HDPE Pipe Extrusion Machine for Small Diameter PP/PE/PPR Pipes

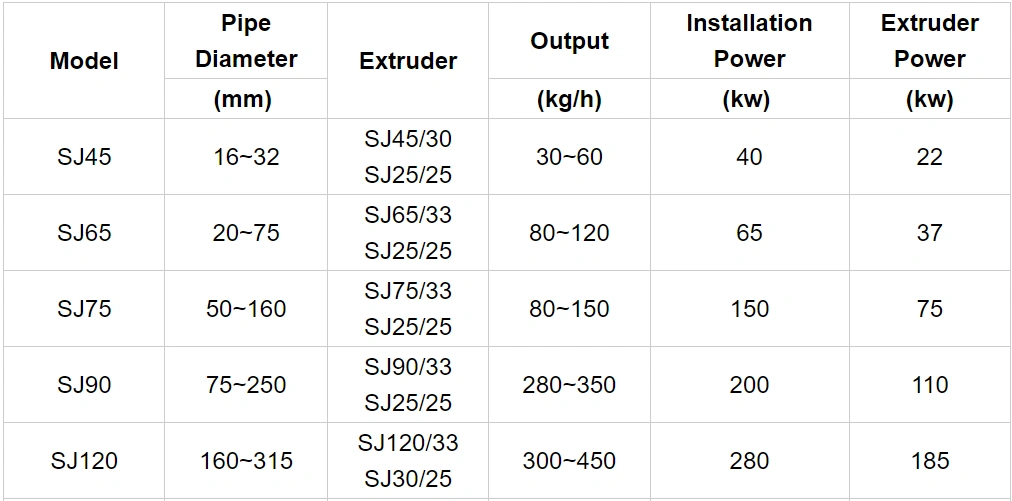

Detailed Parameters of PE/PP/PPR Pipe Extrusion Machine Line

The item “Extruder” in the figure below contains an auxiliary extruder for extruding the marking lines.

REQUEST A quote

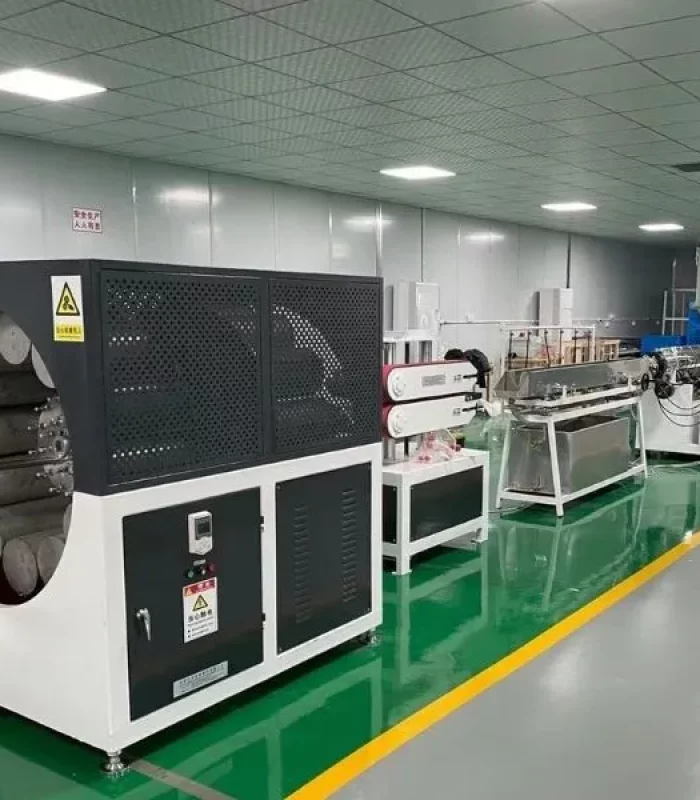

Want to Know More? Discover Our Full Production Line Below

Compatibility with PP, PE and PP-R Materials

PE PP Pipe Production Line Parts

Main Extruder

The main HDPE extruder machine is the core component where PE/PP/PP-R pellets are melted and homogenized. It consists of a barrel, screw, and heaters. The rotating screw, driven by a powerful motor, pushes the pellets through the barrel, where they are gradually melted by the heat.

Temperature Control: Equipped with state-of-the-art PLC control systems and touch screen interfaces, our machines ensure precise control over the extrusion process, guaranteeing superior quality in every production run.

Vacuum Sizing Tank

The vacuum sizing tank stabilizes the shape of the molten PE/PP/PPR pipe by using a vacuum to pull it against the sizing sleeve. This process ensures that the pipe retains its correct dimensions as it cools and solidifies.

Details:

- Cooling System: Equipped with an efficient cooling system to rapidly solidify the pipe.

- Adjustable Spray Angle: Allows for precise control of the cooling process, enhancing dimensional stability

Cooling Tank

The cooling tank further cools the pipe to ensure its structural integrity and dimensional accuracy. It usually follows the vacuum sizing tank in the production line.

Details:

- Length: Typically designed in segments to provide adequate cooling.

- Cooling Method: Uses water sprays or baths to evenly cool the pipe, preventing warping and ensuring uniform thickness

Haul-Off Unit

The haul-off unit pulls the pipe through the extrusion line at a consistent speed, which is crucial for maintaining uniform diameter and wall thickness.

Details:

- Caterpillar Tracks: Multiple tracks driven by independent motors ensure smooth and even pulling.

- Speed Control: Precisely adjustable to match the extrusion speed and ensure product consistency

Cutter

The cutter precisely cuts the extruded pipes to the required lengths. This unit is designed to make clean, accurate cuts without damaging the pipes.

Details:

- Type: Non-dust or planetary cutters are commonly used for their precision and efficiency.

- Operation: Often equipped with servo motors for enhanced control and adaptability to different pipe sizes

HDPE PIPE EXTRUSION MACHINE LINE Q&A

May help you know more

How does the cooling and calibration system ensure roundness and dimensional accuracy?

What automation features reduce manual intervention and enhance production stability?

How hard is it to maintain my PE/PP/PPR pipe extrusion machine?

Maintaining a PE/PP/PPR pipe extrusion machine involves moderate effort, but with a structured plan, it becomes manageable and ensures long-term reliability. Below is a breakdown of the maintenance tasks by difficulty:

- Daily Maintenance

- Cleaning: After each use, remove debris and plastic residue. This is simple but requires consistency.

- Lubrication: Apply lubricant to moving parts like bearings to reduce wear. This is an easy yet essential task.

- Parameter Monitoring: Check pressure, temperature, and speed. Modern machines often include automated systems, making this straightforward.

- Periodic Maintenance

- Heating Element Care: Clean and inspect heating elements to ensure consistent melt quality. This requires some technical know-how.

- Screw and Barrel Inspection: Annually check for wear. This is more involved and may require professional help.

- Calibration: Periodically calibrate instruments like pressure gauges. This typically needs a technician’s expertise.

- Advanced Maintenance

- Gearbox Care: Replace lubricant every 3,000 hours and inspect annually. This is complex and often requires an expert.

- Electrical System: Regularly check wiring and insulation. This demands electrical knowledge and can be challenging.

- Vacuum Calibration Tank: Clean filters and the pump system routinely. This is critical for quality but can be intricate.

About JINXIN Plastic Machinery

Since 2012

We are honest and reliable, providing cost-effective equipment for your factory

By choosing our equipment, you are partnering with a supplier dedicated to resolving your pain points with expertly curated, high-quality, and cost-effective solutions. We stand by the reliability and performance of every product we offer, ensuring that your investment delivers the results you need for your business to thrive.

Proven Quality

Over a decade of experience and customer feedback ensures our selected machines offer long-term durability and reliable performance.

Exceptional Value

We provide high-quality equipment at competitive prices, maximizing your investment with top-tier performance.

Reliable Support

Comprehensive support and service ensure smooth operation and minimal downtime, maintaining optimal productivity.

Our Customers Say

Our amazing Suppliers

EXTRUSION SOLUTIONS

Email Address

sales@jfextruder.com

Factory Address

No. 31 Yuci Rd., Yuyao, Ningbo City, Zhejiang Province, China