Custom Plastic Profile Extrusion Line

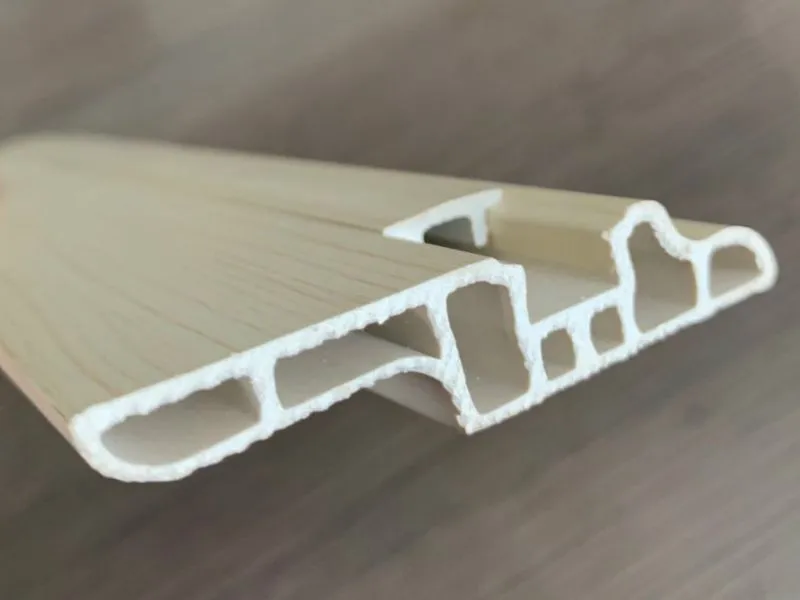

A modular extrusion platform tailored to your polymer—TPU, PP, PE, PVC, or ABS. Specialized in Co-extrusion (Dual-color / Soft-Hard) and precision sizing routes to match your most complex profile designs.

Engineering Your Success: The Single-Screw Customization Process

Jinxin Extruder configures each profile line from your drawing, material grade, and acceptance criteria—rather than offering a “standard” setup. Our engineering workflow aligns screw design, die/tooling, and downstream modules to your geometry, surface target, and shape stability needs. (PVC is supported as pelletized compound only.)

Material Behavior Review

Confirm resin type and processing window (PVC compound / PP / PE / TPU / ABS) to define the screw design approach and stable melt delivery.

Profile Die & Flow Balance

Tooling is designed around your cross-section and asymmetric wall thickness to support consistent flow and dimensional stability.

Downstream Module Selection

Choose free-sizing direct-to-water cooling or vacuum calibration, plus haul-off, cutting, and optional alignment modules based on profile rigidity and shape-lock priority.

Quick Links to Your Material Solutions

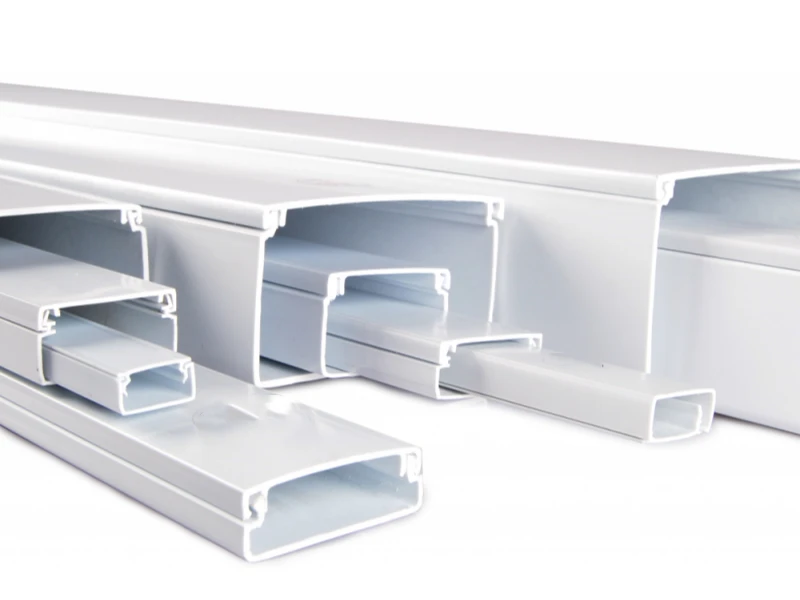

Plastic Profile Extrusion Line Components (Configured Module Library)

The modules below form the line, with final configuration varying by material, profile geometry, and sizing requirement; images are for reference only.

High-Performance Single-Screw Extruder

- Drive System: Siemens Beide + ABB ACS580 inverter with stable speed control for continuous profile extrusion.

- Screw & Barrel: Material-driven screw design (configured) with process window matched to PVC compound / PP / PE / TPU / ABS.

- Heating & Cooling: Solid state relay (SSR) heating control (FOTEK) with multi-zone temperature regulation for stable melt temperature.

Co-Extruder Unit (Optional / Configured)

- Extruder Module: Co-extruder (configured) with output matched to layer structure requirements (dual-color / cap layer / soft+rigid PVC).

- Drive System: Standard motor + inverter (brand configured) with synchronized speed control for layer stability.

- Integration: Line integration (configured) with mechanical + control interfaces aligned to the main extruder and tooling.

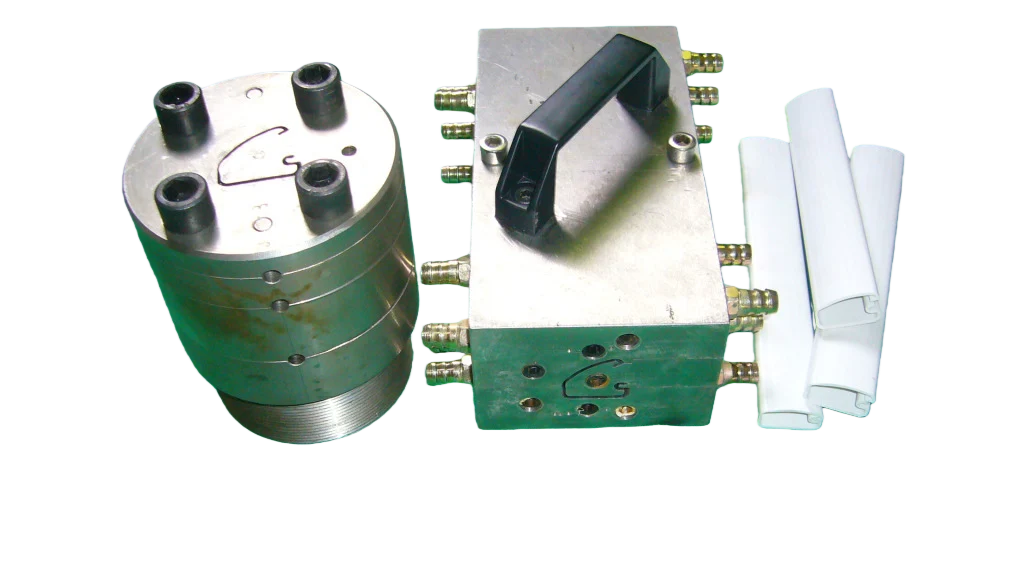

Profile Die & Co-Extrusion Tooling (Custom-Designed)

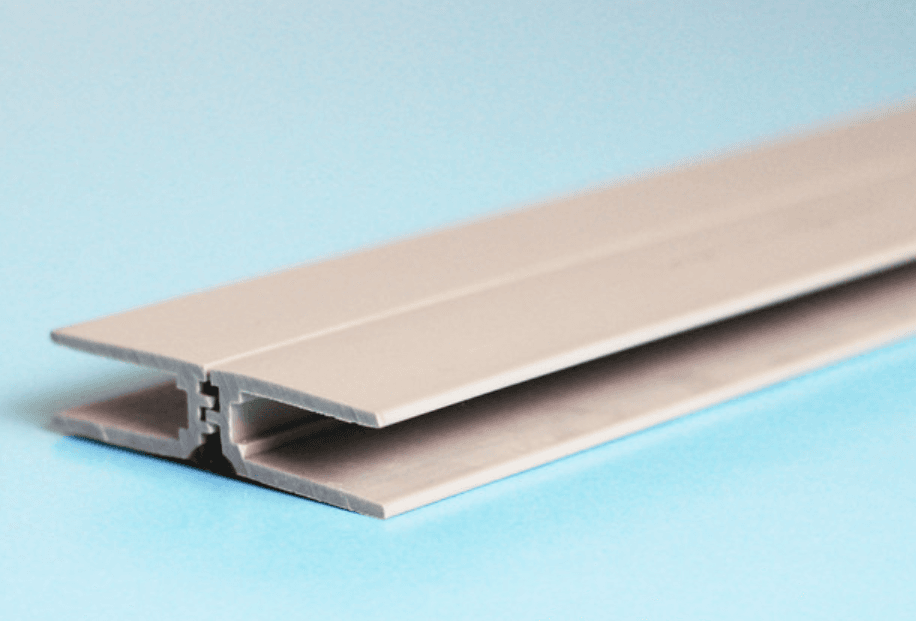

- Die Design: Custom profile die (configured) with flow paths engineered around your cross-section and wall thickness distribution.

- Co-Extrusion Interface: Co-extrusion tooling (configured) for dual-color, cap layer, or soft+rigid PVC structures (product-dependent).

- Flow Balance: Flow distribution design (configured) to support uniform melt delivery across layers and reduce interface instability (depends on material compatibility and settings).

Sizing Options: Free-Sizing or Vacuum Calibration (Configured)

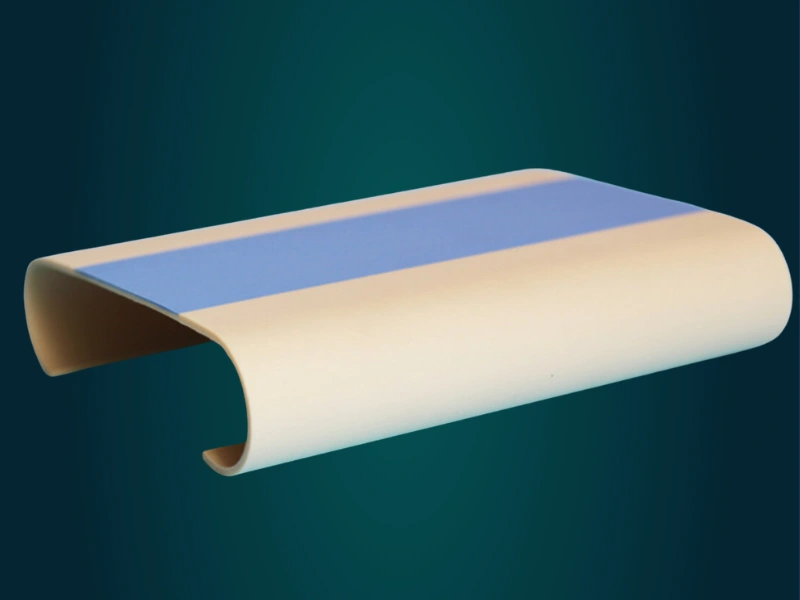

- Free-Sizing Cooling: Direct-to-water cooling (configured) for profiles where surface appearance is contact-sensitive (profile-dependent).

- Vacuum Sizing: Calibration tooling + vacuum tank (configured) for hollow/complex profiles requiring shape lock; multi-stage vacuum sizing can be configured for complex geometries.

- Water & Vacuum Management: Cooling loop and vacuum stability (configured) with monitoring for consistent sizing performance (final setup depends on profile geometry and site utilities).

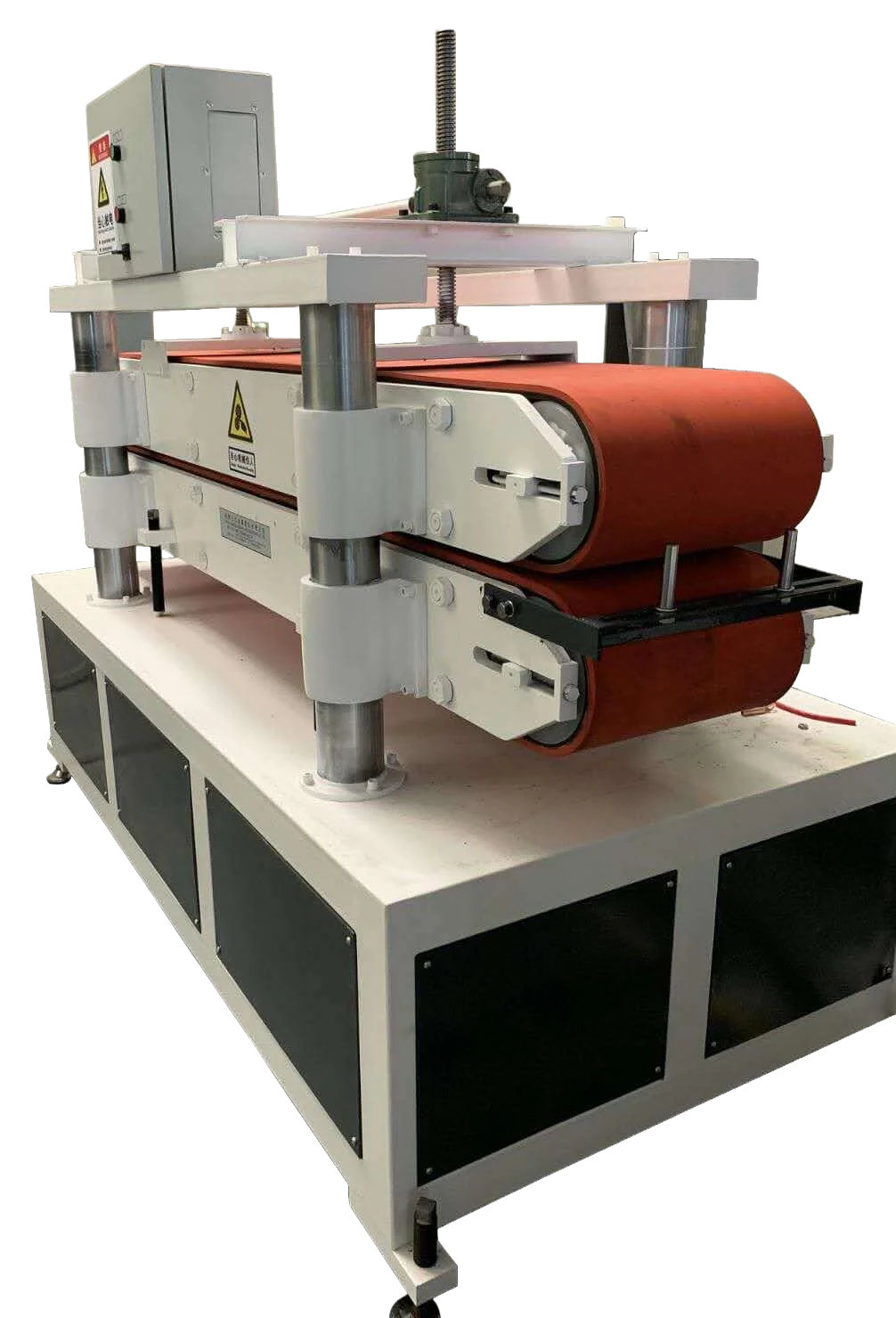

Precision Haul-Off / Traction Unit (Configured)

- Traction Type: Belt/caterpillar haul-off (configured) matched to profile rigidity and surface sensitivity.

- Speed Control: Synchronized speed control (configured) to reduce thickness fluctuation and dimensional drift.

- Maintainability: Quick-adjust and access-friendly structure (configured) for routine cleaning and changeover.

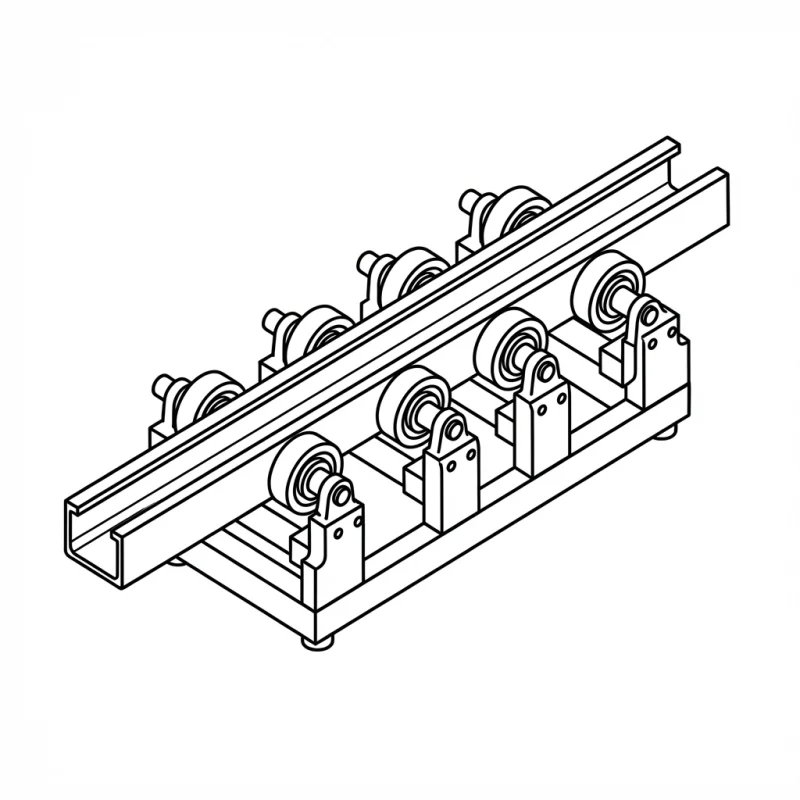

Straightening / Anti-Twist Correction (Optional / Configured)

- Correction Module: Straightening and alignment devices (configured) for profiles prone to twist, bend, or camber.

- Setup Logic: Adjustment method (configured) based on cross-section complexity and stability requirement.

- Placement: Module placement (configured) after sizing/cooling according to product behavior.

Cutting + Take-Off + Stacking (Configured)

- Cutting Method: Cutting unit (configured) matched to material rigidity, wall thickness, and target length.

- Handling: Take-off and stacking (configured) for stable handling without surface damage.

- Layout Fit: Downstream layout (configured) based on plant space and packaging preference.

Air-Cooled Industrial Chiller

- Function: Closed-Loop Water Cooling System

- Advantage: No Civil Water Pool Needed

- Install: Plug-and-Play Design

- Result: Constant Temperature = Stable Pipe Size

Ready to Get a Quote for Your Plastic Profile Extrusion Line Configuration?

For quick questions or general price ranges, feel free to use the Quick Contact Sidebar on the right (or bottom on mobile).

However, for a precise configuration-based quotation and factory layout drawing, we recommend providing your specific requirements.

Why Manufacturers & Procurement Leaders Choose Jinxin

Supplier to Global Leaders

Jinxin extruders operate inside the factories of top international groups. We pass their rigorous Vendor Audits—bringing enterprise-grade reliability to your plant. (Client names protected by NDA).

Factory Direct

No middlemen. We own the Software Source Codes & Mechanical Drawings, ensuring lifetime support for upgrades.

CE Certified & Tax-Saving Support

CE Certified equipment. We configure the line to meet your target pipe standards (e.g., ISO 15874) upon request. We also provide Certificate of Origin to help minimize your import duties.

Dedicated to Single Screw Extrusion Since 2012

Jinxin focuses exclusively on single-screw technology. This specialized focus allows us to refine machine stability and output efficiency to the absolute highest standard across our entire range of extrusion lines.

We deliver enterprise-grade equipment that passes the rigorous audits of international groups. Whether you are a startup or an industry giant, we combine precision engineering with factory-direct value, empowering your production to scale without compromise.

Get Your Configuration-Based Quotation

Provide your production targets below. Our engineers will design the layout (P&ID) and calculate the precise factory-direct price for you.