Multi-color Smooth Shower Hose Extrusion Line

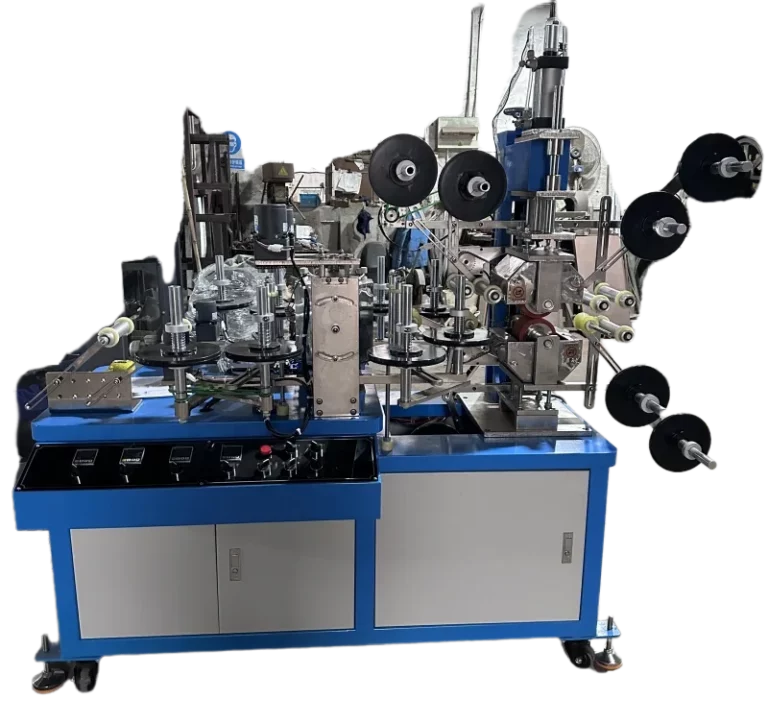

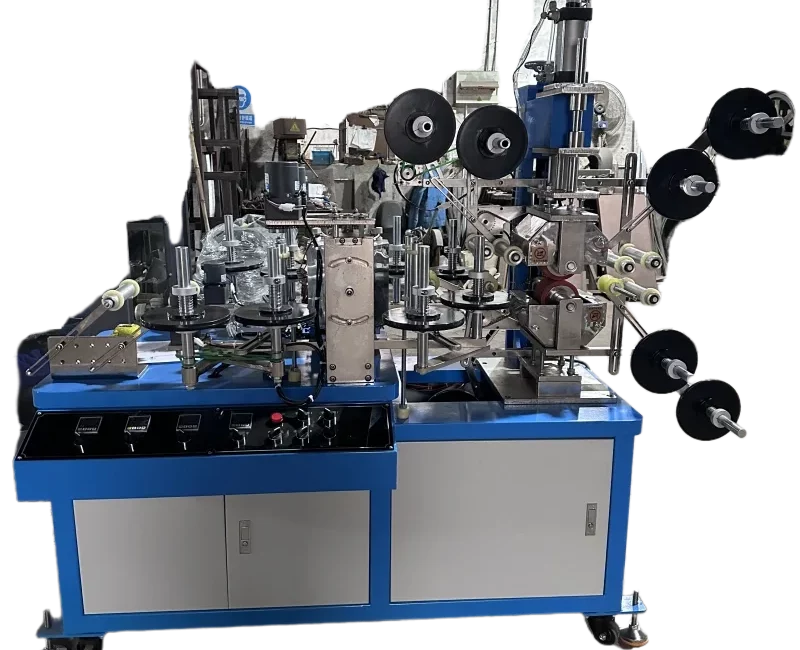

Film-Coated Machine: Precision Color Coating for Shower Hoses

Key Features:

- Multi-Directional Coating: Applies film from four angles for a flawless, seamless finish.

- Vivid and Durable Colors: Heat-melted silver film ensures lasting vibrancy and toughness.

- Smooth Surface: Achieves a flat, polished exterior that enhances both look and feel.

- High Efficiency: Simultaneous application streamlines production while maintaining quality.

With the Film-Coated Machine, you can produce shower hoses that combine striking aesthetics with reliable performance, setting your products apart in a competitive market.

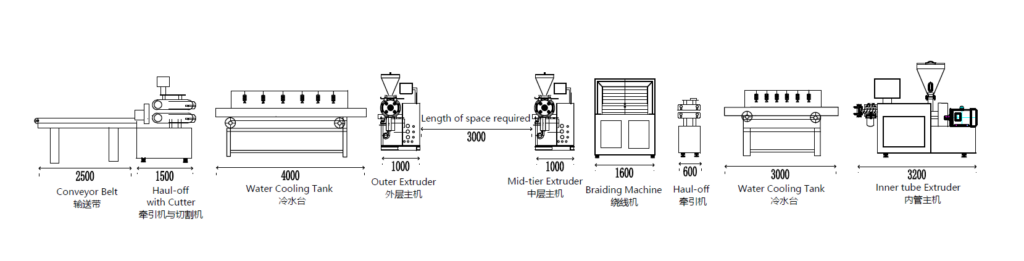

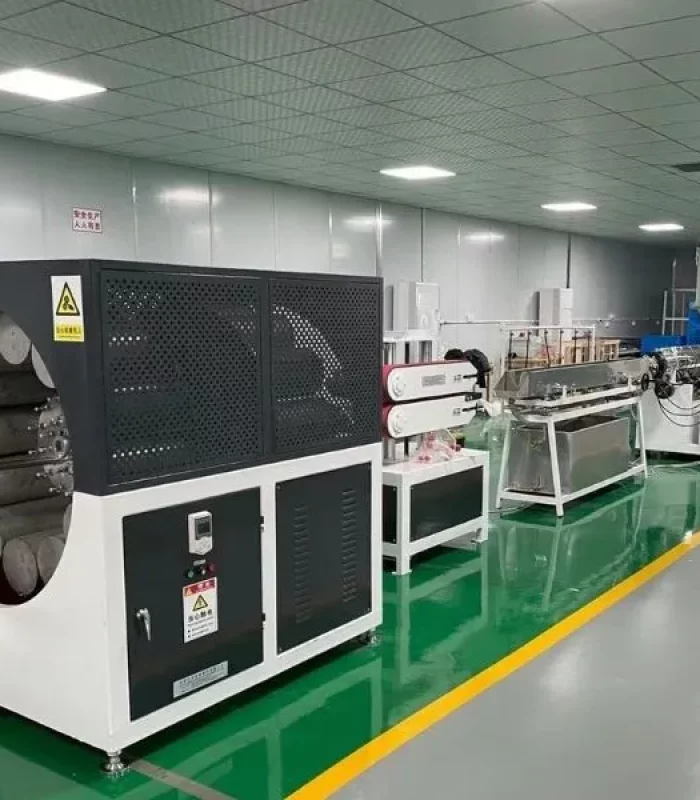

Machine Layout of Our Multi-color Smooth Shower Hose Extrusion Line

Our glossy colored PVC shower hose extrusion line is specifically designed to create high-quality, aesthetically appealing hoses with a smooth, colored exterior.

The line utilizes dual main extruders for co-extrusion, enabling the simultaneous production of the hose’s inner and outer layers. The water cooling tank ensures the hoses maintain their shape and stability. The integrated haul-off equipment and servo cutter provide precise control and clean cuts.

Unique to our system is the outer layer coloring device, which can apply either a matte or glossy finish. The glossy finish, particularly in bright silver, has become increasingly popular, offering a sleek and luxurious look.

Importantly, all our coloring inks are tested to be safe for human contact and meet stringent EU standards.

Difference Between Matte and Glossy Colors

REQUEST A quote

Want to Know More? Discover Our Full Production Line Below

Key Components of Our Multi-color Smooth Shower Hose Extrusion Line

Our smooth shower hose extrusion line is composed of several critical components that work together to produce high-quality, multi-color shower hoses. Each part is designed for precision and efficiency.

Precision Single-Screw Extruder

Ensures consistent material flow for uniform hose thickness.

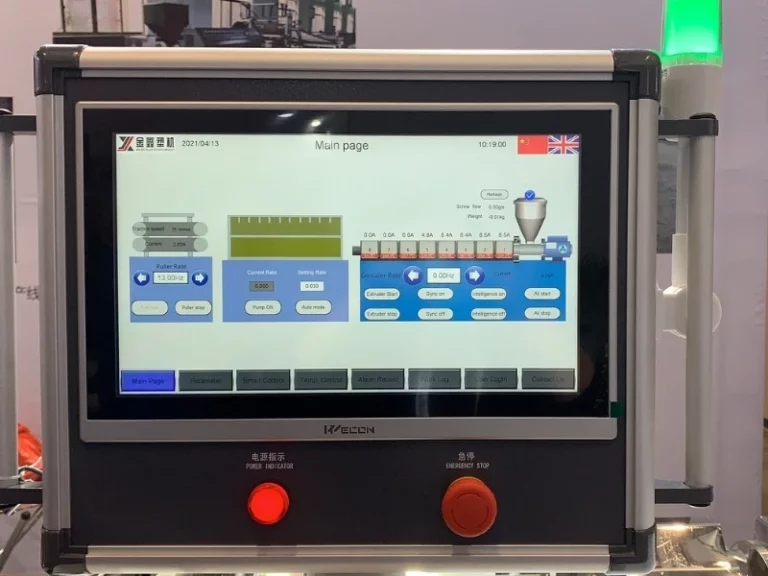

Temperature Control: Equipped with state-of-the-art PLC control systems and touch screen interfaces, our machines ensure precise control over the extrusion process, guaranteeing superior quality in every production run.

Efficient Cooling System

Cools the extruded hose rapidly to lock in shape and quality. Additional cooling tanks can be added if multiple extruders or higher output is required.

Quickly sets the hose shape, maintaining quality and speeding up production.

Haul-Off Unit

Reliable Haul-Off Mechanism-Maintains consistent tension and precise dimensions during production, ensuring the hose meets your quality standards.

Maintains consistent tension for accurate dimensions.

Braiding Machine

Key part of our PVC Braided Reinforced Hose Extrusion Line. It weaves a layer of fiber or metal wire around the inner PVC tube, greatly improving the hose’s strength, pressure resistance, and durability.

It offers high-speed operation, customizable settings, and precise control for consistent quality and efficient production.

Film-coated Machine

The Film-Coated Machine coats shower hoses with a seamless, durable color layer using silver film and heat-melting.

It creates a smooth, polished finish that hides the reinforcement layer.

This technology ensures lasting vibrancy and wear resistance.

Flexible Finishing Options

The finished hose can be cut to custom lengths or wound into rolls depending on your packaging and delivery requirements.

Multi-color Smooth Shower Hose Extrusion Line Q&A

May help you know more

What colors are available for the shower hoses?

Our extrusion line supports a wide range of colors, including matte and glossy finishes, to match any design preference

Does the color coating affect the durability of the hose?

The color coating is designed to be durable and resistant to wear, ensuring the hose maintains its appearance and functionality over time.

Can the shower hoses be customized with additional patterns or features?

Yes, our Multi-color Smooth Shower Hose Extrusion Line supports a wide range of styles and custom designs.

We can add patterns like logos or unique designs directly onto the hoses. Plus, we offer innovative features like temperature-sensitive color-changing films that shift colors based on water temperature.

All of these options can be fully customized to match your specific requirements.

About JINXIN Plastic Machinery

Since 2012

We are honest and reliable, providing cost-effective equipment for your factory

By choosing our equipment, you are partnering with a supplier dedicated to resolving your pain points with expertly curated, high-quality, and cost-effective solutions. We stand by the reliability and performance of every product we offer, ensuring that your investment delivers the results you need for your business to thrive.

Proven Quality

Over a decade of experience and customer feedback ensures our selected machines offer long-term durability and reliable performance.

Exceptional Value

We provide high-quality equipment at competitive prices, maximizing your investment with top-tier performance.

Reliable Support

Comprehensive support and service ensure smooth operation and minimal downtime, maintaining optimal productivity.

Our Customers Say

Our amazing Suppliers

EXTRUSION SOLUTIONS

Email Address

sales@jfextruder.com

Factory Address

No. 31 Yuci Rd., Yuyao, Ningbo City, Zhejiang Province, China