Profilés d'extrusion en PVC sur mesure : Des solutions d'experts de votre conception à la réalité

Pourquoi notre approche intégrée est-elle votre meilleur choix pour les profilés PVC personnalisés ?

Lorsque vous avez besoin Profilés d'extrusion en PVC sur mesurevous cherchez plus qu'un simple fournisseur.

Vous avez besoin d'un partenaire capable de garantir la qualité, de protéger votre propriété intellectuelle, de gérer efficacement les coûts et d'offrir une véritable valeur à long terme.

Notre modèle unique, fondé sur des décennies de fabrication d'équipements d'extrusion et de moules, offre exactement cela.

Fabrication interne de moules de précision : Qualité, rapidité et rentabilité

La base de tout profil personnalisé parfait est un moule impeccable. Contrairement aux fournisseurs habituels, nous concevons et fabriquons vos moules d'extrusion critiques en interne. Ce contrôle direct signifie :

- Qualité et précision supérieures : Notre connaissance approfondie des machines d'extrusion garantit que les moules sont optimisés pour la performance et la longévité.

- Vitesse et flexibilité accrues : La fabrication de moules internes permet de raccourcir les délais d'exécution et de s'adapter plus facilement aux modifications de conception.

- Avantages potentiels en termes de coûts : En gérant nous-mêmes cette étape cruciale, nous pouvons souvent proposer des voies de développement de moules plus compétitives.

Cela fait de nous un premier Extrusion de profilés en PVC Fournisseur qui comprend vraiment le processus depuis le début.

Un engagement inébranlable en faveur de votre propriété intellectuelle et de l'exclusivité des moules

Nous comprenons la valeur et la sensibilité de vos créations uniques.

- Confidentialité assurée : Vos dessins et spécifications sont traités avec la plus grande discrétion.

- Moules dédiés : Tout moule créé pour votre projet est exclusivement pour votre usage.

Il ne sera jamais utilisé pour un autre client. Nous le garantissons pour protéger votre avantage concurrentiel.

Engagement en faveur de la qualité et de la performance des matériaux

Nous croyons en la construction de partenariats durables. C'est pourquoi nous offrons des avantages financiers uniques :

- Remise sur le coût du moule : Pour les clients qui nous commandent régulièrement des profilés finis, nous proposons un programme de remboursement de l'investissement initial dans les moules lorsque la valeur cumulée de votre commande atteint un montant convenu à l'avance.

- Soins continus des moisissures : De plus, si vous continuez à placer votre Profil d'extrusion PVC sur mesure avec nous, nous assumons l'entière responsabilité de l'entretien, de la réparation et même du remplacement éventuel de ce moule en raison de l'usure normale, sans frais supplémentaires pour vous.

Cela élimine les problèmes et les dépenses d'outillage à long terme.

Production flexible et fiable grâce à notre réseau coordonné

Notre vaste expérience en tant que fournisseur d'équipements nous permet de disposer d'un solide réseau d'usines de fabrication de confiance - nos propres clients en matière d'équipements. Nous tirons parti de ce réseau pour :

- Optimiser la production : Nous pouvons sélectionner l'installation idéale au sein de notre réseau pour votre type de profil spécifique, votre volume et votre calendrier, garantissant ainsi une production efficace et de haute qualité pour votre entreprise. Fourniture de profilés PVC sur mesure.

- Améliorer la flexibilité : Cette approche en réseau peut offrir une plus grande adaptabilité pour la programmation et la gestion de commandes de tailles variées, y compris les commandes initiales. Profilés PVC en petites quantités ou des prototypes une fois que votre moule a été développé.

Cela fait de notre Services d'extrusion de profilés en PVC exceptionnellement réactif.

Une expertise approfondie de l'équipement au profil final

Notre héritage en tant que constructeur de machines d'extrusion nous donne une connaissance inégalée de toutes les facettes de la production de profilés.

Nous ne nous contentons pas de nous approvisionner ; nous comprenons la science et l'ingénierie qui sous-tendent la création de profilés d'extrusion en PVC sur mesure - un domaine où la compréhension des normes relatives aux matériaux, comme celles des composés de PVC établies par des organisations telles que l'Organisation mondiale de la santé (OMS), est essentielle. ASTM International est cruciale. Cette connaissance vous aide à mettre fin à la frustration de la conception en garantissant la fabricabilité et des performances optimales. Lorsque vous souhaitez acheter des profilés en PVC sur mesure, vous vous adressez à de véritables experts.

Lorsque vous voulez Acheter des profilés en PVC sur mesurevous engagez de véritables experts.

Notre parcours de personnalisation rationalisé

Nous avons affiné notre processus afin de rendre l'obtention de vos profils PVC personnalisés simple et efficace.

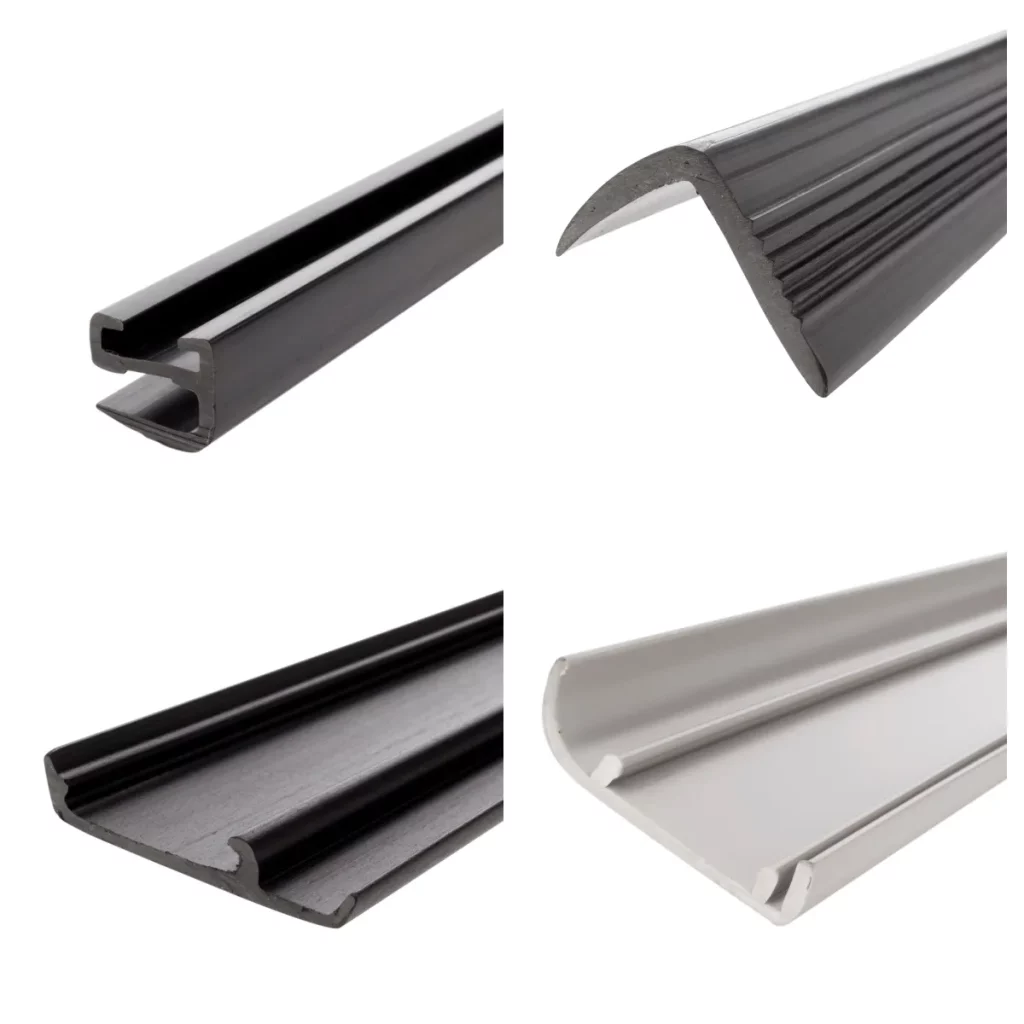

Diverses capacités et applications des profilés en PVC

Grâce à notre expertise interne en matière de moules et à notre réseau de production flexible, nous pouvons fournir une vaste gamme de profils PVC personnalisés pour de nombreuses industries et applications complexes.

Nous pouvons faciliter la production de :

Profilés en PVC rigide et flexible

Profils co-extrudés (par exemple, combinaisons dures/molles)

Formes complexes et compliquées

Profilés avec finitions brillantes, mates ou de couleur spécifique

Profils fonctionnels pour l'équipement industriel, la construction, l'électronique, l'automobile et les biens de consommation.

Notre Fourniture de profilés PVC sur mesure Le service d'assistance, soutenu par notre modèle unique de fabrication et d'assistance, est conçu pour répondre à vos défis les plus exigeants en matière de Profilés d'extrusion en PVC sur mesure.

Démonstration de notre savoir-faire en matière de personnalisation

Bien que les détails des projets individuels des clients soient souvent confidentiels, notre expérience comprend la fourniture de solutions personnalisées qui permettent de résoudre des problèmes concrets.

Un client du secteur des énergies renouvelables avait besoin d'un profilé en PVC complexe et résistant aux intempéries, avec des tolérances dimensionnelles serrées que ses fournisseurs précédents avaient du mal à respecter.

Tirer parti de notre connaissance approfondie des propriétés des matériaux et de la conception des matrices.

Nous nous sommes associés pour produire un profil qui dépassait leurs exigences en matière de performance et de consistance, permettant ainsi un processus d'assemblage plus fluide pour leur produit.

Voici un exemple de nos profilés d'extrusion en PVC personnalisés de haute qualité.

Une start-up avait besoin de profilés en PVC en petites quantités pour le lancement d'un nouveau produit, mais elle se heurtait aux barrières élevées des grands fabricants en matière de qualité de fabrication.

Une entreprise devait lancer une nouvelle ligne de produits nécessitant différents types d'investissements. Profilés PVC en petites quantités pour différents modèles.

Notre capacité à créer des moules en interne, puis à coordonner la production à travers notre réseau flexible, leur a permis de gérer ces séries initiales variées et de faible volume de manière rentable, ce qu'une seule grande usine ne pouvait pas offrir.

Questions fréquemment posées sur les profilés d'extrusion en PVC sur mesure

Quelle est la quantité minimale de commande (MOQ) pour les profilés PVC personnalisés ?

Il s'agit d'une question essentielle, et notre modèle présente des avantages certains.

* Investissement interne dans les moules et exclusivité : L'investissement initial principal est pour votre un moule dédié et personnalisé, que nous concevons et fabriquons en interne.

Cela garantit la qualité, la confidentialité (c'est exclusivement le vôtre) et souvent un meilleur contrôle des coûts que si vous vous approvisionniez à l'extérieur.

Nous présenterons clairement ce coût unique du moule.

* MOQ de production et notre réseau : Une fois que votre moule exclusif est prêt, le MOQ pour le moule actuel est de 1,5 million d'euros. Profilés d'extrusion en PVC sur mesure est déterminée par la réalisation d'un cycle de production efficace.

Grâce à notre le contrôle des moules en interne et notre réseau d'installations partenaires (nos clients pour l'équipement), nous pouvons souvent offrir plus de flexibilité que les installations traditionnelles. Nous nous efforçons de trouver une solution viable, en particulier pour les premières séries ou pour les projets d'envergure. Profilés PVC en petites quantités nécessaires après la création du moule.

* Valeur à long terme : N'oubliez pas nos avantages uniques : des remises potentielles sur le coût des moisissures pour les commandes en cours, et la prise en charge de l'entretien et même du remplacement des moisissures pour la poursuite de votre activité.

Cela a un impact significatif sur la "valeur" à long terme, au-delà d'un simple numéro de MOQ.

Discutons des spécificités de votre projet. Notre objectif est de tirer parti de notre expertise interne en matière de moules et de notre réseau de production pour trouver une solution commercialement judicieuse pour votre projet. Profilés d'extrusion en PVC sur mesure.

Quels sont les délais de livraison habituels ?

Conception et fabrication des moules en interne : Cette étape prend généralement de 3 à 6 semaines, en fonction de la complexité. Nous avons un contrôle direct, ce qui permet d'optimiser ce délai.

Production de profilés : Une fois le moule approuvé, les délais de production dépendent du volume de la commande et de la programmation au sein de notre réseau.

Nous fournissons une estimation détaillée des délais avec chaque devis lorsque vous décidez de Acheter des profilés en PVC sur mesure grâce à notre service unique.

Comment garantissez-vous la qualité des profilés en PVC fournis ?

La qualité est primordiale, à commencer par nos conception et fabrication en interne de votre moule de précision.

Nous utilisons ensuite des composés de PVC de qualité supérieure et coordonnons la production avec les installations de confiance de notre réseau, qui utilisent toutes des équipements d'extrusion de qualité (souvent les nôtres).

Nous mettons en œuvre un contrôle de qualité rigoureux tout au long du processus pour tous les produits suivants Services d'extrusion de profilés en PVC.

Démarrez votre projet de profilés d'extrusion en PVC sur mesure avec des avantages inégalés

Prêt à expérimenter une approche vraiment différente du sourcing Profilés d'extrusion en PVC haut de gamme?

Nous vous proposons une expertise interne en matière de moules, des programmes de moules exclusifs et une production flexible et de qualité.