About JINXIN Plastic Machinery

Since 2012

We are honest and reliable, providing cost-effective equipment for your factory

By choosing our equipment, you are partnering with a supplier dedicated to resolving your pain points with expertly curated, high-quality, and cost-effective solutions. We stand by the reliability and performance of every product we offer, ensuring that your investment delivers the results you need for your business to thrive.

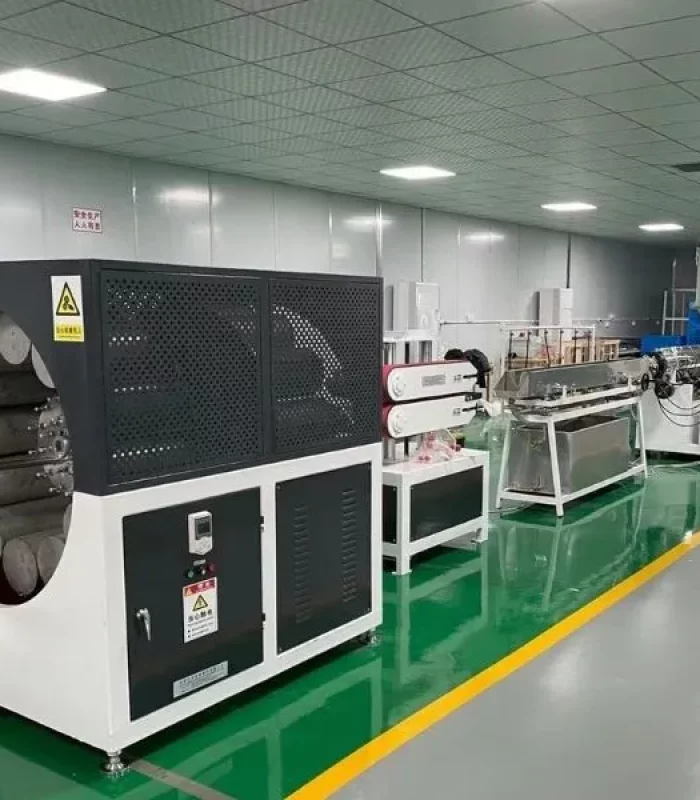

Extruders Warehouse

Reliable electronic components are utilized

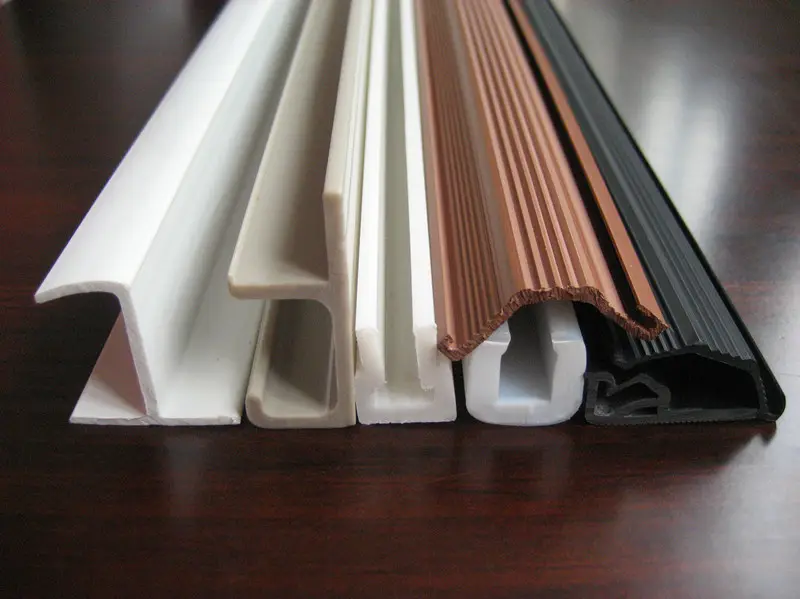

Extrusion Precision

Meets Most Factory Standards

Long-standing Good Reputation

Delivering Value to Customers

Machine Packaging