Polyamide (PA), commonly known as nylon, is a versatile material extensively used in the extrusion of various tubes. PA nylon tubes are manufactured using specific types of polyamide resins, such as PA6, PA66, and PA1010. These resins, when processed through extrusion equipment, melt and are molded into tubes. Typically, single screw extruders are employed for the PA extrusion of smaller diameter tubes.

PA tubes are known for their non-toxicity, semi-transparency, smooth yet tough surface, lightweight, good self-lubricating, and wear-resistant properties. However, they have inferior electrical properties. Chemically stable, they are unaffected by weak acids, weak bases, and oils but can dissolve in phenols and concentrated inorganic acids. PA tubes are widely used in automotive brake lines, instrument wires, air conditioning systems, irrigation control systems, textile factories, food factories, fuel conveyance in vehicles and ships, vacuum systems, oscillation insulators, static insulators, and more. They can be used in oil temperatures ranging from 80-100°C for extended periods.

PA Nylon Tube Extrusion Line Composition:

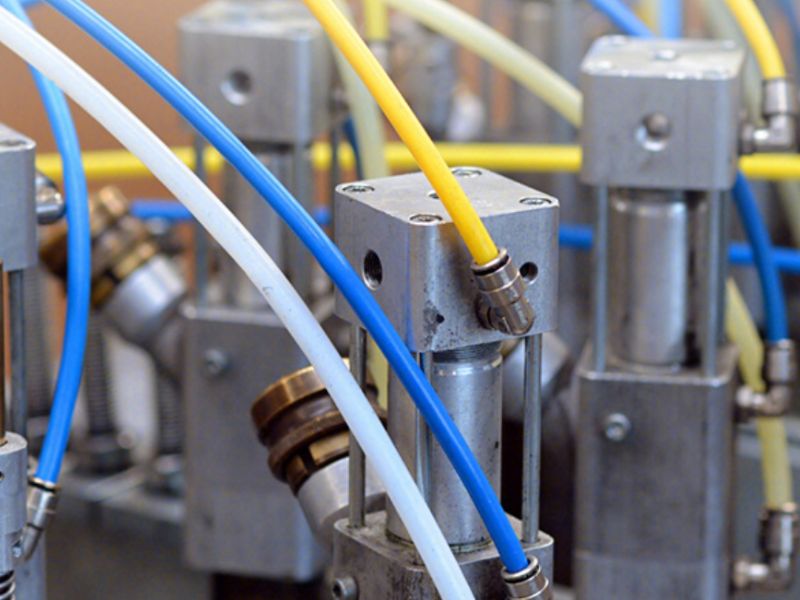

The extrusion line for PA nylon tubes typically includes a single screw extruder, die, vacuum sizing water tank, tractor/haul-off machine, and cutting machine/coiler.

Issues To Pay Attention To During PA Extrusion Production

- Drying Conditions:

- To prevent oxidation discoloration of the nylon resin during drying, vacuum drying is preferred. Post-drying, the moisture content should be below 0.3%.

- Extruder Requirements for PA Nylon Tubes:

- The extruder should have a drying hopper to prevent re-moistening of the resin. The screw should be a barrier type, with either a full-thread or mixing head design, to enhance mixing effects. The L/D ratio should be greater than 25, with the feed and metering sections being approximately the same length. The compression section should be 3-4 pitches long with a compression ratio of 3.0-4.0. Due to the low viscosity of the nylon melt, a larger draw ratio is needed in the die design, with a stretch ratio of 1.4-3.0 for PA nylon tubes.

- Cooling and Sizing of PA extrusion:

- For smaller diameter tubes, the extruded material can be directly cooled in water baths. The cooling water temperature should be between 15-22°C. Larger diameter tubes may require vacuum sizing for accurate dimensions.

- Temperature Settings in Extrusion:

- The feed section temperature should be near the melting point of the nylon resin to improve solid transport efficiency and degassing.

- The compression and metering sections should have temperatures set 10-30°C above the resin melting point to ensure uniform flow.

- The head and die temperatures should be lower than the metering section to stabilize the molding process.

The following is the PA6 and PA66 and PA1010 extrusion production table of commonly used extrusion molding temperatures:

| AREAS | PA6 | PA6 | PA66 | PA1010 |

|---|---|---|---|---|

| Medium Viscosity | High Viscosity | |||

| Feed Section | 200℃-230℃ | 200℃-230℃ | 230℃-260℃ | 250℃-260℃ |

| Compression Sector | 240℃-260℃ | 250℃-270℃ | 270℃-290℃ | 260℃-270℃ |

| Measurement Segment | 240℃-260℃ | 250℃-270℃ | 270℃-20℃ | 260℃-280℃ |

| Head | 230℃-250℃ | 240℃-260℃ | 270℃-20℃ | 220℃-240℃ |

Common Challenges in PA Extrusion:

- Moisture Sensitivity and Degradation:

- Challenge: PA nylon's hygroscopic nature can lead to moisture absorption, causing hydrolytic degradation during processing. This results in a decrease in mechanical properties and can lead to surface defects.

- Solution: Implement rigorous pre-drying procedures and maintain a controlled environment in the hopper and feed zones. Use desiccant dryers to ensure that the resin's moisture content is kept below the critical threshold.

- Thermal Stability:

- Challenge: PA nylon has a narrow processing window and is prone to thermal degradation if overheated, leading to discoloration and loss of properties.

- Solution: Precise temperature control throughout the extrusion process is essential. Utilizing advanced extrusion machinery equipped with precise heating and cooling systems can help maintain the optimal processing temperature.

- Melt Fracture and Die Swell:

- Challenge: High shear rates in the extruder can cause melt fracture, leading to surface roughness. Additionally, die swell can occur due to the elastic nature of the molten polymer, affecting the dimensional accuracy of the extruded tube.

- Solution: Optimizing the screw design to reduce shear stress and using a die with an appropriate land length can minimize these issues. Employing a post-extrusion sizing equipment can also help achieve the desired dimensions.

- Uniformity in Physical Properties:

- Challenge: Achieving uniform physical properties along the length of the tube, especially in thinner-walled tubes, can be challenging.

- Solution: Employing a barrier screw design can improve mixing and homogenization of the melt. Consistent feedstock quality and precise control of the extrusion parameters are also crucial.

- Color Consistency in Colored Tubes:

- Challenge: For colored PA nylon tubes, achieving a consistent color throughout the batch can be challenging, especially when changing colors between production runs.

- Solution: Use masterbatch pellets with a high concentration of pigments for uniform color dispersion. Implement thorough cleaning procedures during color changeovers to prevent contamination.

- Managing Post-Extrusion Shrinkage:

- Challenge: PA nylon tends to shrink upon cooling, which can affect the dimensional accuracy of the tube.

- Solution: Using a vacuum sizing tank to control the dimensions during the cooling process can compensate for the shrinkage. Adjusting the cooling rate and temperature can also help manage shrinkage levels.

Conclusion:

Understanding and controlling key variables in the extrusion process, such as material pre-treatment, screw design, temperature control, cooling speed, and stretching speed, is crucial for high-quality PA nylon tube production. Addressing these challenges requires a series of experiments and adjustments to find the best production conditions. Our PA extrusion process, with its emphasis on precise control and innovative solutions, represents the pinnacle of manufacturing excellence in the plastics industry.

Tags:

Extrusion Process (1) PA Extrusion (1) Plastic Extruders (3) Reinforced Hose (2) Success Projects (1) TPE Extrusion (1)

Related Product: