Absorção de humidade

O PA12 é conhecido pela sua baixa absorção de humidade, mas qualquer humidade presente na matéria-prima pode levar a problemas como bolhas e defeitos de superfície na tubagem extrudida.

Soluções

Pré-secar bem os granulados de PA12 antes da extrusão. Utilizar um secador desumidificador para garantir que o material está livre de humidade, evitando defeitos causados pela absorção de humidade.

Defeitos de superfície (pele de tubarão, fratura por fusão)

Os defeitos de superfície, como a pele de tubarão e a fratura por fusão, podem ocorrer devido às elevadas taxas de cisalhamento durante a extrusão, resultando em superfícies de tubagem rugosas ou irregulares.

Soluções

Ajustar os parâmetros de extrusão, reduzindo a taxa de cisalhamento e a velocidade da extrusora. Assegurar definições de temperatura adequadas para reduzir a viscosidade da massa fundida e melhorar o acabamento da superfície.

Estabilidade dimensional

Um arrefecimento inconsistente pode levar a variações nas dimensões da tubagem, afectando a qualidade geral e o desempenho da tubagem da linha de travão.

Soluções

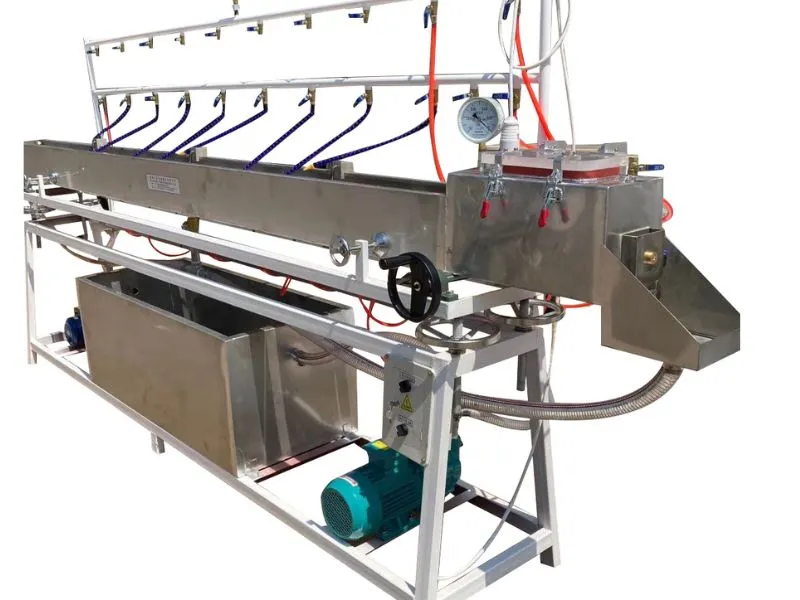

Implementar um controlo preciso da temperatura no tanque de arrefecimento. Utilizar um depósito de água de arrefecimento a vácuo para um arrefecimento uniforme e estabilidade dimensional. Monitorizar e ajustar regularmente o processo de arrefecimento para manter as dimensões consistentes da tubagem.