Single screw extruder vs twin screw extruder is a common topic in the plastic processing industry. Which one is more suitable for your needs?

Single screw and twin screw extruders serve different purposes in plastic processing. The right choice depends on your specific material requirements, production goals, and budget constraints. Understanding the key differences will help you make an informed decision for your manufacturing operation.

Single Screw vs Twin Screw Extruder: Which Suits Your Plastic Processing? 1

Single Screw vs Twin Screw Extruder: Which Suits Your Plastic Processing? 1

In this comprehensive guide, we’ll explore the fundamental differences between single screw and twin screw extruders, their respective advantages and applications, and provide expert insights to help you determine which technology best suits your production requirements.

What Is a Single Screw Extruder?

Single Screw vs Twin Screw Extruder: Which Suits Your Plastic Processing? 2

Single Screw vs Twin Screw Extruder: Which Suits Your Plastic Processing? 2

A single screw extruder uses one rotating screw in a heated barrel to melt and shape plastic materials into products like pipes, tubing, profile or films.

Single screw extruders are valued for their straightforward design. Plastic material, often pellets, enters a hopper and is fed into a barrel. Inside, a single screw rotates, pushing the material through three zones: the feed zone (material intake), compression zone (melting), and metering zone (uniform output). Heat from the barrel and friction melts the plastic, which is then shaped by a die.

These extruders are cost-effective, with lower purchase and maintenance costs than alternatives. Their simplicity makes them easy to operate, requiring minimal training, which suits smaller factories or those new to plastic processing. They’re reliable for processing uniform materials, producing consistent results for standard products.

However, single screw extruders have limited mixing capabilities. They rely on screw design for blending, which may not suffice for materials needing thorough mixing, like those with additives. Advances, such as barrier screws, improve mixing, but they don’t match the performance of more complex systems.

What Is a Twin Screw Extruder?

Single Screw vs Twin Screw Extruder: Which Suits Your Plastic Processing? 3

Single Screw vs Twin Screw Extruder: Which Suits Your Plastic Processing? 3

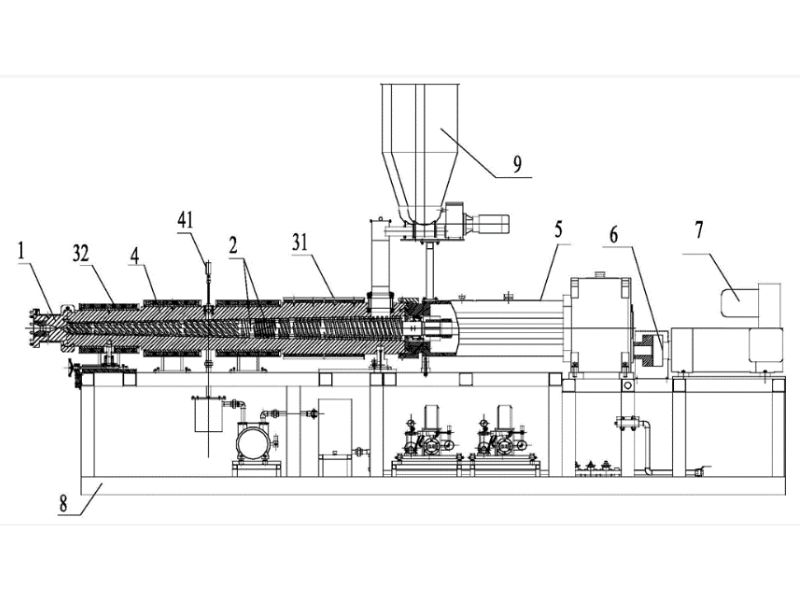

Figure shows is a schematic diagram of a twin-screw extruder suitable for large-diameter PVC-U double-wall corrugated pipes.

In the figure, the labels are: 1- machine head connector, 2- twin screw, 3- heating coil, 4- machine barrel, 5- distribution box, 6- coupler, 7- frequency conversion motor, 8- machine frame, 9- double hopper, 31- cast copper heating coil, 32- cast aluminum heating coil, 41- pressure gauge.

Twin screw extruders feature two screws rotating within a barrel, either in the same (co-rotating) or opposite (counter-rotating) directions. This design creates high shear forces, ensuring thorough mixing. Materials enter via a hopper, are melted, mixed, and extruded through a die, with precise control over temperature and pressure.

Their standout feature is superior mixing, ideal for blending additives, fillers, or heat-sensitive materials. They handle a wide range of plastics, making them versatile for specialized products. Twin screw extruders also offer high output and flexibility, supporting processes like compounding or recycling.

However, they’re more expensive and complex. Higher costs for purchase and maintenance, plus the need for skilled operators, can challenge smaller operations. Despite this, their performance often justifies the investment for high-value applications.

While Jinxin specializes in single screw extruders, we guide clients needing twin screw solutions, ensuring informed choices. For instance, we advised a client on twin screw options for a complex project while equipping their standard lines with our single screw extruders. Learn more at USEON.

Single Screw Extruder VS Twin Screw Extruder, What Are the Key Differences Between Them?

Knowing extruder differences is vital for efficient production. A wrong choice can lead to delays or excess costs. Let’s compare single and twin screw extruders to clarify their strengths.

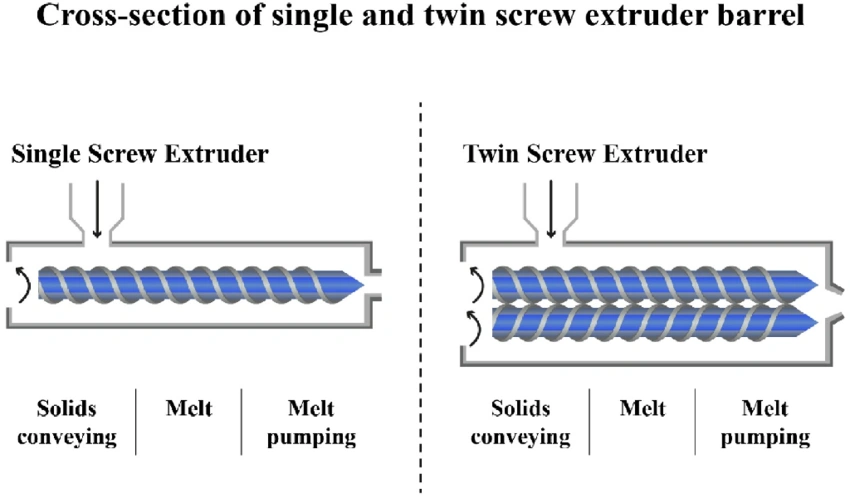

The primary difference lies in their design and operation. Single screw extruders use one rotating screw to transport, melt, and homogenize material, while twin screw extruders employ two intermeshing screws that can rotate in the same or opposite directions.

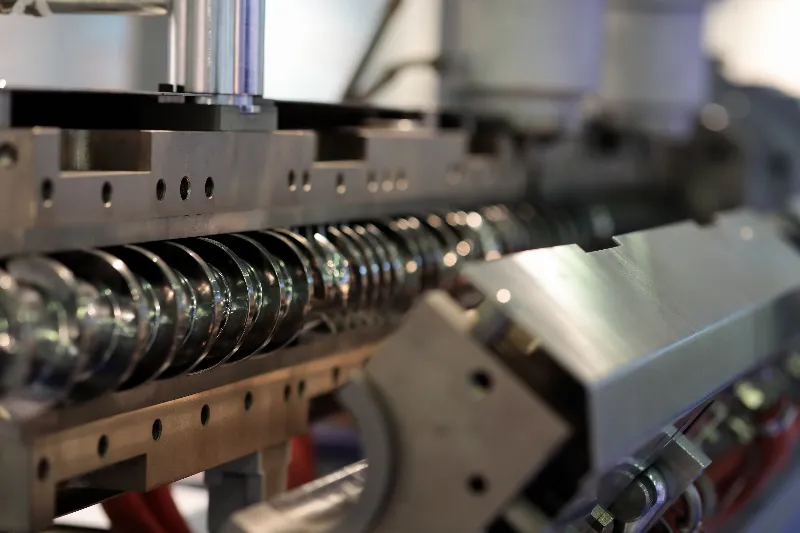

Single Screw inside

Single Screw inside

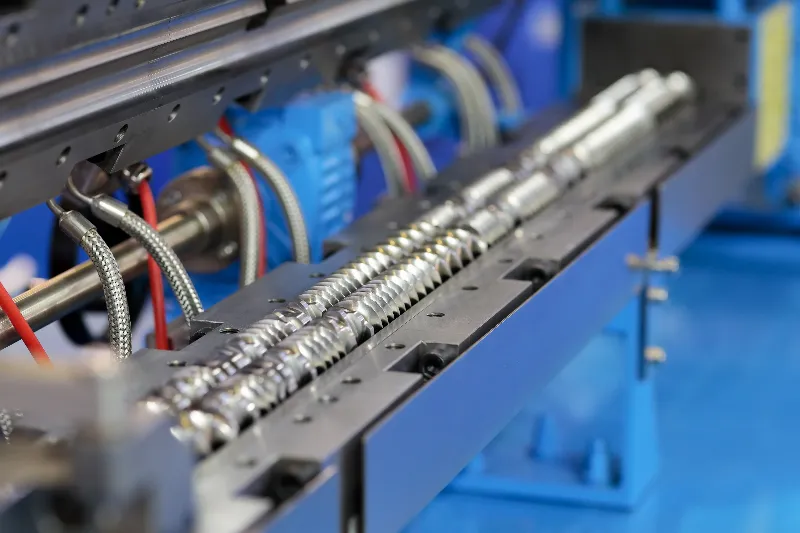

Twin screw inside

Twin screw inside

Design and Operational Differences

Single screw extruders feature a relatively simple design with one rotating screw inside a heated barrel. This simplicity makes them more straightforward to operate and maintain. The screw’s geometry is specifically designed to efficiently transport plastic material from the feed section through the compression and metering zones.

Twin screw extruders, on the other hand, contain two screws that can be configured in various ways:

- Co-rotating: Both screws rotate in the same direction

- Counter-rotating: Screws rotate in opposite directions

- Intermeshing: Screws have flights that engage with each other

- Non-intermeshing: Screws operate independently

These different configurations allow twin screw extruders to handle more complex processing tasks and materials that might be challenging for single screw machines.

The operational differences extend to how material moves through the extruder. In single screw machines, material transport relies primarily on friction between the material and barrel wall. Twin screw extruders use positive displacement, where material is actively pushed forward by the intermeshing screws, resulting in more consistent output regardless of material properties.

Material Processing Capabilities

The two extruder types handle materials differently, which significantly impacts their suitability for various applications:

| Feature | Single Screw Extruder | Twin Screw Extruder |

|---|

| Material Form | Excellent for pellets and granules | Better for powders, difficult-to-feed materials |

| Mixing Ability | Limited distributive mixing | Superior dispersive and distributive mixing |

| Heat Sensitivity | Longer residence time | Shorter, more controlled residence time |

| Additives | Basic additive incorporation | Complex formulations with multiple additives |

| Viscosity Range | Limited range | Wide viscosity range capability |

Single screw extruders excel at processing thermoplastic pellets and granules, making them ideal for PVC pellets, PE, and PP applications. Their simpler design provides reliable performance for consistent materials but may struggle with powders or materials that don’t feed well.

Twin screw extruders shine when processing PVC powder, heat-sensitive materials, or applications requiring intensive mixing. Their enhanced mixing capabilities make them suitable for compounding, material modification, and processing materials with varying viscosities.

How Do I Choose Between Single and Twin Screw Extruders for My Application?

Picking the wrong extruder can disrupt production or strain budgets. The right choice boosts efficiency and quality. Let’s guide you through selecting the best extruder for your needs.

Consider materials, product complexity, budget, and expertise to decide between single and twin screw extruders.

Application-Specific Considerations

Different plastic processing applications have unique requirements that may favor one extruder type over the other:

Profile Extrusion: Single screw extruders are often preferred for simple profile extrusion applications using pre-compounded materials. Their consistent output and pressure generation make them well-suited for producing pipes, tubes, and simple profiles.

Film and Sheet Extrusion: For basic film and sheet production using homogeneous materials, single screw extruders provide excellent consistency and output stability. However, for multi-layer or specialty films, twin screw extruders might offer advantages in material preparation.

Compounding and Material Modification: Twin screw extruders are the clear choice for compounding applications where intensive mixing is required. Their superior mixing capabilities make them ideal for incorporating additives, fillers, and reinforcements into base polymers.

Recycling Applications: When processing recycled materials with varying properties, twin screw extruders offer better handling of inconsistent feedstocks. Their enhanced mixing capabilities help homogenize recycled materials more effectively.

Material-Based Selection Criteria

The type of material you’re processing should heavily influence your extruder choice:

| Material Type | Recommended Extruder | Reasoning |

|---|

| PVC Pellets | Single Screw | Efficient processing of uniform pellets |

| PVC Powder | Twin Screw | Better powder handling and heat control |

| PE/PP Pellets | Single Screw | Cost-effective processing of standard resins |

| Heat-Sensitive Materials | Twin Screw | Better temperature control, shorter residence time |

| Filled Compounds | Twin Screw | Superior mixing of fillers and base resin |

| Recycled Materials | Twin Screw | Better handling of variable input materials |

According to industry research, material form is one of the most critical factors in extruder selection. PVC processing provides a clear example of this principle – while PVC pellets process well in single screw extruders, PVC powder typically requires a twin screw setup for optimal results.

For manufacturers working with standard thermoplastic pellets like PE and PP for applications such as our small diameter pipe extrusion lines, single screw extruders often provide the most cost-effective solution with excellent reliability.

What Are the Cost Implications of Single vs Twin Screw Extruders?

Budget constraints often limit equipment choices, and many manufacturers worry about balancing initial investment against long-term operational costs. Making the wrong decision can impact profitability for years.

The cost difference between single and twin screw extruders extends beyond the initial purchase price to include operational expenses, maintenance requirements, and production capabilities that affect your return on investment.

Initial Investment and Operating Costs

The financial aspects of extruder selection include several important considerations:

Purchase Price: Single screw extruders typically cost 30-50% less than comparable twin screw machines. This significant difference in initial investment makes single screw extruders particularly attractive for companies with limited capital budgets or those just entering the plastic processing industry.

Energy Consumption: Single screw extruders generally consume less energy per kilogram of processed material for simple applications. However, for complex mixing operations, twin screw extruders may actually be more energy-efficient despite their higher power requirements, as they can complete processes in fewer steps.

Maintenance Expenses: The simpler design of single screw extruders typically results in lower maintenance costs and fewer replacement parts. Twin screw machines, with their more complex configurations and higher wear rates, often require more frequent maintenance and more expensive replacement components.

A comprehensive cost analysis should consider these factors in the context of your specific production requirements. For many standard applications, the lower initial and ongoing costs of single screw extruders make them the more economical choice.

Production Efficiency and Output Quality

Beyond direct costs, production efficiency significantly impacts your overall economics:

Throughput Rates: For simple extrusion of pre-compounded materials, single screw extruders often provide comparable or better throughput than twin screw machines of similar size. However, for complex formulations or difficult materials, twin screw extruders may offer higher effective production rates.

Scrap Rates and Quality Consistency: Twin screw extruders typically provide more consistent output quality when processing variable input materials, potentially reducing scrap rates. For manufacturers working with recycled materials or requiring precise mixing, this improved consistency can offset higher equipment costs.

Process Flexibility: Twin screw extruders offer greater process flexibility, allowing manufacturers to handle a wider range of materials and products on a single line. This versatility can be valuable for companies with diverse product portfolios or those anticipating future expansion into new materials.

According to industry experts at Fictiv, the return on investment timeline differs significantly between these technologies. Single screw extruders typically offer faster ROI for standard applications, while twin screw systems may provide better long-term returns for specialized or complex processing needs.

How Do Performance and Output Quality Compare Between These Extruder Types?

Product quality inconsistencies can damage your reputation and lead to customer dissatisfaction. Understanding how extruder choice affects output quality is essential for maintaining competitive advantage.

The performance characteristics of single and twin screw extruders directly impact product quality, consistency, and the range of applications you can successfully produce.

Mixing Efficiency and Material Homogeneity

The fundamental difference in mixing capability significantly impacts output quality:

Single Screw Mixing: Single screw extruders provide primarily distributive mixing, which redistributes components that are already well-dispersed. This is adequate for many standard applications using pre-compounded materials but may be insufficient for complex formulations or when incorporating additives.

Twin Screw Mixing: Twin screw extruders excel at both distributive and dispersive mixing. Dispersive mixing breaks down agglomerates and creates fine dispersions of additives, resulting in more homogeneous output. This superior mixing capability is particularly valuable for color mixing, incorporating fillers, or processing materials with additives.

Process Control and Consistency

Consistent processing conditions lead to consistent product quality:

Temperature Control: Twin screw extruders generally offer more precise temperature control due to their self-wiping action and shorter residence times. This makes them advantageous for heat-sensitive materials or applications requiring tight temperature tolerances.

Pressure Stability: Single screw extruders typically generate more stable and higher pressures, which can be beneficial for applications requiring consistent die pressure. This pressure stability contributes to dimensional consistency in products like pipes and profiles.

Output Consistency: For materials with consistent properties, single screw extruders provide excellent output stability. However, when input materials vary in properties (as with recycled materials), twin screw extruders often deliver more consistent results due to their superior mixing and homogenization capabilities.

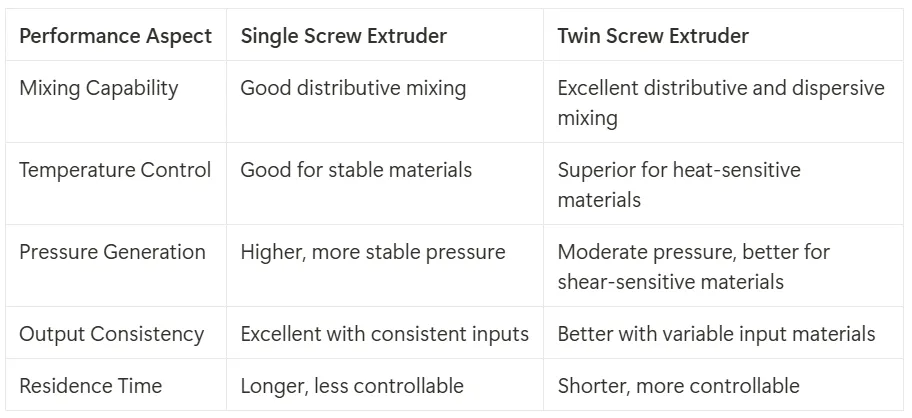

single screw extruder vs twin screw extruder,the main performance aspect between them

single screw extruder vs twin screw extruder,the main performance aspect between them

What Maintenance and Operational Considerations Should I Keep in Mind?

Unexpected downtime and maintenance issues can disrupt production schedules and increase operational costs. Many manufacturers underestimate these factors when selecting equipment.

The maintenance requirements and operational characteristics of extruders have significant implications for long-term ownership costs and production reliability.

Maintenance Requirements and Accessibility

Different extruder designs present varying maintenance challenges:

Screw and Barrel Wear: Single screw extruders typically experience less wear than twin screw machines due to their simpler operation and lower shear forces. This often results in longer intervals between screw and barrel replacements, reducing both maintenance costs and downtime.

Cleaning and Material Changes: Twin screw extruders generally offer advantages for cleaning and material changes due to their self-wiping screw design. This can be particularly valuable for manufacturers who frequently change materials or colors.

Accessibility and Complexity: The simpler design of single screw extruders makes maintenance procedures more straightforward and often requires less specialized knowledge. Twin screw systems, with their more complex configurations, may require more specialized maintenance expertise.

At Jinxin, we design our single screw extruders with maintenance accessibility in mind, incorporating features that facilitate routine maintenance and minimize downtime.

Operational Considerations

Day-to-day operation presents different challenges depending on extruder type:

Startup and Shutdown Procedures: Single screw extruders typically have simpler startup and shutdown procedures, requiring less operator expertise. This can be advantageous for companies with varying operator skill levels or high staff turnover.

Process Adjustment Sensitivity: Twin screw extruders offer more process variables and adjustment possibilities, providing greater flexibility but also requiring more skilled operation. Single screw systems are generally more forgiving of minor process variations.

Training Requirements: The relative simplicity of single screw operation typically translates to shorter operator training periods and less specialized knowledge requirements. This can be particularly beneficial for smaller operations or those in regions with limited access to specialized training.

Conclusion: Making the Right Choice for Your Production Needs

Selecting between single and twin screw extruders requires careful consideration of your specific application requirements, material characteristics, budget constraints, and operational capabilities. There is no universal “best” choice – the optimal technology depends on your unique manufacturing context.

For many standard applications using consistent materials like PVC pellets or PE/PP, single screw extruders offer an excellent balance of performance, reliability, and cost-effectiveness. Their simpler design translates to lower initial investment, easier maintenance, and straightforward operation.

Twin screw extruders provide superior performance for applications requiring intensive mixing, processing of difficult materials like PVC powder, or handling variable input materials. While they typically involve higher initial investment and maintenance costs, their enhanced capabilities may justify these expenses for specialized applications.

At Jinxin Plastic Machinery, we specialize in high-quality single screw extrusion equipment designed for reliability, efficiency, and value. With over a decade of experience in the industry, we can help you evaluate your specific needs and determine the most appropriate extrusion technology for your application. Contact us today to discuss your plastic processing requirements and discover how our expertise can support your manufacturing success.

References:

- Development, Recent Advances, and Updates in Binary, Ternary Co-Amorphous Systems, and Ternary Solid Dispersions – Scientific Figure on ResearchGate. Available from: https://www.researchgate.net/figure/Schematic-of-a-single-screw-and-twin-screw-extruder_fig4_372202890 [accessed 16 Jun, 2024].