Machines avancées d'extrusion de profilés LED en PC/PMMA

Maîtriser la production avec votre machine d'extrusion de profilés LED en PC PMMA

Fabrication de profilés d'éclairage LED de haute qualité avec un Machine d'extrusion de profilés LED en PC PMMA nécessite plus qu'un équipement standard ; elle exige une connaissance approfondie des matériaux et une ingénierie de précision.

Cette section étudie la manière dont nos Machine d'extrusion de profilés LED en PC PMMA et son expertise vous aident à relever les défis liés à la production de profils optiques complexes en polycarbonate (PC) et en PMMA (acrylique).

Nous veillons à ce que votre machine d'extrusion de profilés LED en PC PMMA produise des produits finis répondant aux normes les plus strictes. Nous sommes votre partenaire technique pour des solutions innovantes basées sur notre technologie avancée de machine d'extrusion de profilés LED en PC PMMA.

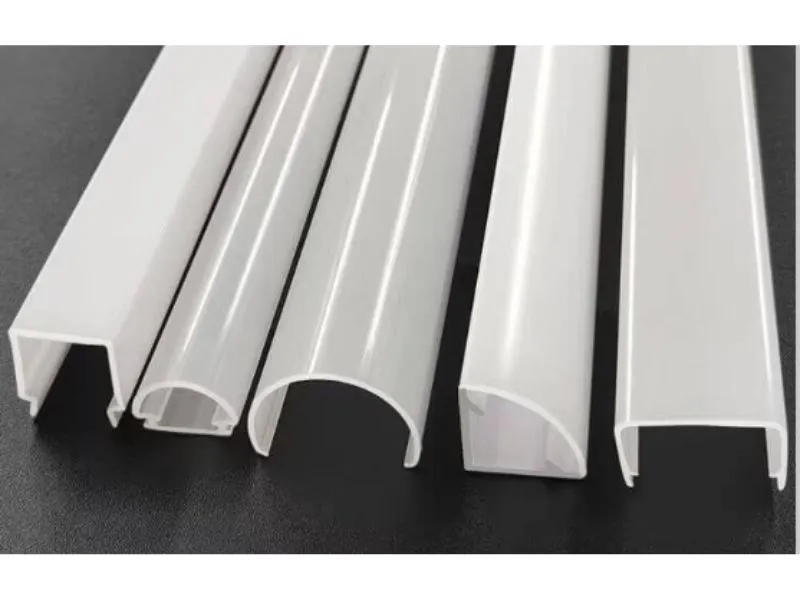

Technologie de calibrage et de découpage de haute précision : La clé de la perfection

Nous savons que la filière est au cœur de l'extrusion des profilés. Notre expertise réside dans la conception et la collaboration de filières et de calibrateurs de haute précision pour les formes complexes de LED. Cela garantit des dimensions précises, des détails nets et des surfaces lisses, même pour des conceptions complexes à cavités multiples ou coextrudées.

Équipement en aval pour les profils délicats : Manipulation soigneuse

Nos équipements en aval, y compris les tables de calibrage sous vide, les unités de tirage et les découpeurs, sont conçus pour une manipulation soigneuse des profils optiques afin d'éviter les rayures, les déformations et les contraintes. Des options de pelliculage protecteur sont disponibles pour préserver la qualité de la surface.

Séchage et prétraitement des matériaux : Garantir un traitement optimal

Le PC et le PMMA sont hygroscopiques et nécessitent un séchage complet avant l'extrusion afin d'éviter les défauts tels que les bulles ou les stries argentées. Nos solutions intègrent des systèmes de séchage efficaces pour préparer les matériaux de manière optimale en vue d'une production de profilés sans faille.

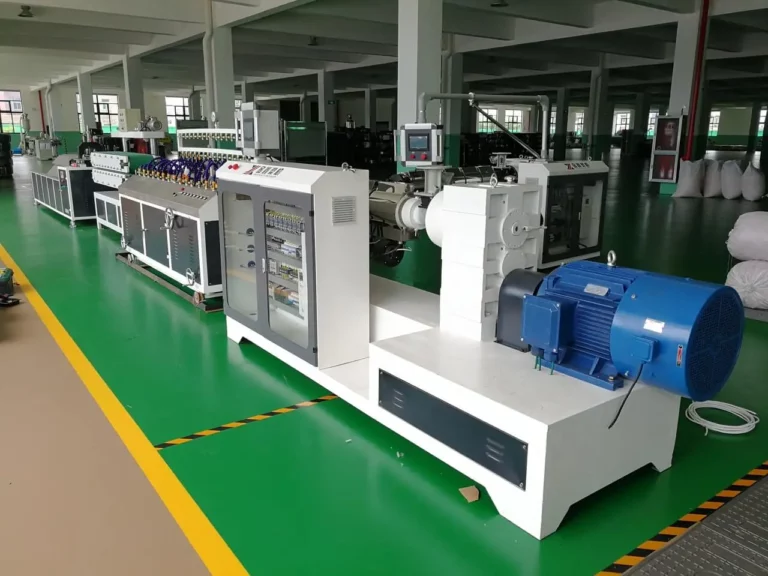

Système de contrôle avancé avec surveillance des processus

Un système de commande PLC intelligent permet de contrôler avec précision tous les paramètres, de la température à la vitesse. La surveillance en temps réel permet de maintenir la stabilité du processus, ce qui est essentiel pour obtenir une qualité constante dans les longues séries de production de profilés optiques.

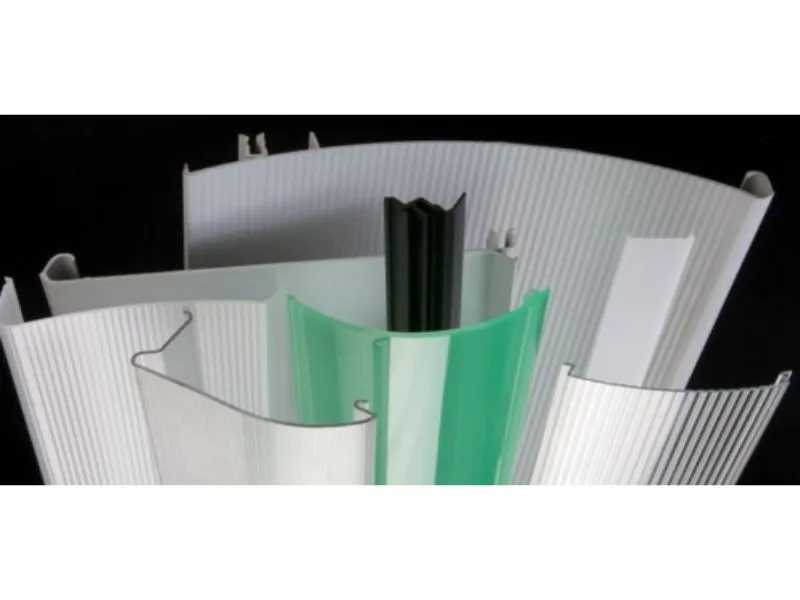

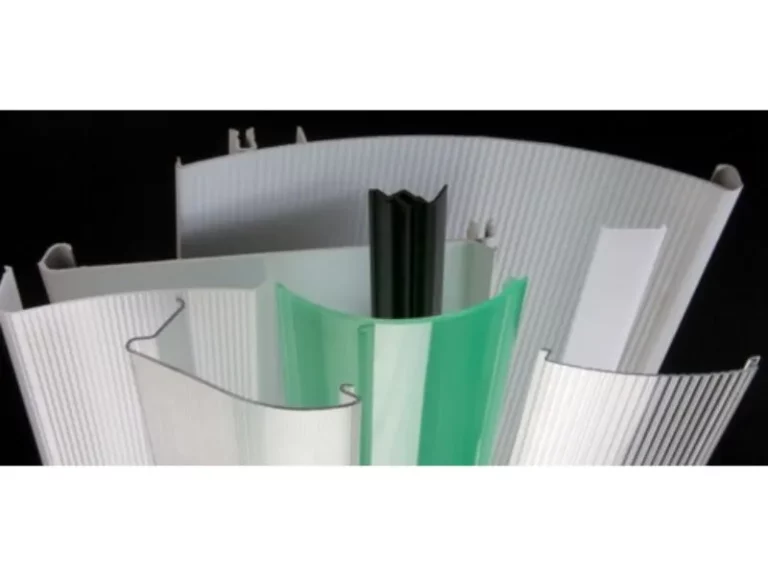

Capacités de co-extrusion pour une meilleure fonctionnalité

Explorez les profils LED multicouches ou multicolores grâce à notre technologie de coextrusion. Combinez les matériaux pour obtenir des effets optiques spécifiques, améliorer la durabilité ou intégrer différentes fonctionnalités dans un seul profil.

Discutez de votre projet

Vous voulez en savoir plus ? Découvrez notre machine d'extrusion de profilés LED en PC PMMA ci-dessous

Votre machine d'extrusion de profilés LED en PMMA PC : Réponses aux questions clés

Peut vous aider à en savoir plus

Nous avons un profilé LED unique en son genre. Comment votre solution de machine d'extrusion de profilés LED en PC PMMA peut-elle nous aider ?

C'est précisément là que nous excellons. Nous travaillons en partenariat avec des clients qui ont des conceptions innovantes. Vous nous fournissez le concept et les dessins du profil, et notre équipe, ainsi que des fabricants de filières expérimentés, travailleront en étroite collaboration avec vous pour développer la filière optimale et un processus d'extrusion complet.

Nous vous guidons dans la sélection des matériaux et des paramètres de processus pour transformer votre vision en un produit physique de haute qualité. Notre objectif est d'aboutir à une collaboration fructueuse.

Quels sont les défis courants liés à l'extrusion de PC et de PMMA pour les applications optiques, et comment votre équipement y répond-il ?

Les principaux défis sont la dégradation des matériaux (jaunissement, taches noires), l'obtention d'une clarté/transparence élevée et le maintien de tolérances dimensionnelles étroites.

Nos machines répondent à ces besoins :

1) Géométrie spéciale de la vis et contrôle de la température pour minimiser le cisaillement et éviter la surchauffe.

2) Des matrices de haute précision et un calibrage minutieux pour des profils précis.

3) Des systèmes de pré-séchage robustes pour éliminer les défauts liés à l'humidité. Cela permet de produire des profils LED optiquement clairs et dimensionnellement stables.

Comment protégez-vous nos dessins et modèles exclusifs lorsque vous discutez d'un projet de machine d'extrusion de profilés LED en PMMA ?

Nous respectons pleinement la confidentialité des conceptions pour tout projet de machine d'extrusion de profilés LED en PC PMMA. Nous signons volontiers des accords de confidentialité avant toute discussion technique détaillée sur votre **machine d'extrusion de profilés LED en PC PMMA** ou sur la conception de vos filières. La confiance est primordiale.

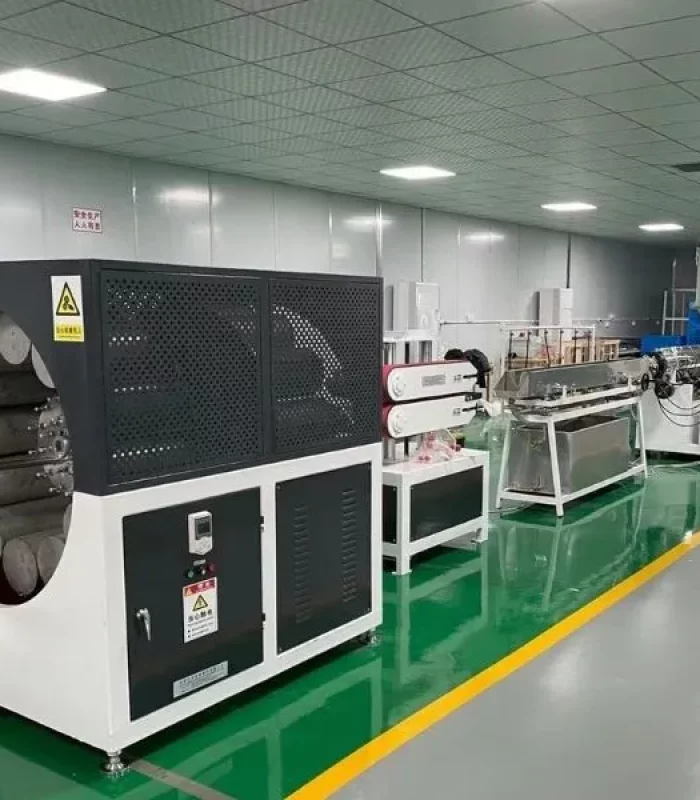

À propos de JINXIN Plastic Machinery

Depuis 2012

Nous sommes honnêtes et fiables, et nous fournissons des équipements rentables pour votre usine.

En choisissant notre équipement, vous vous associez à un fournisseur qui s'engage à résoudre vos problèmes grâce à des solutions de haute qualité, rentables et conçues par des experts. Nous garantissons la fiabilité et les performances de tous les produits que nous proposons, afin que votre investissement produise les résultats dont vous avez besoin pour que votre entreprise prospère.

Une qualité éprouvée

Plus d'une décennie d'expérience et de retour d'information de la part des clients garantit que les machines que nous sélectionnons offrent une durabilité à long terme et des performances fiables.

Valeur exceptionnelle

Nous fournissons des équipements de haute qualité à des prix compétitifs, maximisant ainsi votre investissement grâce à des performances de premier ordre.

Un soutien fiable

Une assistance et un service complets garantissent un fonctionnement sans heurts et des temps d'arrêt minimaux, ce qui permet de maintenir une productivité optimale.

Ce que disent nos clients

Nos étonnants fournisseurs

SOLUTIONS D'EXTRUSION

Adresse électronique

sales@jfextruder.com

Adresse de l'usine

No. 31 Yuci Rd., Yuyao, Ningbo City, Zhejiang Province, China