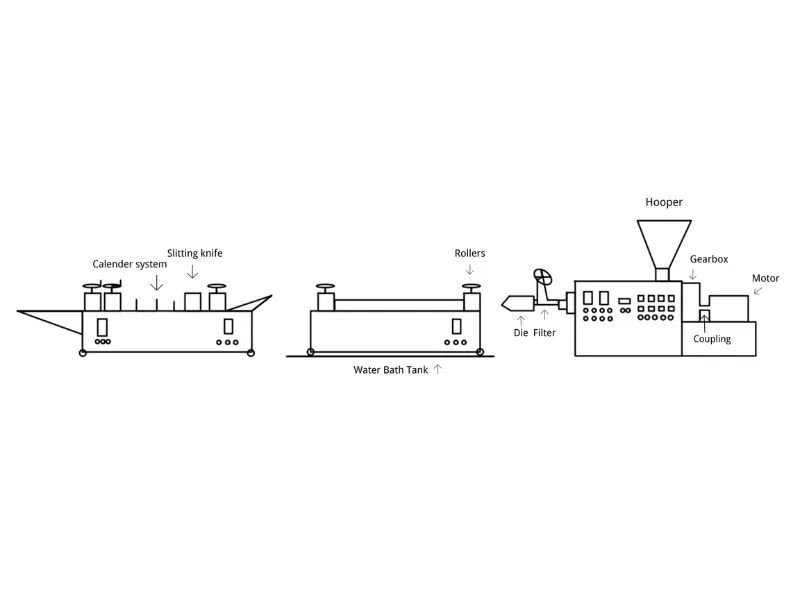

TPE Band Extrusion Equipment for Medical and Fitness Applications

Your Complete TPE Elastic Band Production Line

Our TPE band extrusion equipment delivers elastic bands for medical tourniquets, Esmark bands, and fitness resistance bands. With years of expertise, we provide reliable machines and tested TPE raw materials to help you produce high-quality, profitable products.

Are you seeking for realiable raw material supplier? Check out our Raw Material section for detailed insights and expert information tailored to your needs.

Key Features of TPE Band Extrusion Equipment

Main Extruder

Main Extruder is designed to handle the unique properties of thermoplastic elastomers, ensuring high-quality and precise production of elastic bands. The main extruder utilize advanced technology to melt and shape TPE materials, producing elastic bands that meet stringent industry standards.

Rollers and Cooling Water Tank

This section of the machine line comprises a set of rollers and a water-cooled shaping trough.

The rollers control the product’s thickness, width, and surface texture, creating either a smooth or textured surface. After passing through the rollers, the product enters the water trough for cooling and shaping. It is then conveyed to the cutting machine via traction.

Forming haul-offs and cutting machine

This section focuses on traction and cutting. In response to the primary need for tourniquet manufacturing, we have developed a spot-connection cutting machine. This innovation ensures that the tourniquets are not entirely cut during the process, allowing them to be easily separated by hand when needed.

The blade placement is customized according to the customer’s product specifications.

REQUEST A quote

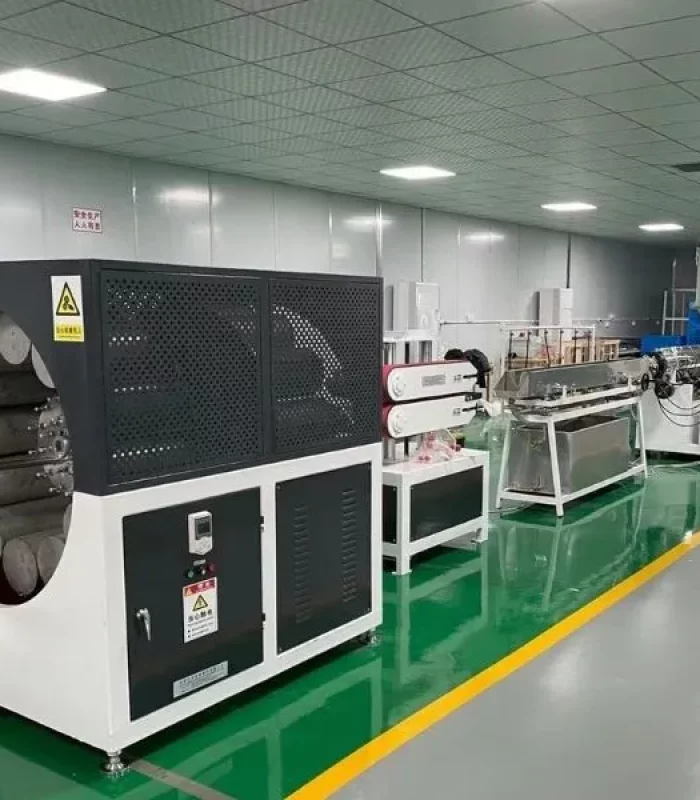

Want to Know More? Discover Our Full Production Line Below

TPE Band Extrusion Equipment Q&A

May help you know more

How do I choose the right TPE for band production?

The right TPE affects elasticity, durability, and safety in products like tourniquets. We supply tested TPE raw materials and guide you to the best formulation for your needs.

Why do TPE raw materials have such a significant impact on production?

Based on feedback from our clients, if your raw materials contain excessive oily substances, the extruded product may have shiny spots and a sticky feel, leading to adhesion. In these instances, you would need to consult your raw material supplier to adjust the formula.

Can it make bands in different sizes?

Absolutely. Our latex-free TPE band extrusion lines adapt to produce various widths and profiles for your specific applications.

Why Choose Our Extrusion Machine

Expertise you can trust

When selecting equipment for your new project, it’s crucial to address the key pain points of quality, cost efficiency, reliability, and trusted expertise. Here’s why our equipment stands out as the best choice to meet these needs:

Proven Quality

Over a decade of experience and customer feedback ensures our selected machines offer long-term durability and reliable performance.

Exceptional Value

We provide high-quality equipment at competitive prices, maximizing your investment with top-tier performance.

Reliable Support

Comprehensive support and service ensure smooth operation and minimal downtime, maintaining optimal productivity.

About JINXIN Plastic Machinery

Since 2012

We are honest and reliable, providing cost-effective equipment for your factory

By choosing our equipment, you are partnering with a supplier dedicated to resolving your pain points with expertly curated, high-quality, and cost-effective solutions. We stand by the reliability and performance of every product we offer, ensuring that your investment delivers the results you need for your business to thrive.

Our Customers Say

Our amazing Suppliers

EXTRUSION SOLUTIONS

Email Address

sales@jfextruder.com

Factory Address

No. 31 Yuci Rd., Yuyao, Ningbo City, Zhejiang Province, China