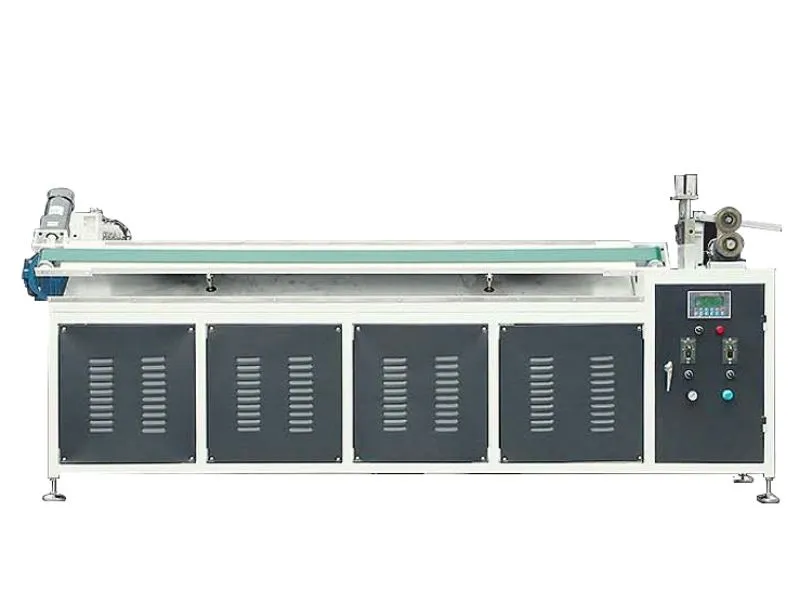

PVC Braided Reinforced Hose Extrusion Line

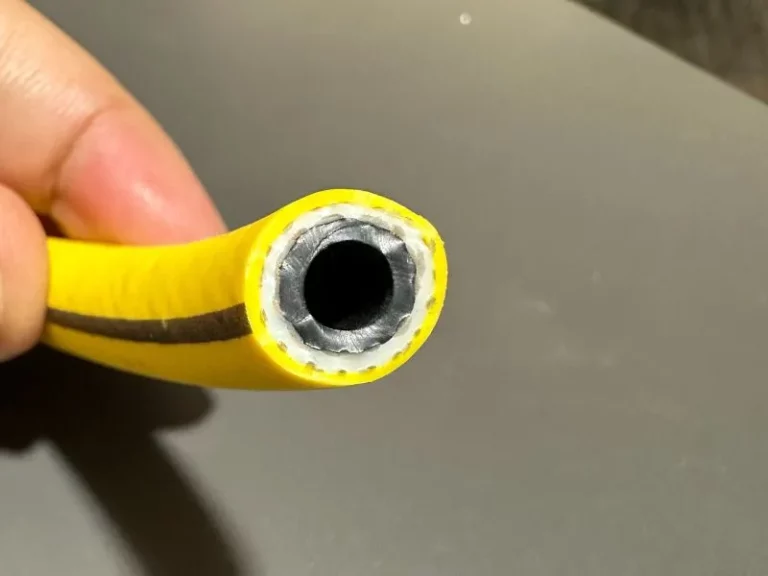

Produce high-quality, durable PVC braided reinforced hoses for a multitude of applications, from robust garden hoses to reliable washing machine inlet pipes.

Our extrusion lines are engineered for precision, efficiency, and consistent output.

Key Features & Advantages of Our Reinforced Hose Machine

High Strength Output

Produces hoses with excellent pressure resistance for demanding applications.

Versatile Production

Manufacturing garden hoses, washing machine inlet pipes, air pressure hoses, agricultural water hoses, etc.

Durable Construction

Built with high-quality components for long service life and stable operation.

Durable Construction

Built with high-quality components for long service life and stable operation.

Durable Construction

Built with high-quality components for long service life and stable operation.

Customizable Configurations

Options available for different hose diameters, layers (e.g., 2-layer, 3-layer), and output capacities.

REQUEST A quote

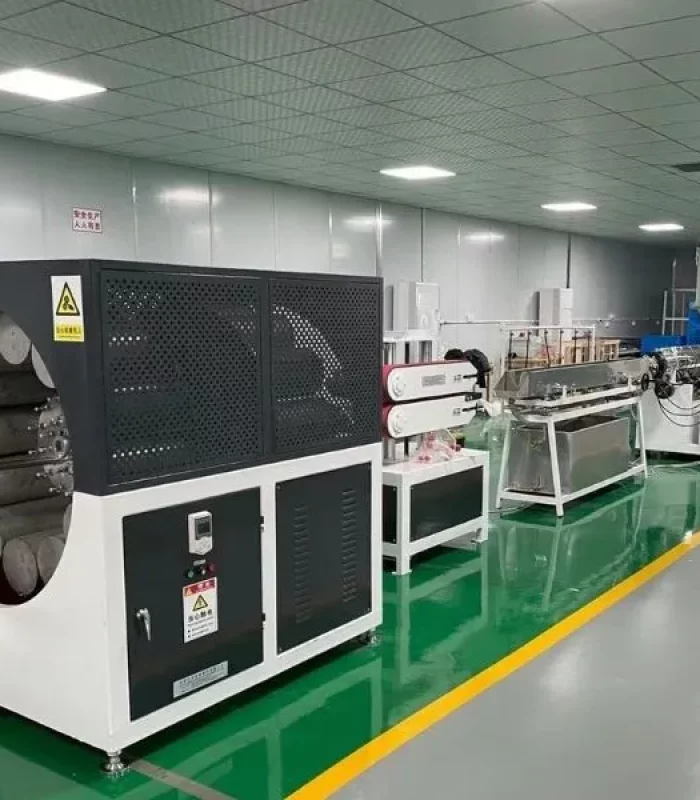

Want to Know More? Discover Our Full Production Line Below

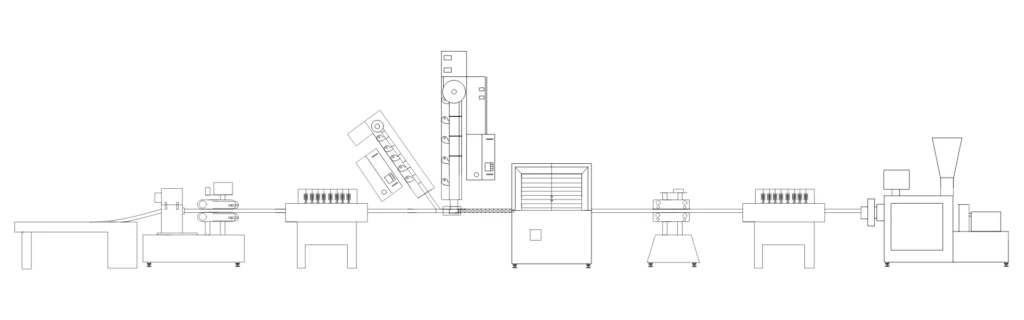

PVC Braided Hose Line Composition & Technical Specifications

Our extrusion line is built for versatility and efficiency. The components listed below reflect the standard configuration for producing high-quality PVC braided reinforced hoses. For specialized needs—such as three-layer hoses requiring additional extruders, color marking lines needing extra marking units, or increased cooling capacity with more tanks—custom configurations are available. Each setup is tailored to your specific production demands.

Precision Single-Screw Extruder

The core of the extrusion line, this extruder ensures a steady PVC flow for uniform hose thickness.

For three-layer hoses, additional extruders can be integrated based on your needs.

Efficient Cooling System

Cools the extruded hose rapidly to lock in shape and quality. Additional cooling tanks can be added if multiple extruders or higher output is required.

Haul-Off Unit

Reliable Haul-Off Mechanism-Maintains consistent tension and precise dimensions during production, ensuring the hose meets your quality standards.

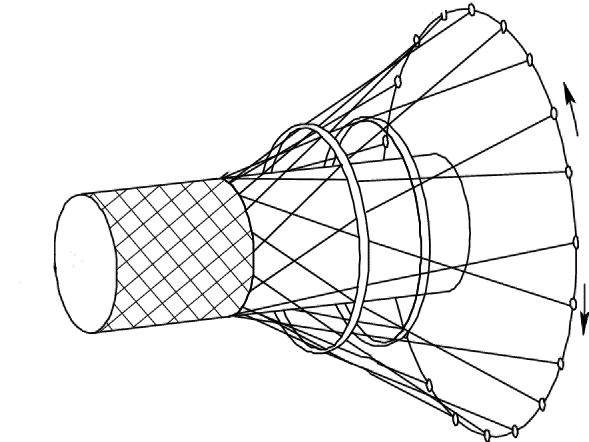

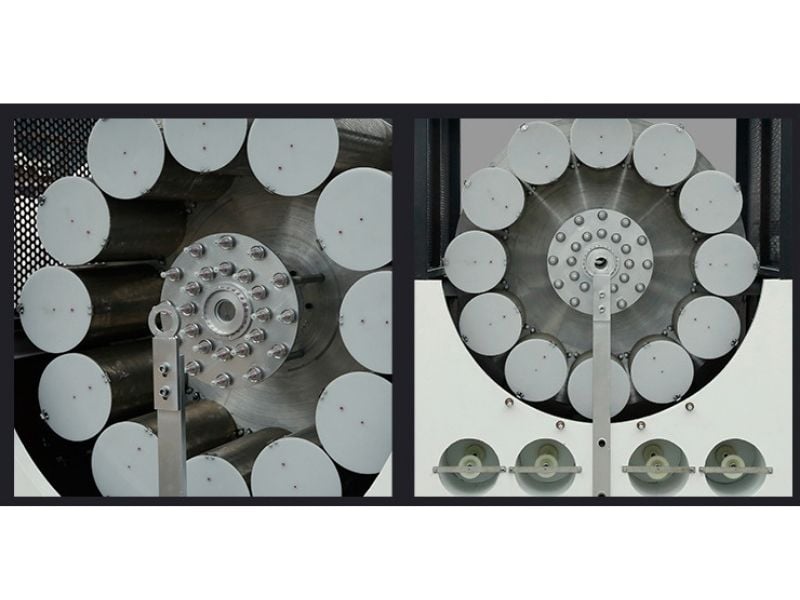

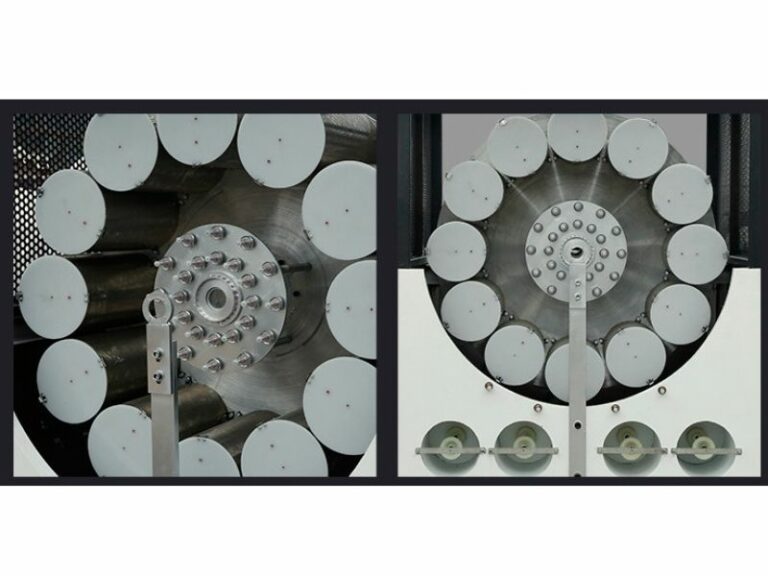

Braiding Machine

Key part of our PVC Braided Reinforced Hose Extrusion Line. It weaves a layer of fiber or metal wire around the inner PVC tube, greatly improving the hose’s strength, pressure resistance, and durability.

It offers high-speed operation, customizable settings, and precise control for consistent quality and efficient production.

Winer

Flexible Finishing Options

The finished hose can be wound into rolls, depending on your packaging and delivery requirements

Cutter

Flexible Finishing Options

The finished hose can be cut to custom lengths depending on your packaging and delivery requirements.

The Role of Braiding Machines in Manufacturing PVC Braided Reinforced Tubing

Precision Control

Modern braiding machines are equipped with advanced control systems. These systems allow for precise adjustments in the braiding pattern, tension, and speed, ensuring uniformity and consistency in the finished product.

High-Speed Operation

To meet industrial demands, these machines operate at high speeds, significantly reducing production time while maintaining quality.

Automated Functionality

Automation in winding machines minimizes human error and increases efficiency. Automated loading and unloading of the tubes, as well as automated adjustments during the winding process

Reinforced PVC Hose Extrusion Line Related Q&A

May help you know more

What types of hoses can be produced with this extrusion line?

Our PVC Braided Reinforced Hose Extrusion Line is versatile, capable of producing a wide range of hoses including garden hoses, industrial hoses, and high-pressure reinforced hoses. It accommodates various diameters and lengths to meet your specific needs.

Is specialized training required to operate this equipment?

While our equipment is advanced, it’s designed for user-friendly operation. We provide comprehensive training with every purchase, and our dedicated support team is always available to assist, ensuring you can operate the line confidently and effectively.

How do I determine if this extrusion equipment is suitable for my production needs?

When inquiring about equipment, provide detailed images and specifications of the hoses you intend to produce. This helps ensure the equipment is customized to meet your specific requirements, particularly regarding the braiding machine and the type of braiding yarn used.

Why Choose JINXIN's PVC Yarn Reinforced Hose Machine?

Since 2012

We are honest and reliable, providing cost-effective equipment for your factory

By choosing our equipment, you are partnering with a supplier dedicated to resolving your pain points with expertly curated, high-quality, and cost-effective solutions.

We stand by the reliability and performance of every product we offer, ensuring that your investment delivers the results you need for your business to thrive.

Proven Quality

Over a decade of experience and customer feedback ensures our selected machines offer long-term durability and reliable performance.

Exceptional Value

We provide high-quality equipment at competitive prices, maximizing your investment with top-tier performance.

Reliable Support

Comprehensive support and service ensure smooth operation and minimal downtime, maintaining optimal productivity.

Our Customers Say

Our amazing Suppliers

EXTRUSION SOLUTIONS

Email Address

sales@jfextruder.com

Factory Address

No. 31 Yuci Rd., Yuyao, Ningbo City, Zhejiang Province, China