Inconsistent Pipe Wall Thickness:

Variations in pipe wall thickness lead to weak points, causing leaks or failures.

Solutions

Our machine's advanced die and cooling systems ensure uniform wall thickness by maintaining precise temperature and alignment control.

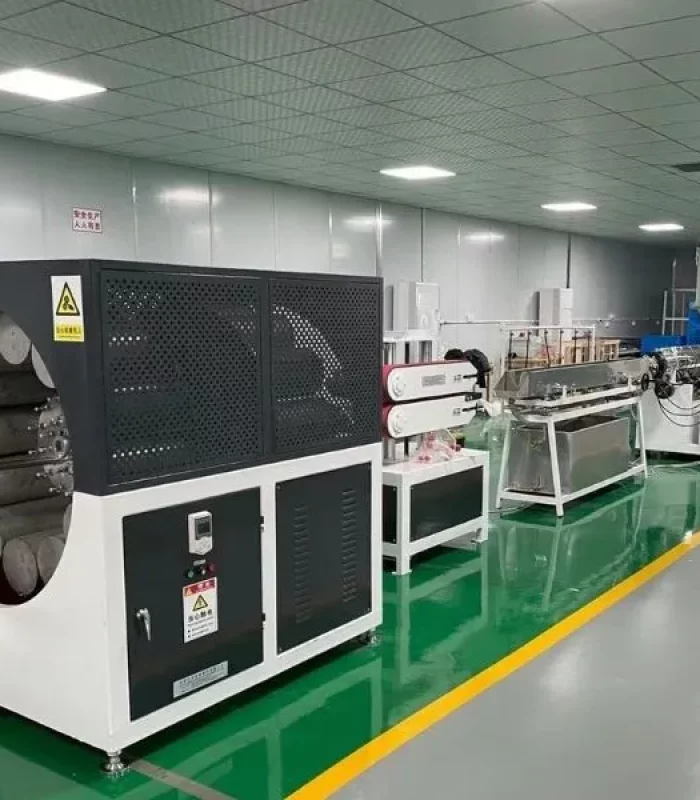

High Operational Costs

High energy consumption and frequent maintenance increase operational costs.

Solutions

The energy-efficient design of our extruder reduces power consumption and robust construction minimizes maintenance needs, lowering overall costs

Poor Product Quality

Inconsistent product quality leads to customer dissatisfaction and increased returns.

Solutions

Precise control systems ensure consistent extrusion parameters, and effective cooling and calibration result in high-quality finished products