Máquina de extrusión de tubos PPR

Línea de extrusión monohusillo de alta velocidad

Para tubos de pequeño diámetro (16-160 mm) y multicapa

Máquina de extrusión de tubos PPR Especificaciones técnicas y selección de modelos

Parámetros básicos de nuestras líneas de extrusión de tubos PPR de la serie SJ. Disponemos de configuraciones personalizadas para un mayor rendimiento bajo pedido. ¿No encuentra su requisito específico? Ofrecemos ingeniería personalizada para necesidades especiales (tubos PP/PE).

Configuración de la máquina | Diámetro del tornillo. | Relación L/D | Alcance del tubo (mm) | Producción máxima (kg/h) | Especificación |

|---|---|---|---|---|---|

JX-SJ65/33 (Doble) | 65 mm | 33:1 | 20-75 (x2) | 200-250 | Doble eficiencia de salida |

JX-SJ65/33 (Individual) | 65 mm | 33:1 | 20-75 | 80-120 | Producción estándar |

JX-SJ75/33 (Individual) | 75 mm | 33:1 | 50-160 | 80-150 | Flexibilidad de gran alcance |

JX-SJ90/33 (Individual) | 90 mm | 33:1 | 75-250 | 280-350 | Gran capacidad para grandes tamaños |

Módulos completos de la línea de fabricación de tubos PPR (unidades principales + complementos opcionales)

Una solución llave en mano desde la tolva hasta el apilador. Construya la línea como un sistema completo, configurado según el rango de diámetro exterior del tubo, PN/SDR, estructura de capas y método de embalaje. A continuación se muestra la lista de módulos típicos utilizados en proyectos de extrusión de tubos PPR.

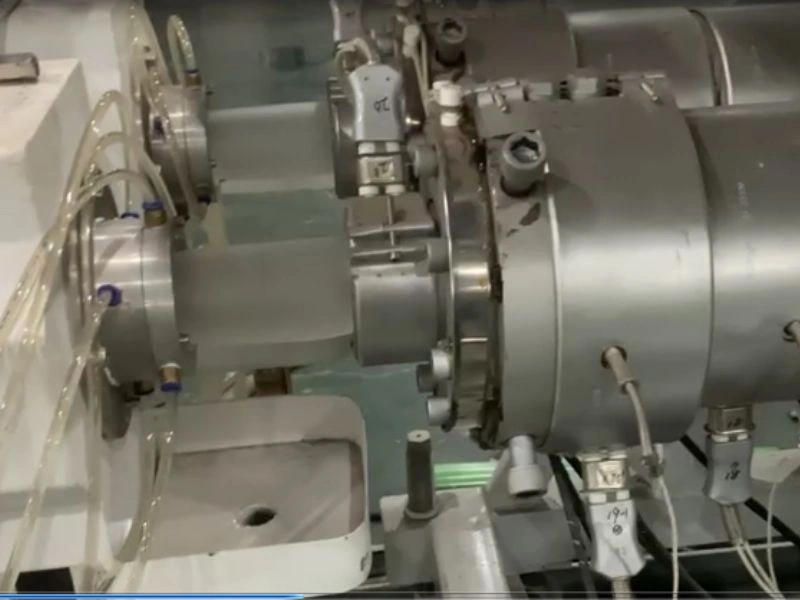

Extrusora monohusillo de alto rendimiento

- Motor: Siemens Beide (Inverter Duty)

- Conduce: Acoplamiento directo (Sin correas, sin mantenimiento)

- Inversor: ABB ACS580 Alto rendimiento

- Control: WECON PLC + Pantalla táctil

- Tornillo: Acero nitrurado (profundidad: 0,8 mm)

- Calefacción: FOTEK Control SSR

- Peso por metro de control

Co-Extrusor auxiliar

- Motor: Siemens Beide

- Conduce: Acoplamiento directo (Energía fiable)

- Inversor: ABB ACS580

- Tornillo: Acero nitrurado (profundidad: 0,8 mm)

- Calefacción: Control FOTEK SSR

- Diseño: Movilidad independiente y ajuste

- Sistema PLC opcional

Tanque de calibración de vacío

- Material: Acero inoxidable SUS304 (Resistente a la corrosión)

- Refrigeración: Sistema de pulverización de alta presión a 360

- Control: Regulación independiente del vacío

- Alineación: 3 ejes ajustables (Centrado preciso)

- Estabilidad: Control automático del nivel de agua

Tipo Caterpillar Haul-Off

- Conduce: 2 motores independientes (superior e inferior)

- Ventaja: Sin pestañas de transmisión, tirón más suave

- Inversor: ABB

- Bloques: Goma resistente al desgaste (no daña las tuberías)

- Control: Sincronización automática a través de la HMI principal (vinculada a la velocidad del alimentador)

Cortadora sin virutas y apiladora de 6 m

- Método: Cortador giratorio (sin rebabas ni rebabas)

- Control: PLC + pantalla táctil (placa de ordenador)

- Precisión: Medición de la longitud del codificador (±1 mm)

- Colección: Apilador de 6 m incluido

- Acción: Volteo neumático (descarga sin arañazos)

Enfriadoras industriales refrigeradas por aire

- Función: Sistema de refrigeración por agua de circuito cerrado

- Ventaja: No se necesita piscina de agua civil

- Instalar: Diseño Plug and Play

- Resultado: Temperatura constante = Tamaño de tubo estable

¿Está listo para configurar su línea de tuberías PPR?

Si tiene preguntas rápidas o desea información general sobre los precios, utilice el botón Contacto rápido Barra lateral a la derecha (o abajo en el móvil).

Sin embargo, para un presupuesto preciso basado en la configuración y plano de distribución en fábrica, le recomendamos que nos facilite sus requisitos específicos.

Dedicados a la extrusión monohusillo desde 2012

Jinxin se centra exclusivamente en la tecnología monohusillo. Este enfoque especializado nos permite perfeccionar la estabilidad de la máquina y la eficiencia de producción al más alto nivel en toda nuestra gama de líneas de extrusión.

Suministramos equipos de calidad empresarial que superan las rigurosas auditorías de grupos internacionales. Tanto si se trata de una empresa emergente como de un gigante del sector, combinamos ingeniería de precisión con valor directo de fábrica, lo que le permite escalar su producción sin concesiones.

Por qué los fabricantes y responsables de compras eligen Jinxin

Proveedor de líderes mundiales

Las extrusoras Jinxin operan dentro de las fábricas de los principales grupos internacionales. Superamos sus rigurosas auditorías de proveedores, aportando a su planta una fiabilidad de nivel empresarial. (Nombres de clientes protegidos por NDA).

Directo de fábrica

Sin intermediarios. Somos propietarios de los códigos fuente del software y de los planos mecánicos, lo que garantiza un soporte de por vida para las actualizaciones.

Certificado CE y asistencia fiscal

Equipos con certificación CE. Si lo solicita, configuramos la línea para que cumpla sus normas de tuberías objetivo (por ejemplo, ISO 15874). También proporcionamos certificados de origen para ayudarle a minimizar sus aranceles de importación.

Obtenga su presupuesto basado en la configuración

Proporcione a continuación los objetivos de su máquina de extrusión de tubos PPR. Nuestros ingenieros diseñarán la disposición (P&ID) y calcularán el precio fábrica-directo exacto para usted.