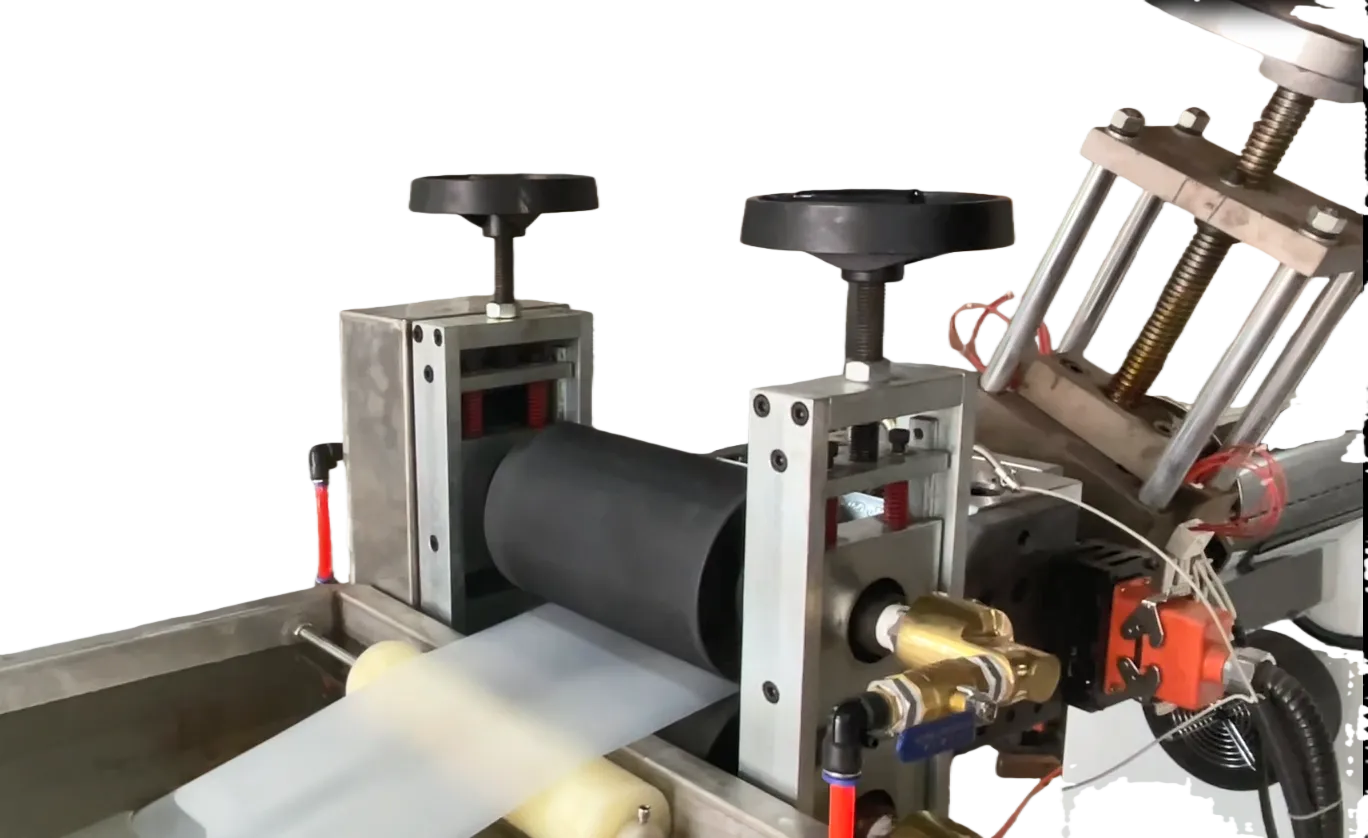

2-Roll Calendering & Cooling Station

- Precision Calendering: Two-roll press system allows users to manually adjust the sheet to the exact target thickness.

- Anti-Stick Technology: Rollers are Teflon-coated with internal water cooling to handle high-oil TPE formulas without sticking.

- Cooling Path: Stainless steel water tank with an independent motor and ABB inverter.

- Interchangeable Surface Rollers: We provide a choice of smooth or textured (patterned) calendering rollers. To produce both standard smooth bands and anti-slip textured tourniquets

Slitting & Perforation Cutting Station

- W-Path Swing Arms: A 4-arm Dancer Arm buffer system that absorbs tension fluctuations, ensuring the elastic TPE is never stretched or deformed.

- Precision Slitting: Adjustable pneumatic slitting blades to divide the wide sheet into multiple tourniquets or wide Esmarch bandages.

- Point-Link Perforation: Computer-controlled cutting with encoder for fixed-length accuracy; produces professional “pull-and-tear” rolls with length-arrival alarms.

Ready to Configure Your TPE Tourniquet Extrusion Line?

For quick questions or general price ranges, feel free to use the Quick Contact Sidebar on the right (or bottom on mobile).

However, for a precise configuration-based quotation and factory layout drawing, we recommend providing your specific requirements.

Why Manufacturers & Procurement Leaders Choose Jinxin

Supplier to Global Leaders

Jinxin extruders operate inside the factories of top international groups. We pass their rigorous Vendor Audits—bringing enterprise-grade reliability to your plant. (Client names protected by NDA).

Factory Direct

No middlemen. We own the Software Source Codes & Mechanical Drawings, ensuring lifetime support for upgrades.

CE Certified & Tax-Saving Support

CE Certified equipment. We configure the line to meet your target pipe standards (e.g., ISO 15874) upon request. We also provide Certificate of Origin to help minimize your import duties.

Dedicated to Single Screw Extrusion Since 2012

Jinxin focuses exclusively on single-screw technology. This specialized focus allows us to refine machine stability and output efficiency to the absolute highest standard across our entire range of extrusion lines.

We deliver enterprise-grade equipment that passes the rigorous audits of international groups. Whether you are a startup or an industry giant, we combine precision engineering with factory-direct value, empowering your production to scale without compromise.

Get Your Configuration-Based Quotation

To provide an accurate quote for your TPE tourniquet extrusion line, please provide: