What is Plastic Extrusion? The Process Explained (From Melting to Cooling)

Plastic extrusion is a continuous manufacturing process used to produce high-volume products such as pipes, tubes, profiles, sheet, film, and coated wire/cable. In simple terms, plastic is melted, pushed through a shaped die, and cooled into a consistent cross-section.

If you’re researching extrusion for the first time—especially from a sourcing or procurement angle—the real question is usually consistency: Can the process hold dimensions and surface quality over long runs without constant adjustments?

This guide explains what is plastic extrusion, how the process works step-by-step, and what variables typically matter when evaluating feasibility.

Quick Summary

Definition: Plastic extrusion is a continuous process that melts thermoplastic material and forces it through a die to create a continuous profile with a consistent cross-section.

Common outputs: Pipe, tube, profile, sheet/film, cable jacketing, and other continuous industrial shapes.

What drives stability: In practice, consistency is influenced by melt temperature history, pressure behavior, cooling consistency, and line speed synchronization.

Why buyers care: Better stability typically means lower scrap, more repeatable dimensions, and a smoother production ramp-up.

What is Plastic Extrusion?

Plastic extrusion is a manufacturing process that converts thermoplastic resin (usually pellets, sometimes powder or blends) into a continuous product by melting it in an extruder and pushing the melt through a shaped die. The extrudate is then cooled, pulled at a controlled speed, and cut or wound into finished form.

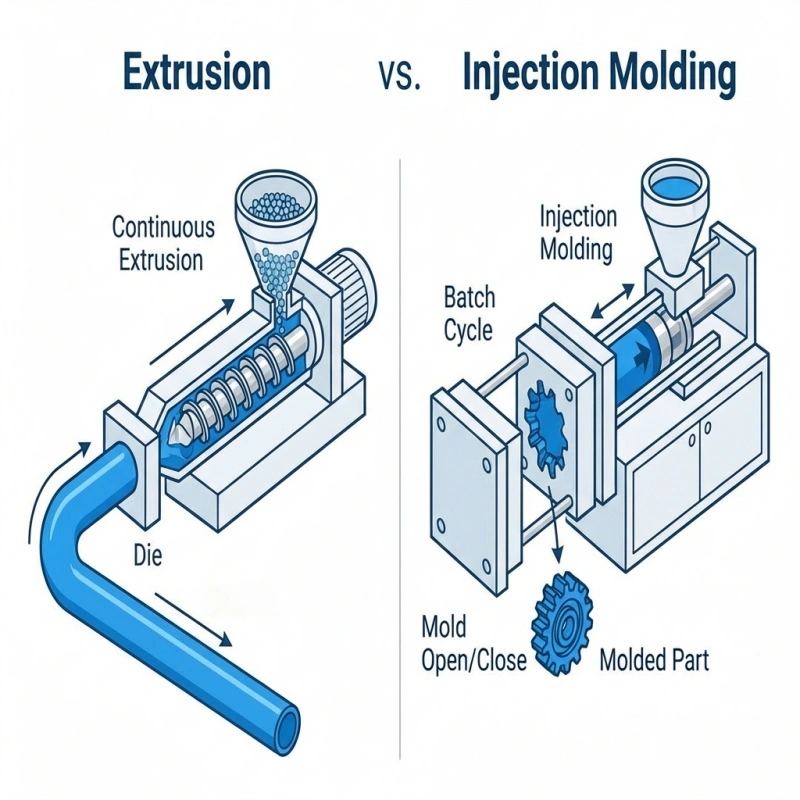

Extrusion vs. Injection Molding (quick difference)

Extrusion: Continuous output for products with a constant cross-section (pipes, tubes, profiles, sheet/film).

Injection molding: Cyclic output for discrete 3D parts (caps, housings, complex components).

Understanding the fundamental differences between extrusion and injection molding helps in selecting the right process for your manufacturing needs:

| Feature | Plastic Extrusion | Injection Molding |

|---|---|---|

| Process Type | Continuous | Batch |

| Product Shape | Uniform cross-section (2D) | Complex 3D shapes |

| Production Volume | High-volume, continuous runs | Individual parts in batches |

| Tooling Costs | Lower die costs | Higher mold costs |

| Material Waste | Minimal waste | Runners and gates create waste |

| Typical Products | Pipes, profiles, sheets, films | Containers, parts, housings |

| Precision Control | Critical for dimensional stability | Critical for part detail |

How the Plastic Extrusion Process Works (Step-by-Step)

Note: This section focuses on plastic extrusion as a process—what happens to the material during melting, die shaping, and cooling. A “plastic extrusion line” is the equipment setup (extruder, die, cooling/sizing, haul-off, cutting/winding). If you’re comparing line configurations or footprint, that’s best covered in a separate extrusion line guide – “What is plastic extrusion line”.

Step 1 — Feeding (stable input sets the baseline)

The process starts at the hopper. Material is introduced into the extruder, and the goal is steady, repeatable feeding. When feeding is inconsistent (for example, bridging, contamination, or poor material handling), the rest of the process often becomes harder to stabilize.

From a buyer’s perspective, this can show up as: unstable output, frequent adjustments, and more startup scrap—even if the extruder itself is capable.

Step 2 — Melting & conveying (making a uniform melt)

Inside the barrel, a rotating screw conveys the material forward while heating and mixing it. Melting occurs through a combination of barrel heating and mechanical energy generated as the screw rotates (shear). In practice, the goal is not only “fully melted,” but uniform enough (temperature and mixing consistency) to reduce downstream variation.

A useful mental model is that the screw is doing several jobs at once: transporting solids, melting, mixing, and building pressure. If any of these functions becomes unstable, it often shows up later as surface defects or dimensional drift.

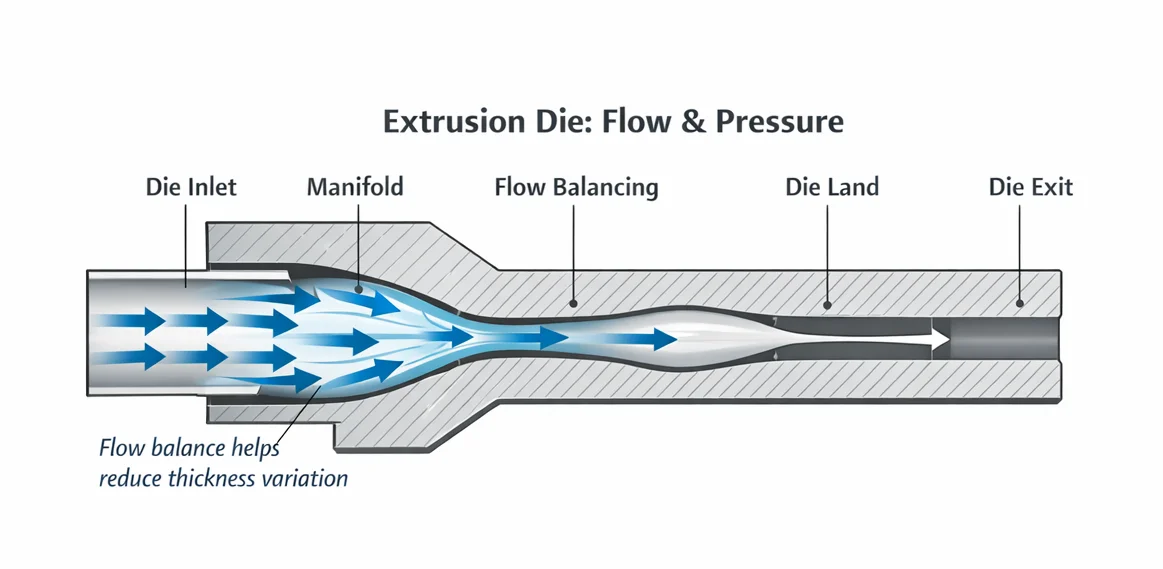

Step 3 — Die shaping (Flow & Pressure)

The die is the bridge between the machine and the product. In practice, it does two jobs:

- Shaping: It transforms the melt from the extruder bore into the target cross-section (e.g., a pipe annulus, profile, or sheet).

- Flow resistance (head pressure): By restricting flow, the die creates resistance that helps stabilize melt delivery and supports more consistent melting/mixing upstream—together with proper screw design and temperature control.

A well-designed die also helps straighten and balance the flow so the melt exits evenly across the cross-section. When flow balance is poor, you may see flow lines, uneven thickness, or unstable output.

Note: The shape exiting the die is only the starting point. Final dimensions are set in the next steps.

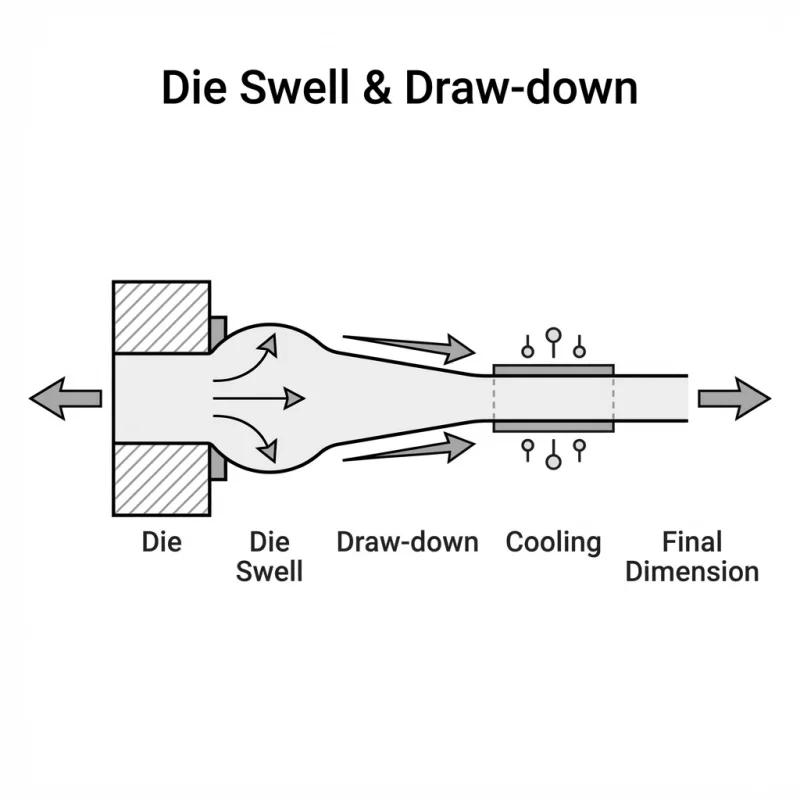

Step 4 — Die Swell & Draw-down (Why the die is rarely a 1:1 match)

Even with a well-made die, the extrudate rarely keeps the exact die-exit shape. Several effects act in different directions:

- Die swell (expansion): Polymer melts can relax and expand after leaving the high-pressure die.

- Draw-down (contraction): In many products, the haul-off pulls faster than the melt exits the die, stretching the profile thinner/smaller.

- Thermal shrinkage: As the product cools, it typically shrinks further, depending on resin and cooling conditions.

Because of these combined effects, die tooling is often designed with compensation so the cooled product lands in the target dimension.

Practical takeaway: The die sets the cross-section concept, but final dimensions are commonly tuned through haul-off speed and cooling consistency, while monitoring dimensional checks and process trends.

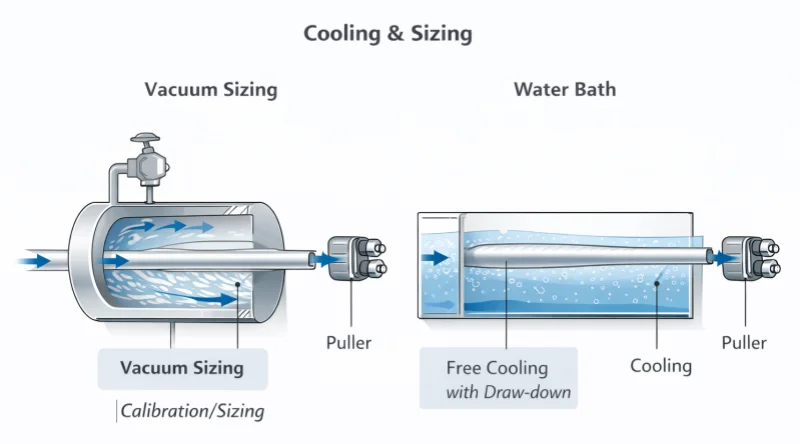

Step 5 — Cooling & sizing (locking dimensions)

Cooling is where the shape becomes “real.” Depending on product type and rigidity, cooling may involve water bath cooling, air cooling, and/or calibration and sizing tools. For many rigid tubes and pipes, vacuum sizing/calibration is commonly used to help control outer diameter and roundness. For other products, free cooling with controlled draw-down can be sufficient.

Cooling consistency matters because uneven cooling can contribute to ovality, warpage, or internal stress—especially when line speed changes or water temperature/flow is unstable.

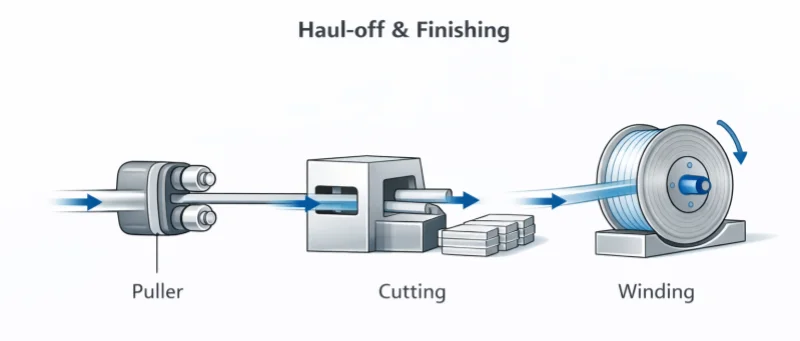

Step 6 — Haul-off & finishing (synchronizing the line)

The haul-off (puller) sets the line speed and influences draw-down. Cutting or winding turns continuous output into sellable lengths or rolls. When haul-off speed and melt delivery are not well synchronized, you may see wall-thickness drift, unstable OD, or inconsistent surface appearance.

From a buyer’s perspective, this is where “the whole process” matters: extrusion output, cooling performance, and pulling stability all interact.

The Core Variables That Typically Control Stability

1) Melt temperature history (not just heater setpoints)

Melt temperature is more than barrel setpoints. In practice, melt temperature can shift with screw speed, load, backpressure, and material behavior. When melt temperature history changes, it can influence flow consistency, surface appearance, and dimensional repeatability.

2) Pressure behavior (a practical indicator many operators watch)

Many teams track melt/die pressure trends as a practical indicator of stability—especially when diagnosing surging or output drift. Pressure behavior is often discussed in extrusion troubleshooting because it can correlate with changes in output consistency.

3) Line speed synchronization (output vs puller speed)

Extrusion is continuous, but it is not “set and forget.” If puller speed changes without the melt supply and cooling keeping up, the product can stretch, thicken, or drift. Over long runs, small speed instability can accumulate into measurable variation.

Common Plastic Extrusion Problems (Process View)

Quick troubleshooting table

| Defect | What you see | Likely process drivers | Practical checks (first pass) |

|---|---|---|---|

| Surging / thickness drift | cyclic OD/wall variation | inconsistent feeding, unstable pressure behavior, melt inconsistency | check hopper/feeding stability; review pressure trend; stabilize melt conditions |

| Rough surface (sharkskin/melt fracture) | rough or matte texture | high shear at die exit, temperature imbalance | reduce shear (RPM); verify die temperature balance; check die land condition |

| Ovality (tubes/pipes) | product not round | uneven cooling/sizing conditions | balance cooling water; verify sizing conditions (if used); check downstream alignment/support |

| Bubbles/voids | pinholes/voids inside wall | moisture/air/contamination (material-dependent) | verify material handling/drying strategy; check for air entrainment |

| Discoloration / burn specks | black dots, yellowing | degradation, dead spots, contamination | reduce residence time; clean die; check for stagnant zones and contamination sources |

A brief precision example

Some applications are less forgiving: small fluctuations can become visible scrap. One example is PS-based transparent tube preforms used in certain lab consumable production, where appearance and consistency can be sensitive to unstable melt conditions and line speed drift.

This example is included only to illustrate a general principle: when consistency requirements tighten, teams typically rely more on stable melt conditions, disciplined line synchronization, and repeatable cooling—regardless of resin category.

If You’re Sourcing an Extruder (what to prepare before requesting quotes)

Procurement teams usually get faster and more comparable quotations when they prepare:

- A product drawing or sample (what dimensions and features matter most)

- Resin basics (pellet/powder/blend; fillers/plasticizers/masterbatch; regrind ratio)

- Output target (kg/h or m/min) and expected operating hours

- Quality priorities (dimension repeatability, surface finish, ovality limits, scrap tolerance)

- Downstream preferences (cooling approach, puller type, cutting vs winding)

For a structured RFQ workflow, you can submit these details using the form on our Контакты page.

Conclusion

What is plastic extrusion in real production terms? It’s a continuous process where stability usually determines profitability: stable feeding, uniform melting, predictable pressure behavior, consistent cooling, and synchronized haul-off.

If you’re comparing suppliers or systems, it helps to evaluate how each approach supports stable runs—not only peak output.

Further Reading

For readers who want to go deeper into extrusion process control and tooling selection:

PTOnline: Use Pressure Control to Minimize Process Variations in Single-Screw Extrusion.

PTOnline: How to Select the Right Tooling for Pipe Extrusion

Explore Topics

Filter by Specs

Have Technical Questions?

Our engineering team is ready to help with your extrusion process or machine configuration.

Jason Shen

Jason is the founder of Jinxin Extruder and a veteran engineer with over 20 years of hands-on experience in plastic machinery.

Starting his career on the shop floor, he mastered every technical detail—from electrical wiring to complex troubleshooting.

Today, he personally oversees final inspections, ensuring every machine is built with deep technical expertise and field-tested reliability.