Vinyl Tube Extruder Machine Line

Set up your own factory with our PVC/TPU Extrusion Equipment

What is a vinyl tube extruder Machine?

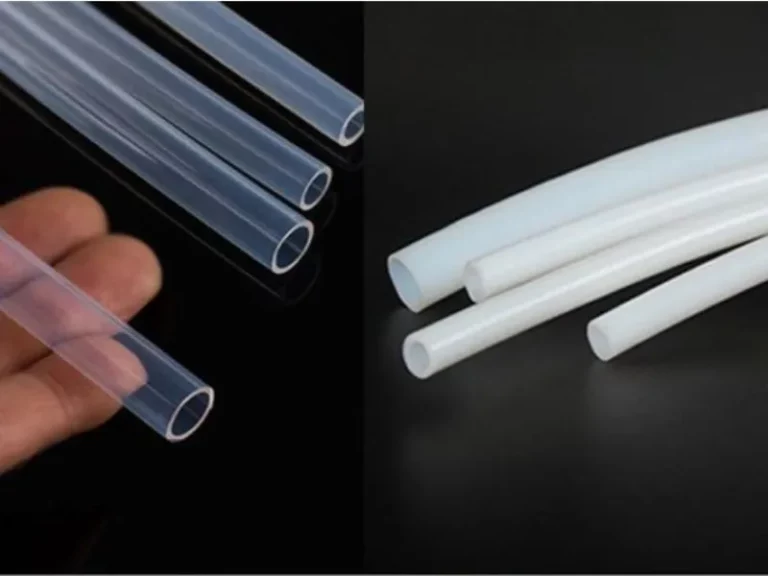

Industry-leading vinyl tube extruders are designed for stability, precision, and exceptional value. Our production equipment engineered explicitly for manufacturing single-chamber tubes from PVC or TPU materials.

These versatile tubes find applications across diverse sectors, including medical, industrial, and more, providing reliable solutions for various needs.

With precision capabilities reaching as low as 1.6mm in diameter

Key Features of Our TPE Extrusion Machines

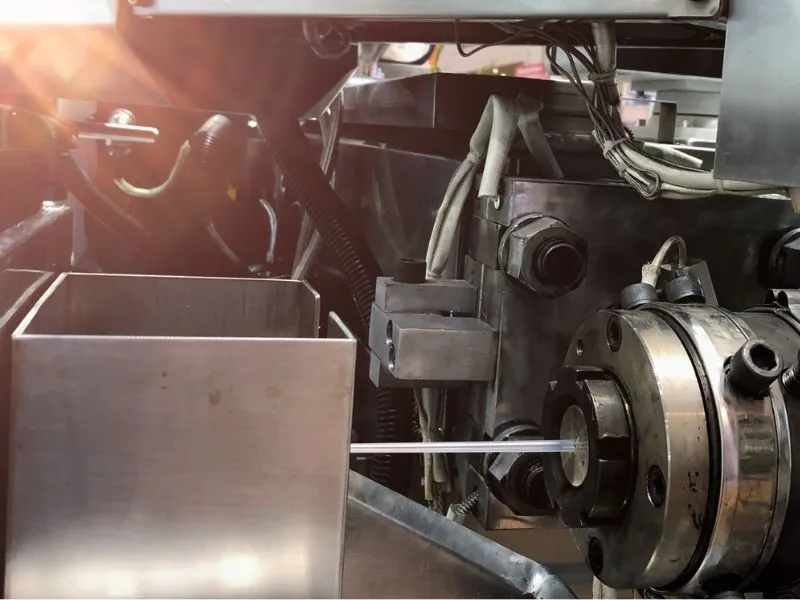

Main Extruder

The main extruder in our PVC tubing extrusion line is a single screw extruder designed for processing PVC granulated material.

This extruder is engineered to ensure consistent melt quality and optimal material flow, which is crucial for producing high-quality PVC tubing.

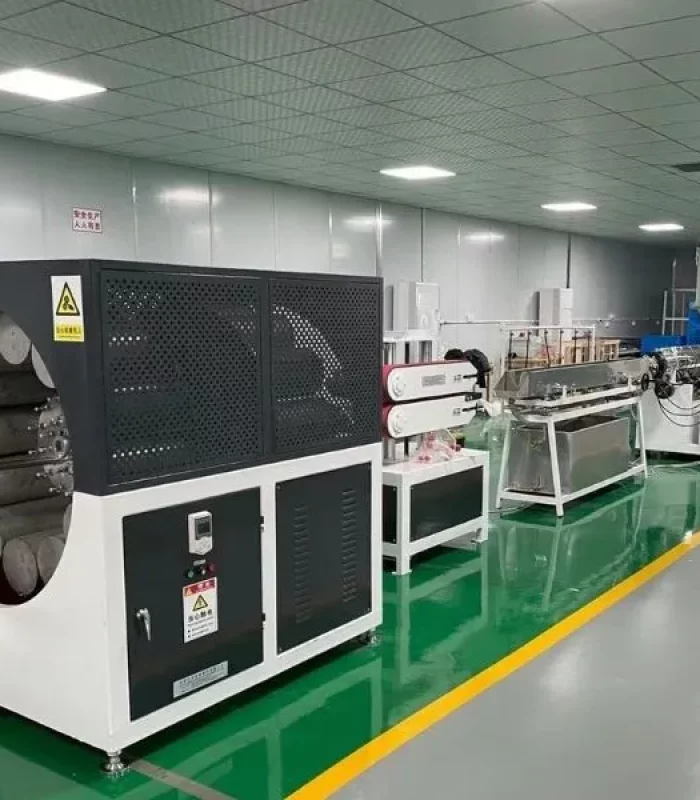

Water Cooling Tank

After extrusion, the hot PVC tubing is passed through a water cooling tank. This stage is critical for solidifying the tubing and maintaining its dimensional accuracy.

Combined Haul-Off and Servo Cutter

Our extrusion line includes a combined haul-off and servo cutter mounted on the same platform.

This integrated system ensures the tubing is pulled through the line at a consistent speed and cut to precise lengths without generating debris.

Pain Points and Solutions Before Making Purchasing Decision

As a potential buyer from another country looking to invest in high-value extrusion equipment, we understand the challenges and uncertainties you might face. Here, we address common concerns to help you feel more confident about your decision.

High Investment, No Physical Samples

Extrusion equipment is a significant investment, and without physical samples, it can be hard to trust online information.

Solutions

We provide detailed videos showcasing our equipment in operation, along with customer testimonials and case studies. This gives you a clear view of the machine's performance and reliability.

Lack of On-Site Demonstrations

Our equipment is highly customized, and it's challenging to see a fully operational machine in our factory due to the specific nature of each order.

Solutions

If you visit China, we can arrange for you to see our machines in action at our customer's factories, provided the purchasing process is nearing completion.

Trust and Credibility Issues

Trusting an overseas supplier for such a large purchase can be daunting, especially when you can't physically inspect the machinery.

Solutions

You can witness the test runs of your specific equipment at our factory before shipping. Alternatively, we can provide detailed video documentation of the test runs. We can also connect you with existing clients in your country for direct feedback.

Samples Of Finished Products On The Extrusion Line

Why Choose Our Extrusion Machine

Expertise you can trust

When selecting equipment for your new project, it’s crucial to address the key pain points of quality, cost efficiency, reliability, and trusted expertise. Here’s why our equipment stands out as the best choice to meet these needs:

Proven Quality

Over a decade of experience and customer feedback ensures our selected machines offer long-term durability and reliable performance.

Exceptional Value

We provide high-quality equipment at competitive prices, maximizing your investment with top-tier performance.

Reliable Support

Comprehensive support and service ensure smooth operation and minimal downtime, maintaining optimal productivity.

About JINXIN Plastic Machinery

Since 2012

We are honest and reliable, providing cost-effective equipment for your factory

By choosing our equipment, you are partnering with a supplier dedicated to resolving your pain points with expertly curated, high-quality, and cost-effective solutions. We stand by the reliability and performance of every product we offer, ensuring that your investment delivers the results you need for your business to thrive.

Our Customers Say

Our amazing Suppliers

Extrusion Machine Related Q&A

May help you know more

What are the key advantages of using a single screw extruder for PVC soft hose production?

The single screw extruder is highly efficient for PVC soft hose production due to its ability to consistently melt and mix PVC granules, ensuring uniform material quality.

It offers precise temperature control, which is crucial for processing PVC materials and producing hoses with consistent wall thickness and strength.

Additionally, single screw extruders are cost-effective and easy to maintain, making them a preferred choice for many manufacturers.

How does the water cooling tank impact the quality of the extruded PVC soft hose?

The water cooling tank plays a critical role in stabilizing the extruded PVC hose by cooling it uniformly. This process prevents deformation and ensures the hose retains its intended dimensions and flexibility.

The cooling tank’s adjustable water flow allows for precise control over the cooling rate, which is essential for maintaining the hose’s physical properties and ensuring high-quality output.

What benefits does the integrated haul-off and servo cutter system provide in the PVC soft hose extrusion line?

The integrated haul-off and servo cutter system ensures that the extruded PVC hose is pulled through the production line at a consistent speed and cut to precise lengths without producing debris.

This system enhances production efficiency and accuracy, resulting in clean, burr-free cuts that meet specific length requirements.

The synchronization between the haul-off machine and the servo cutter minimizes material waste and reduces the need for manual adjustments, improving overall production reliability and quality.