Linha avançada de co-extrusão de perfis de PVC: O seu especialista em máquinas de perfis de PVC rígido-flexível

pedir um orçamento

Quer saber mais? Descubra a nossa linha de produção completa abaixo

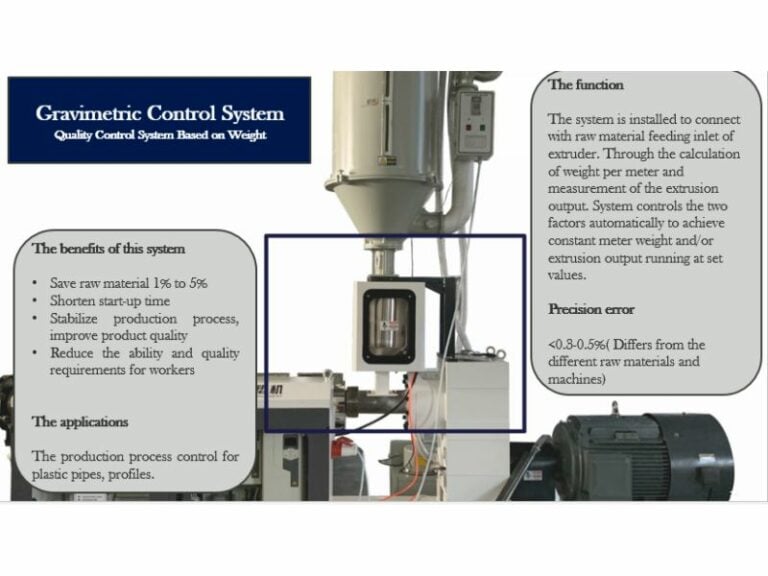

Extrusoras eficientes para a sua máquina de perfis de PVC rígido-flexível

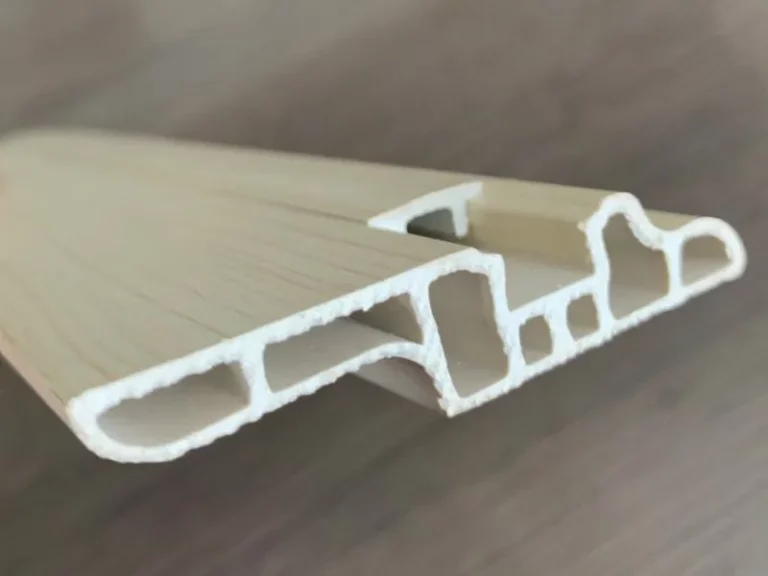

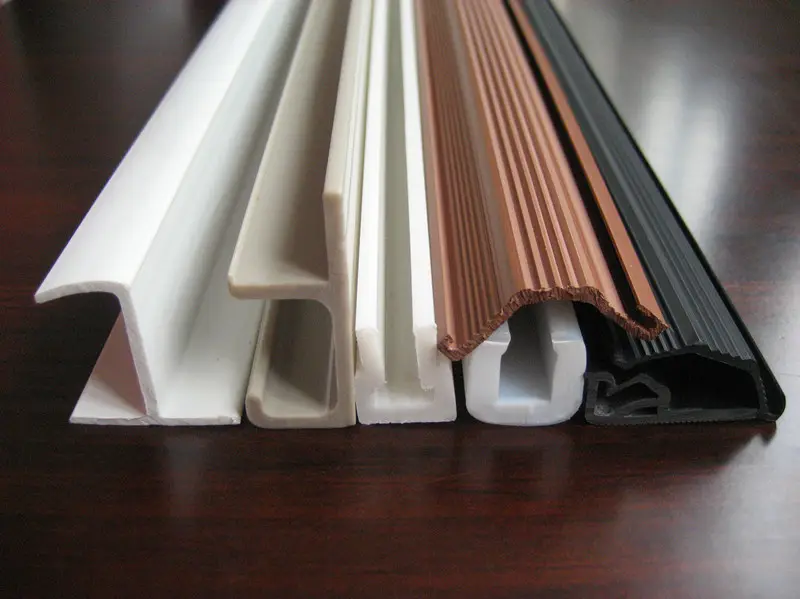

Investir num Linha de co-extrusão de perfis de PVC, em particular um que se destaca como Máquina de perfis de PVC rígido-flexívelabre um mundo de possibilidades. Quer se trate de vedantes de janelas, juntas industriais ou guarnições decorativas multicomponentes, os nossos Linha de co-extrusão de perfis de PVC foi concebida para esta versatilidade.

Esta secção descreve em pormenor a forma como a nossa Linha de co-extrusão de perfis de PVC (ideal para grânulos de PVC) permite-lhe obter designs rígidos-flexíveis complexos e acabamentos de superfície superiores, o que a torna uma das principais Máquina de perfis de PVC rígido-flexível solução.

Extrusoras eficientes para a sua máquina de perfis de PVC rígido-flexível

Extrusoras de parafuso simples eficientes para a sua máquina de perfis de PVC rígido-flexível

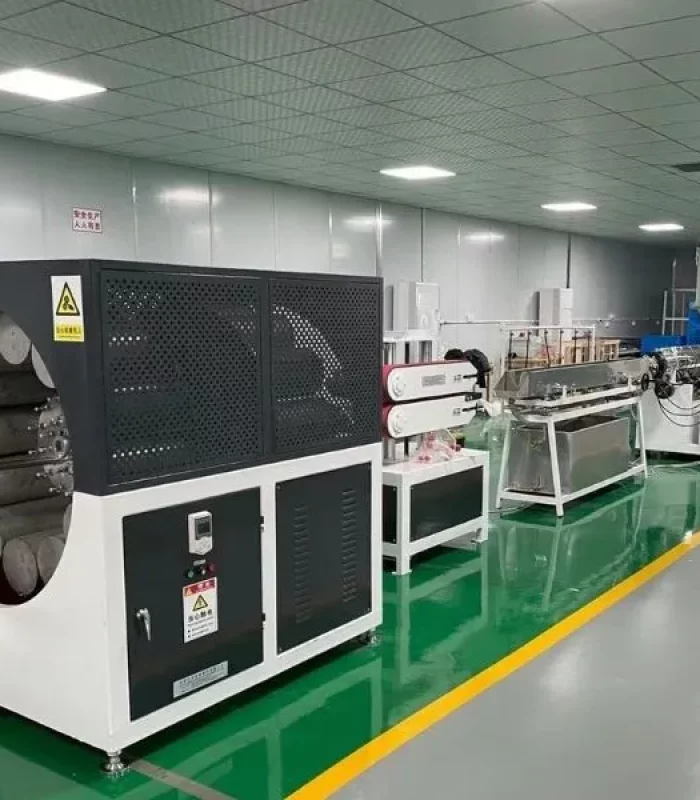

A nossa linha de co-extrusão de perfis de PVC utiliza normalmente extrusoras de parafuso único robustas, o que a torna uma máquina de perfis de PVC rígido-flexível eficaz.

Estas são optimizadas para grânulos de PVC, formando o perfil rígido primário, enquanto uma extrusora auxiliar mais pequena na sua linha de co-extrusão de perfis de PVC adiciona perfeitamente a camada flexível co-extrudida.

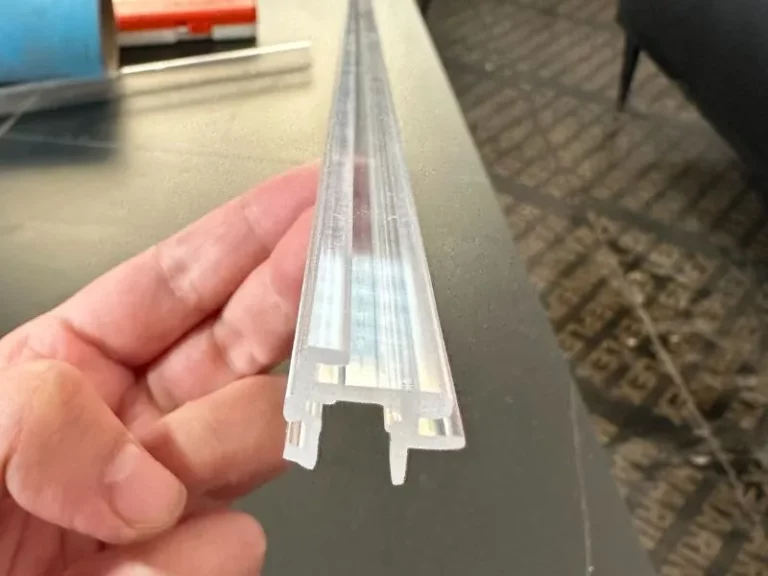

Matrizes de coextrusão de precisão e calibração avançada para um acabamento superior

A cabeça da matriz de co-extrusão e a calibração subsequente são fundamentais para uma linha de co-extrusão de perfis de PVC bem sucedida, especialmente quando funciona como uma máquina de perfis de PVC rígido-flexível ou quando se pretende obter superfícies espelhadas e de alto brilho.

As nossas concepções avançadas de matrizes e os calibradores de precisão com controlo de temperatura garantem um fluxo de material ótimo, uma estratificação precisa dos materiais de PVC e uma qualidade de superfície excecional.

Esta tecnologia também permite o processamento eficaz de compostos de PVC com maior teor de carga, mantendo uma excelente integridade e acabamento do perfil na sua linha de co-extrusão de perfis de PVC.

Refrigeração fiável a jusante e especializada para perfis de PVC de alta precisão

Uma linha completa de co-extrusão de perfis de PVC, concebida como uma máquina de perfis de PVC rígido-flexível abrangente, inclui equipamento a jusante de alta qualidade.

As nossas mesas de calibração a vácuo possuem sistemas de arrefecimento optimizados e zonas de controlo de temperatura precisas** para garantir um dimensionamento preciso e alcançar uma precisão dimensional ultra-alta para aplicações exigentes.

Este cuidadoso processo de arrefecimento é fundamental para produzir perfis de PVC rígido com uma estabilidade excecional e um acabamento impecável a partir da sua linha de co-extrusão de perfis.

Linha de Coextrusão de Perfil em PVC Perguntas e Respostas Relacionadas

Pode ajudá-lo a saber mais

Como é que se garante uma ligação adequada entre as camadas de PVC macio e duro na co-extrusão?

Seleccionamos materiais de PVC com propriedades de fusão correspondentes para uma colagem perfeita. O nosso equipamento mantém uma temperatura e pressão precisas para evitar a delaminação. Além disso, os nossos moldes de precisão asseguram um alinhamento consistente das camadas para um acabamento perfeito.

Precisamos de produzir perfis de PVC com uma superfície de alto brilho, quase espelhada. A vossa linha de co-extrusão de perfis de PVC consegue atingir este objetivo?

Sim, conseguir um acabamento de alto brilho ou mesmo espelhado nos perfis de PVC é uma capacidade que podemos integrar na sua linha de extrusão de perfis de PVC.

Isto envolve uma combinação de conceção especializada de matrizes, superfícies de calibração maquinadas com precisão e um controlo meticuloso da temperatura ao longo das fases de calibração a vácuo e de arrefecimento.

Podemos discutir os seus requisitos específicos de acabamento de superfície.

Que apoio oferecem para o desenvolvimento de um novo perfil nesta máquina de perfis de PVC rígido-flexível?

Oferecemos um apoio abrangente para os seus projectos de **linha de co-extrusão de perfis de PVC**, especialmente quando se pretende obter resultados complexos como os de uma máquina de perfis de PVC rígido-flexível.

Isto inclui a consulta, a colaboração na conceção de matrizes e a entrada em funcionamento total da linha de extrusão de perfis de PVC.

Sobre a JINXIN Plastic Machinery

Desde 2012

Somos honestos e fiáveis, fornecendo equipamento rentável para a sua fábrica

Ao escolher o nosso equipamento, está a estabelecer uma parceria com um fornecedor dedicado a resolver os seus problemas com soluções especializadas, de alta qualidade e económicas. Garantimos a fiabilidade e o desempenho de todos os produtos que oferecemos, assegurando que o seu investimento proporciona os resultados de que necessita para o seu negócio prosperar.

Qualidade comprovada

Mais de uma década de experiência e feedback dos clientes garantem que as nossas máquinas seleccionadas oferecem uma durabilidade a longo prazo e um desempenho fiável.

Valor excecional

Fornecemos equipamento de alta qualidade a preços competitivos, maximizando o seu investimento com um desempenho de topo.

Apoio fiável

A assistência e o serviço abrangentes garantem um funcionamento sem problemas e um tempo de inatividade mínimo, mantendo uma produtividade óptima.

O que dizem os nossos clientes

Os nossos fantásticos fornecedores

SOLUÇÕES DE EXTRUSÃO

Endereço de correio eletrónico

sales@jfextruder.com

Endereço da fábrica

No. 31 Yuci Rd., Yuyao, cidade de Ningbo, província de Zhejiang, China