Línea de extrusión de manguera de ducha lisa multicolor

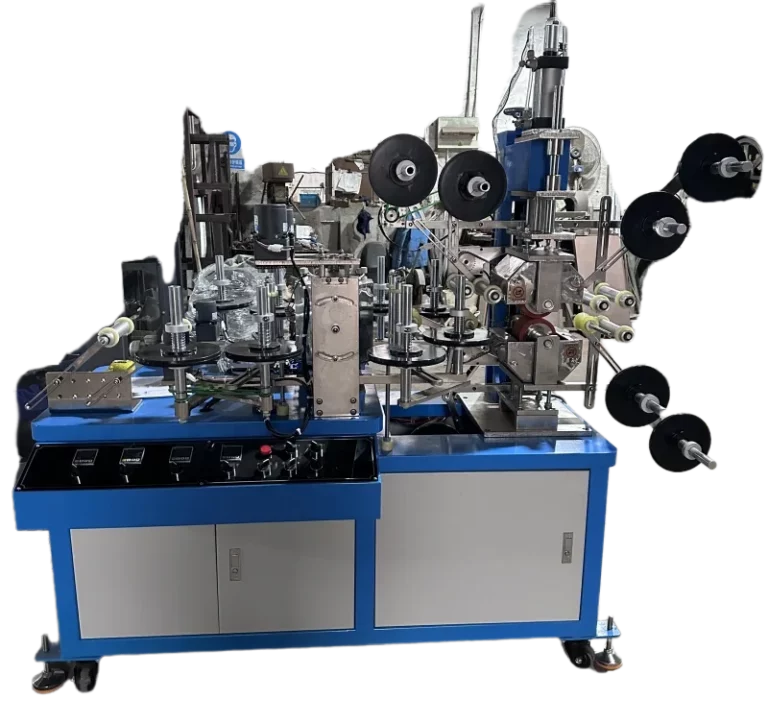

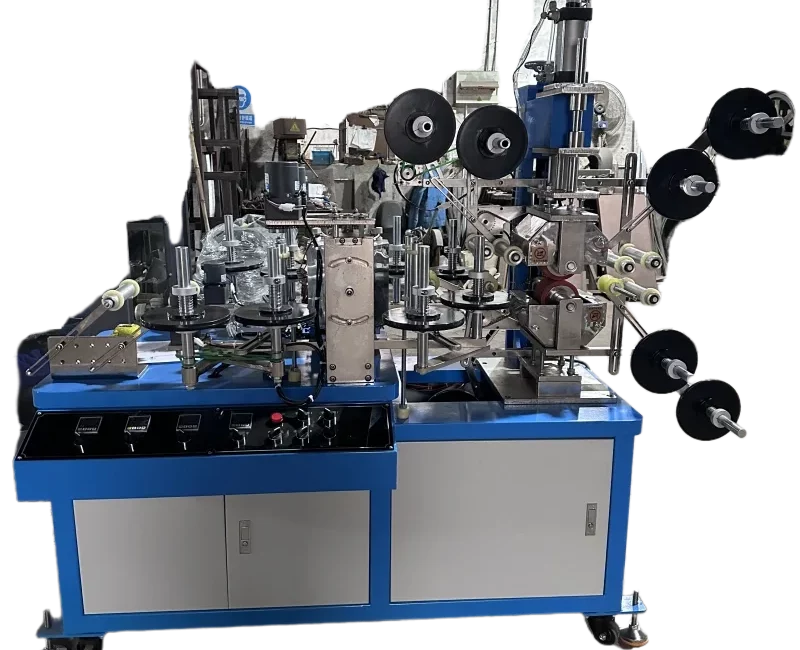

Máquina de recubrimiento con película: Recubrimiento de color de precisión para mangueras de ducha

Características principales:

- Revestimiento multidireccional: Aplica la película desde cuatro ángulos para un acabado impecable y sin costuras.

- Colores vivos y duraderos: La película de plata termofundida garantiza un brillo y una resistencia duraderos.

- Superficie lisa: Consigue un exterior plano y pulido que mejora tanto el aspecto como el tacto.

- Alta eficacia: La aplicación simultánea agiliza la producción manteniendo la calidad.

Con la máquina de revestimiento pelicular, puede producir mangueras de ducha que combinan una estética llamativa con un rendimiento fiable, lo que distingue a sus productos en un mercado competitivo.

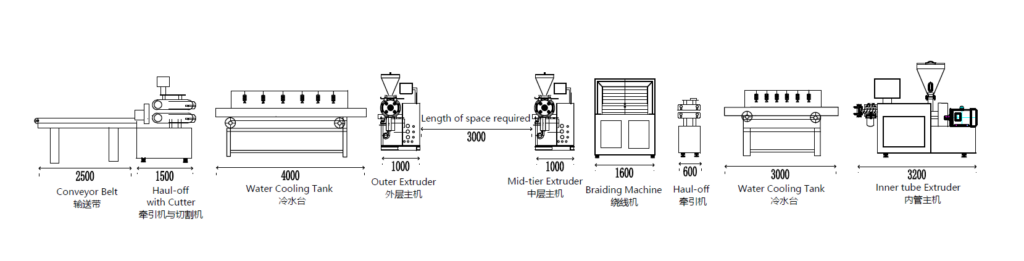

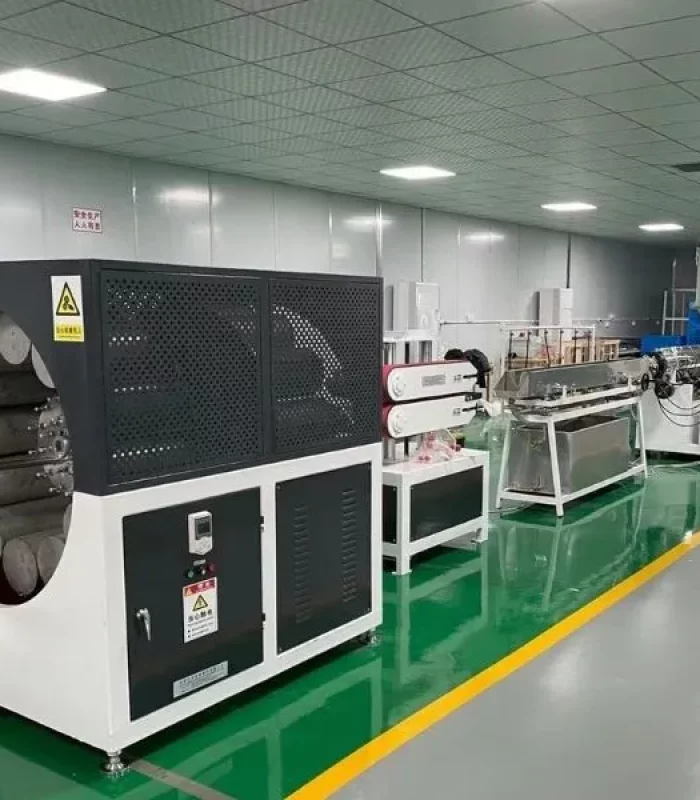

Disposición de la máquina de nuestra línea de extrusión de manguera de ducha lisa multicolor

Nuestra línea de extrusión de mangueras de ducha de PVC de color brillante está diseñada específicamente para crear mangueras de alta calidad y estéticamente atractivas con un exterior liso y coloreado.

La línea utiliza extrusoras principales dobles para la coextrusión, lo que permite la producción simultánea de las capas interior y exterior de la manguera. El depósito de refrigeración por agua garantiza que las mangueras mantengan su forma y estabilidad. El equipo de arrastre integrado y la servocortadora proporcionan un control preciso y cortes limpios.

Nuestro sistema exclusivo es el dispositivo de coloración de la capa exterior, que puede aplicar un acabado mate o brillante. El acabado brillante, sobre todo en plata brillante, es cada vez más popular, ya que ofrece un aspecto elegante y lujoso.

Y lo que es más importante, todas nuestras tintas colorantes han sido sometidas a pruebas de seguridad para el contacto humano y cumplen las estrictas normas de la UE.

Diferencia entre colores mates y brillantes

solicitar un presupuesto

¿Quiere saber más? Descubra nuestra línea de producción completa

Componentes clave de nuestra línea de extrusión de manguera de ducha lisa multicolor

Nuestra línea de extrusión de mangueras de ducha lisas se compone de varios componentes críticos que trabajan juntos para producir mangueras de ducha multicolores de alta calidad. Cada pieza está diseñada para ofrecer precisión y eficiencia.

Extrusora monohusillo de precisión

Garantiza un flujo de material constante para un grosor uniforme de la manguera.

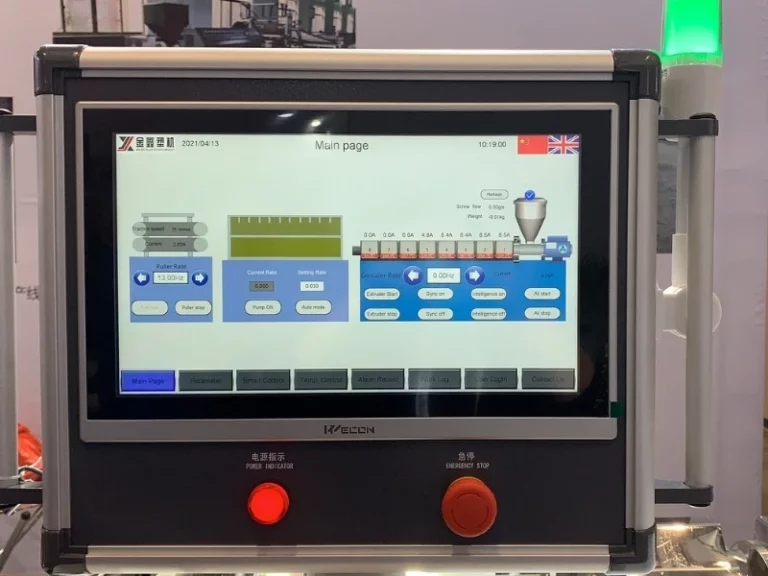

Control de la temperatura: Equipadas con sistemas de control PLC de última generación e interfaces de pantalla táctil, nuestras máquinas aseguran un control preciso del proceso de extrusión, garantizando una calidad superior en cada producción.

Sistema de refrigeración eficiente

Enfría rápidamente la manguera extruida para fijar su forma y calidad. Se pueden añadir depósitos de refrigeración adicionales si se necesitan varias extrusoras o un mayor rendimiento.

Ajusta rápidamente la forma de la manguera, manteniendo la calidad y acelerando la producción.

Unidad de recogida

Mecanismo de arrastre fiable: mantiene una tensión constante y unas dimensiones precisas durante la producción, garantizando que la manguera cumpla sus estándares de calidad.

Mantiene una tensión constante para dimensiones precisas.

Máquina trenzadora

Pieza clave de nuestra línea de extrusión de mangueras reforzadas con trenzado de PVC. Teje una capa de fibra o alambre metálico alrededor del tubo interior de PVC, mejorando en gran medida la fuerza, la resistencia a la presión y la durabilidad de la manguera.

Ofrece un funcionamiento a alta velocidad, ajustes personalizables y un control preciso para una calidad constante y una producción eficiente.

Máquina recubierta de película

La máquina Film-Coated recubre las mangueras de ducha con una capa de color duradera y sin costuras mediante película de plata y fusión por calor.

Crea un acabado liso y pulido que oculta la capa de refuerzo.

Esta tecnología garantiza un brillo duradero y resistencia al desgaste.

Opciones de acabado flexibles

La manguera acabada puede cortarse a longitudes personalizadas o enrollarse en rollos en función de sus requisitos de embalaje y entrega.

Línea de extrusión de manguera de ducha lisa multicolor Preguntas y respuestas

Puede ayudarle a saber más

¿Qué colores hay disponibles para las mangueras de ducha?

Nuestra línea de extrusión admite una amplia gama de colores, incluidos los acabados mate y brillante, para adaptarse a cualquier preferencia de diseño.

¿Afecta el revestimiento de color a la durabilidad de la manguera?

El revestimiento de color está diseñado para ser duradero y resistente al desgaste, lo que garantiza que la manguera mantenga su aspecto y funcionalidad con el paso del tiempo.

¿Pueden personalizarse las mangueras de ducha con motivos o características adicionales?

Sí, nuestra línea de extrusión de manguera de ducha lisa multicolor admite una amplia gama de estilos y diseños personalizados.

Podemos añadir motivos como logotipos o diseños exclusivos directamente en las mangueras. Además, ofrecemos características innovadoras, como películas que cambian de color en función de la temperatura del agua.

Todas estas opciones pueden personalizarse para adaptarse a sus necesidades específicas.

Acerca de JINXIN Plastic Machinery

Desde 2012

Somos honestos y fiables, y proporcionamos equipos rentables para su fábrica

Al elegir nuestros equipos, se está asociando con un proveedor dedicado a resolver sus puntos débiles con soluciones de alta calidad, rentables y elaboradas por expertos. Respaldamos la fiabilidad y el rendimiento de todos los productos que ofrecemos, garantizando que su inversión ofrezca los resultados que necesita para que su negocio prospere.

Calidad probada

Más de una década de experiencia y los comentarios de nuestros clientes garantizan que nuestras máquinas seleccionadas ofrezcan durabilidad a largo plazo y un rendimiento fiable.

Valor excepcional

Proporcionamos equipos de alta calidad a precios competitivos, maximizando su inversión con un rendimiento de primer nivel.

Asistencia fiable

La asistencia y el servicio integrales garantizan un funcionamiento sin problemas y un tiempo de inactividad mínimo, manteniendo una productividad óptima.

Nuestros clientes opinan

Nuestros increíbles proveedores

SOLUCIONES DE EXTRUSIÓN

Dirección de correo electrónico

sales@jfextruder.com

Dirección de la fábrica

No. 31 Yuci Rd., Yuyao, Ciudad de Ningbo, Provincia de Zhejiang, China