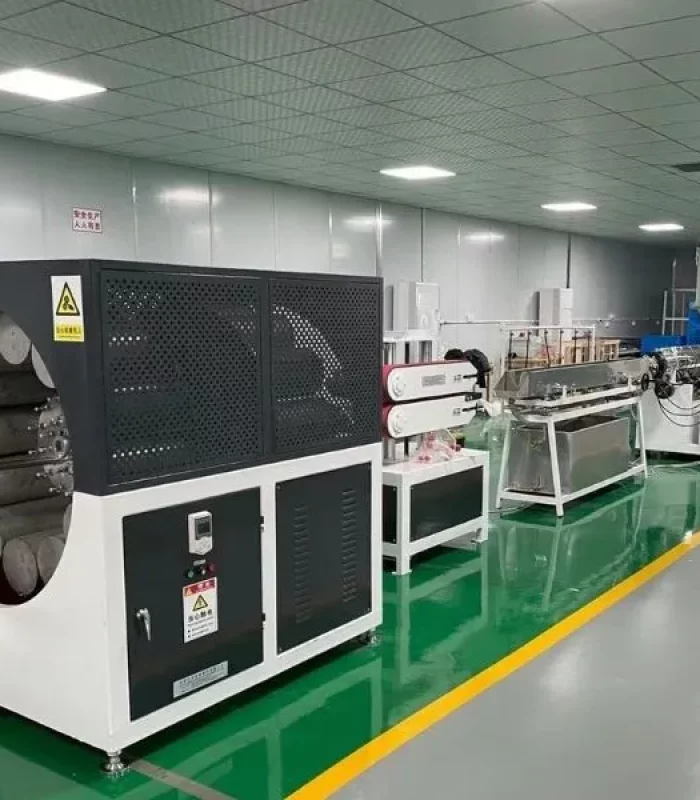

Advanced PC/PMMA LED Profile Extrusion Machines

Mastering Production with Your PC PMMA LED Profile Extrusion Machine

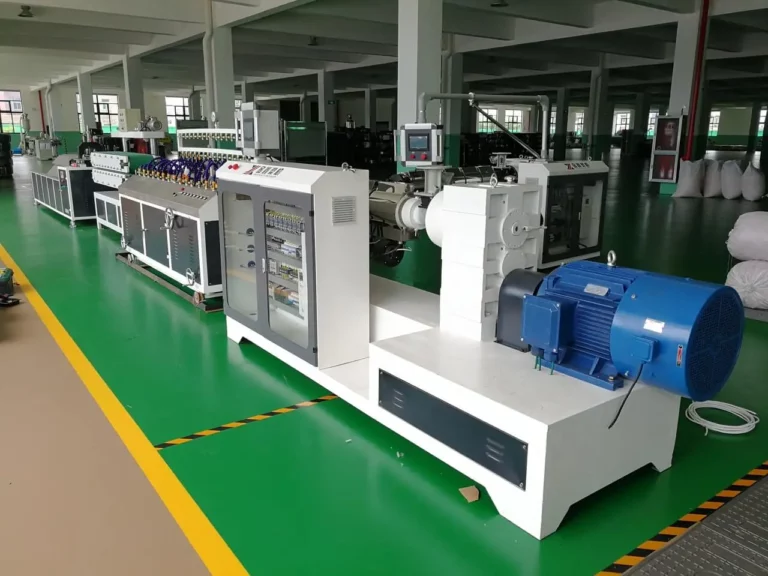

Manufacturing high-quality LED lighting profiles with a PC PMMA LED Profile Extrusion Machine requires more than standard equipment; it demands deep material understanding and precision engineering.

This section explores how our specialized PC PMMA LED Profile Extrusion Machine and expertise help you overcome challenges in producing complex optical profiles from Polycarbonate (PC) and PMMA (Acrylic).

We ensure your PC PMMA LED Profile Extrusion Machine delivers end products meeting the highest standards. We are your technical partner for innovative solutions powered by our advanced PC PMMA LED Profile Extrusion Machine technology.

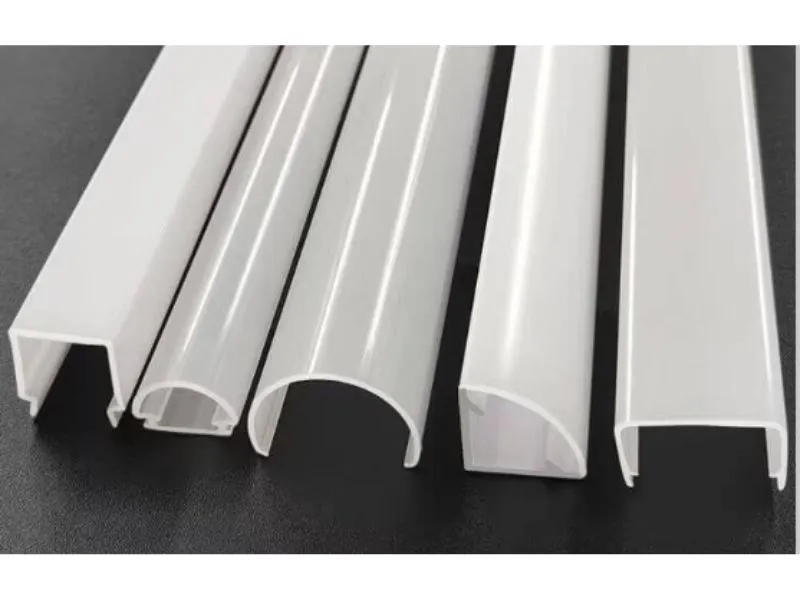

High-Precision Die & Calibration Technology: The Key to Perfection

We understand that the die is the heart of profile extrusion. Our expertise lies in designing and collaborating on high-precision dies and calibrators for complex LED shapes. This ensures accurate dimensions, sharp details, and smooth surfaces, even for intricate multi-cavity or co-extruded designs.

Downstream Equipment for Delicate Profiles: Careful Handling

Our downstream equipment, including vacuum calibration tables, haul-off units, and cutters, is designed for the careful handling of optical profiles to prevent scratches, deformation, and stress. Options for protective film lamination are available to preserve surface quality.

Material Drying & Pre-treatment: Ensuring Optimal Processing

PC and PMMA are hygroscopic and require thorough drying before extrusion to prevent defects like bubbles or silver streaks. Our solutions integrate efficient drying systems to prepare materials optimally for flawless profile production.

Advanced Control System with Process Monitoring

An intelligent PLC control system provides precise control over all parameters, from temperature to speed. Real-time monitoring helps maintain process stability, crucial for achieving consistent quality in long production runs of optical profiles.

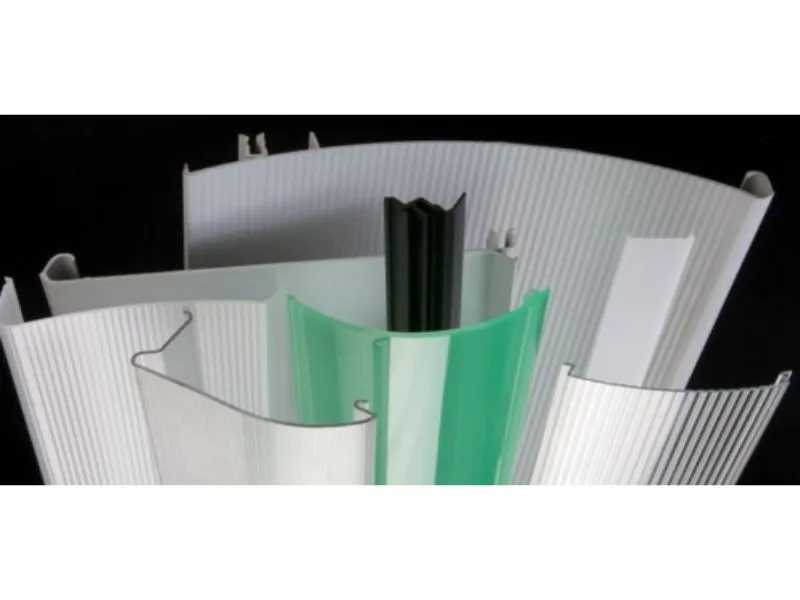

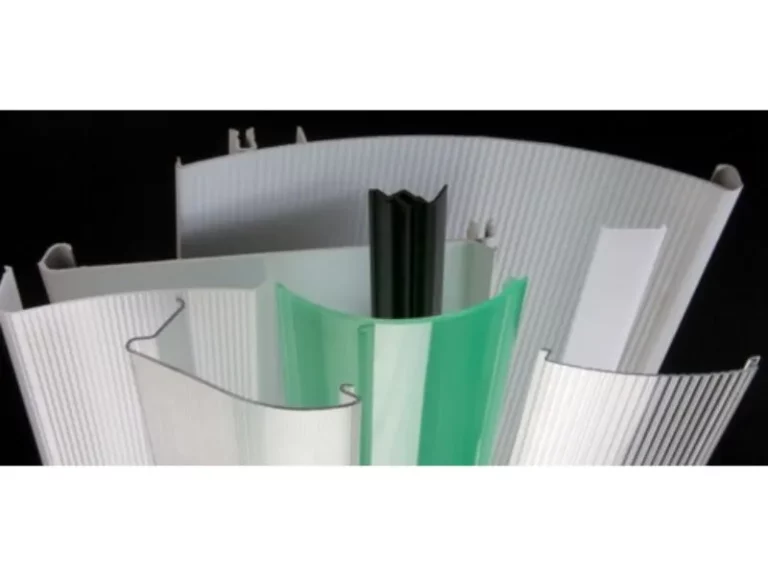

Co-extrusion Capabilities for Enhanced Functionality

Explore multi-layer or multi-color LED profiles with our co-extrusion technology. Combine materials to achieve specific optical effects, enhance durability, or integrate different functionalities within a single profile.

Discuss Your Project

Want to Know More? Discover Our PC PMMA LED Profile Extrusion Machine Below

Your PC PMMA LED Profile Extrusion Machine: Key Questions Answered

May help you know more

We have a unique LED profile design. How can your PC PMMA LED Profile Extrusion Machine solution help us?

This is precisely where we excel. We partner with clients who have innovative designs. You provide the profile concept/drawings, and our team, along with experienced die makers, will work closely with you to develop the optimal die design and a complete extrusion process.

We guide you through material selection and process parameters to turn your vision into a high-quality physical product. Our goal is a collaborative success.

What are the common challenges in extruding PC and PMMA for optical applications, and how does your equipment address them?

Key challenges include material degradation (yellowing, black specks), achieving high clarity/transparency, and maintaining tight dimensional tolerances.

Our machines address these with:

1) Specialized screw geometry and temperature control to minimize shear and prevent overheating.

2) High-precision dies and careful calibration for accurate profiles.

3) Robust pre-drying systems to eliminate moisture-related defects. This ensures you produce optically clear and dimensionally stable LED profiles.

How do you protect our proprietary designs when discussing a PC PMMA LED Profile Extrusion Machine project?

We fully respect design confidentiality for any PC PMMA LED Profile Extrusion Machine project. We readily sign NDAs before detailed technical discussions about your **PC PMMA LED Profile Extrusion Machine** or die designs. Trust is paramount.

About JINXIN Plastic Machinery

Since 2012

We are honest and reliable, providing cost-effective equipment for your factory

By choosing our equipment, you are partnering with a supplier dedicated to resolving your pain points with expertly curated, high-quality, and cost-effective solutions. We stand by the reliability and performance of every product we offer, ensuring that your investment delivers the results you need for your business to thrive.

Proven Quality

Over a decade of experience and customer feedback ensures our selected machines offer long-term durability and reliable performance.

Exceptional Value

We provide high-quality equipment at competitive prices, maximizing your investment with top-tier performance.

Reliable Support

Comprehensive support and service ensure smooth operation and minimal downtime, maintaining optimal productivity.

Our Customers Say

Our amazing Suppliers

EXTRUSION SOLUTIONS

Email Address

sales@jfextruder.com

Factory Address

No. 31 Yuci Rd., Yuyao, Ningbo City, Zhejiang Province, China