Reliable Extruder Spare Parts & Maintenance Assurance for Long-Term Operation

Extruder spare parts availability and practical extruder maintenance are critical to long-term production stability. We provide global component chain security and low-maintenance infrastructure exclusively integrated for Jinxin Extrusion Line owners.

Service Policy Notice

Designed to reduce downtime risk after delivery — from spare parts preparation to practical maintenance support.

The extruder spare parts supply services outlined below are strictly reserved for clients operating Jinxin Machinery.

Service Coverage Snapshot

Service scope and included items may vary by extrusion line configuration and are confirmed in the final quotation.

Extruder Spare Parts Coverage Included with Jinxin Extrusion Lines

To reduce early downtime risk after delivery, Jinxin Extruder includes a practical wear spare parts package with each extrusion line. These items are standard wear components—consumables by nature—provided to support stable start-up and routine extruder maintenance, not because of quality concerns.

Included Wear Parts Kit (Typical Reference Items)

Why These Spare Parts Are Included.

These wear parts are selected based on long-term operating feedback and replacement frequency.

Including them helps avoid unnecessary waiting time for common consumables during initial operation and routine extruder heater band replacement or electrical servicing.

Important Scope Clarification

Please note: This kit covers consumable wear parts. It is separate from our standard Machine Warranty, which covers manufacturing defects in core components (Gearbox, Screw, Motor) for 12 months.

Engineered for Low Extruder Maintenance

Effective extruder maintenance is not about adding more procedures—it is about reducing what needs to be serviced and shortening replacement time when wear parts reach the end of their lifecycle.

Our maintenance logic focuses on practical design decisions rather than complex service systems.

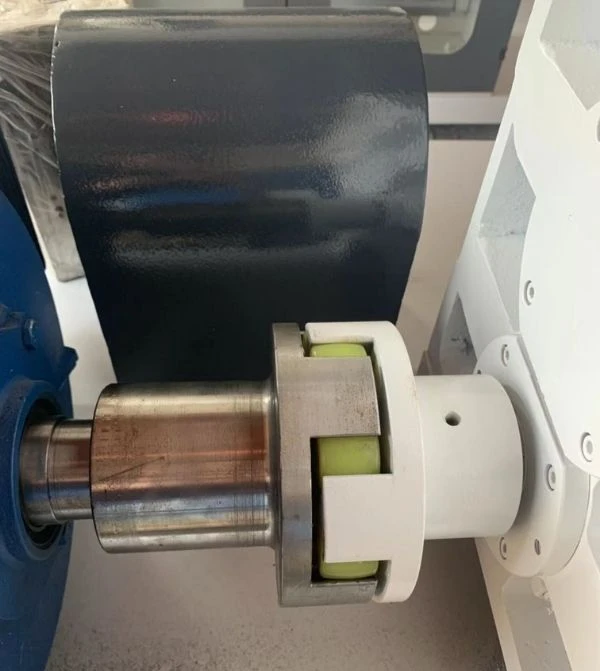

Direct Coupling Drive (Reduced Routine Extruder Maintenance)

Jinxin extrusion lines use direct coupling between the motor and gearbox instead of belt-driven transmission.

This eliminates belt tensioning, belt replacement, and slippage-related issues, reducing routine extruder maintenance workload and improving long-term operational stability.

Service-Friendly Access for Common Wear Parts

Common wear components—including heater bands, solid state relays, thermocouples, and cooling fans—are positioned for direct access.

In typical service scenarios, these items can be replaced without dismantling major assemblies, helping reduce downtime during routine maintenance.

Modular Heating Zones (Targeted Replacement)

Heating systems are designed in independent zones. When a heater band failure occurs, only the affected zone requires replacement.

This targeted approach simplifies extruder heater band replacement and avoids unnecessary disturbance to surrounding components.

Genuine Components & Warranty-Ready Support

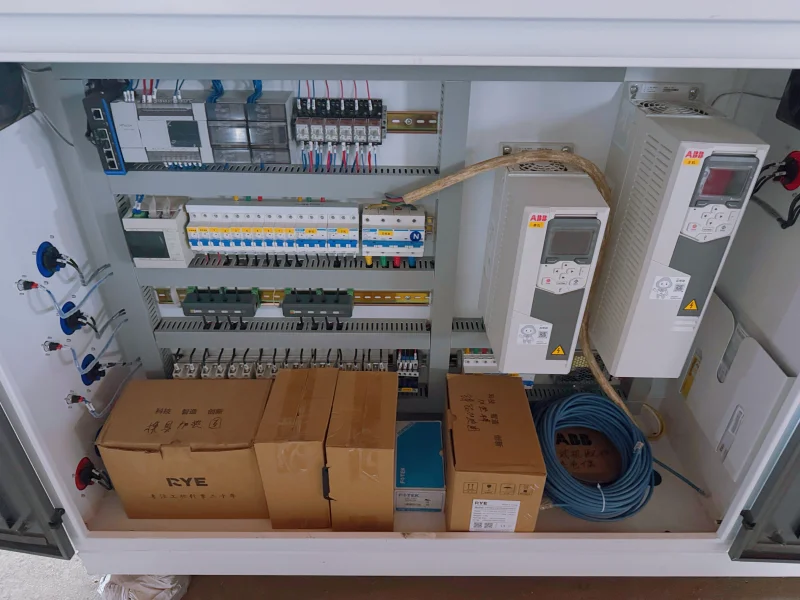

Reliable extruder maintenance depends on component selection. Jinxin extrusion lines are built using genuine, widely adopted electrical components to avoid proprietary lock-in and simplify sourcing, replacement, and warranty handling throughout the machine lifecycle.

Internationally Recognized Components

For core control and automation functions, we integrate components from internationally recognized brands such as Siemens, ABB, OMRON, and RKC, depending on project configuration.

- Standardized specifications widely used in industrial automation

- Easier local sourcing and clearer warranty procedures in many regions

- Reduced risk of long-term spare parts discontinuity

Export-Proven Chinese Brands

For selected electrical and control components, we may use export-proven Chinese brands such as WECON or CHINT when aligned with application requirements and regional support conditions.

- Established export history and overseas distribution presence

- Faster replacement cycles for standard components

- Balanced cost and long-term serviceability