Moisture Absorption

PA12 is known for its low moisture absorption, but any moisture present in the raw material can lead to issues such as bubbles and surface defects in the extruded tubing.

Solutions

Pre-dry the PA12 pellets thoroughly before extrusion. Utilize a dehumidifying dryer to ensure the material is moisture-free, preventing defects caused by moisture absorption.

Surface Defects (Sharkskin, Melt Fracture)

Surface defects like sharkskin and melt fracture can occur due to high shear rates during extrusion, resulting in rough or irregular tubing surfaces.

Solutions

Adjust the extrusion parameters by lowering the shear rate and extruder speed. Ensure proper temperature settings to reduce melt viscosity and improve surface finish.

Dimensional Stability

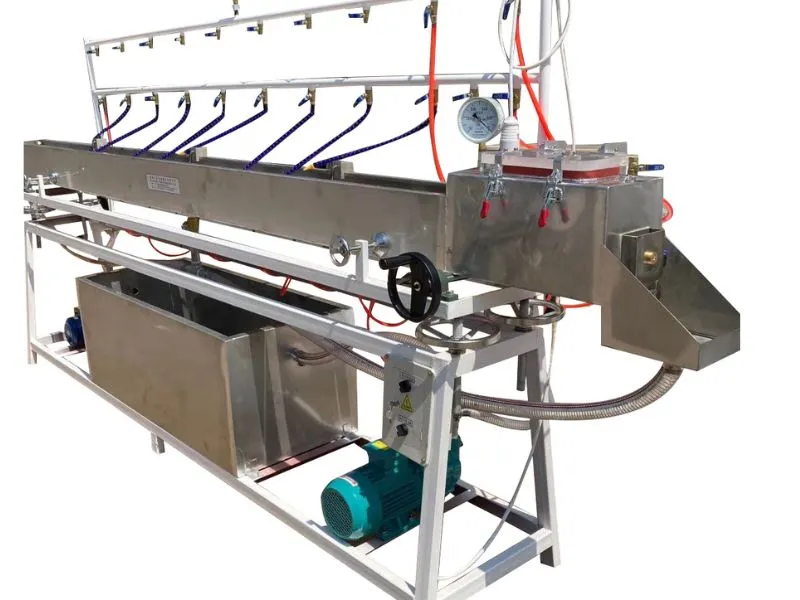

Inconsistent cooling can lead to variations in tubing dimensions, affecting the overall quality and performance of the brake line tubing.

Solutions

Implement precise temperature control in the cooling tank. Use a vacuum cooling water tank for uniform cooling and dimensional stability. Regularly monitor and adjust the cooling process to maintain consistent tubing dimensions.