Machine d'extrusion de tubes à immersion de haute précision

Demande de devis

Calculer le retour sur investissement de la machine d'extrusion de tubes à immersion

Maîtriser la production de tubes à immersion : Notre technologie d'extrusion

Pour les entreprises qui ont besoin de tubes plongeurs de haute qualité pour l'emballage, il est essentiel de connaître l'équipement de fabrication adéquat. Cette section explique comment notre machine d'extrusion de tubes plongeurs offre la précision, la cohérence et l'efficacité dont vous avez besoin.

Nous nous concentrons sur les avantages directs : des machines durables qui produisent des tubes répondant exactement aux spécifications, minimisant les déchets et maximisant votre production de produits prêts à être commercialisés. Découvrez les composants qui font de notre solution un investissement intelligent.

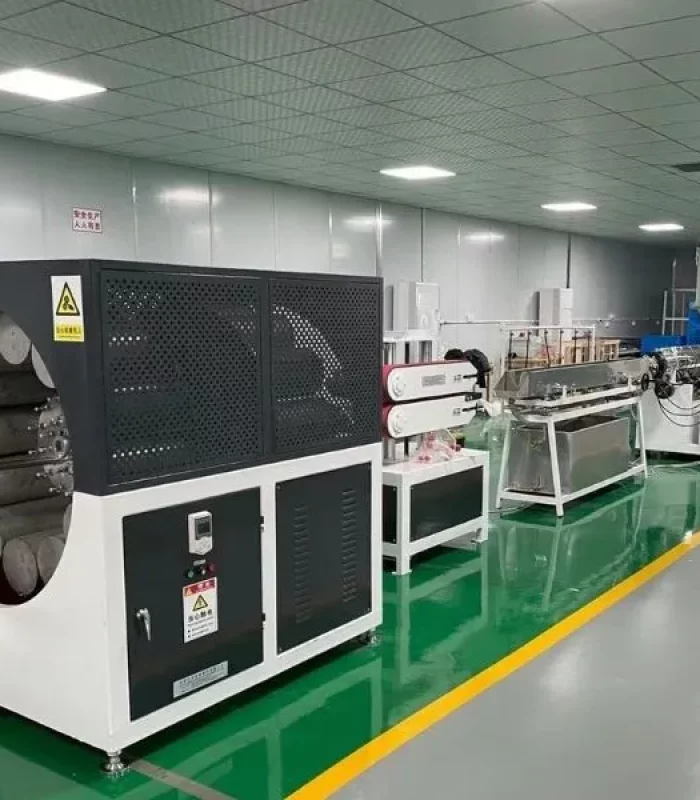

Extrudeuse de précision à une vis : Distribution constante de la matière fondue

Cette extrudeuse, qui constitue le cœur de la ligne d'extrusion de tubes de trempage, est spécifiquement optimisée pour LDPE et PP.

Ces polymères sont choisis pour leurs excellentes propriétés de production de tubes à immersion durables et précis.

La conception de notre extrudeuse garantit une fusion uniforme et une production stable de ces matériaux, ce qui est essentiel pour les applications à parois minces, et favorise une excellente plastification pour un flux de matériaux constant.

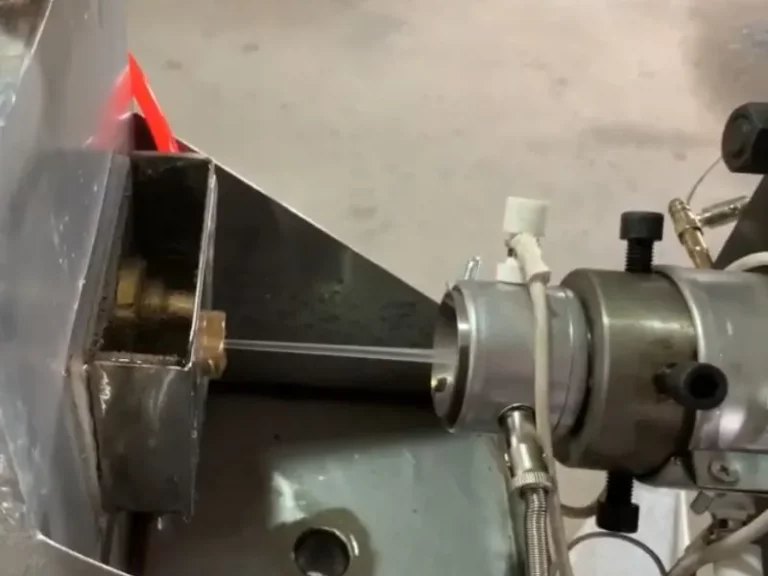

Tête de filière et outillage spécialisés : Formage de tubes sans défaut

Notre tête de filière sur mesure et notre outillage de précision sont conçus pour les petits diamètres et les tolérances serrées exigés pour les tubes plongeurs.

Cela garantit des dimensions de tube précises, des surfaces lisses et une épaisseur de paroi constante, ce qui est essentiel pour le fonctionnement des pompes et des pulvérisateurs.

Réservoir de calibrage et de refroidissement sous vide : Solidifier la perfection

Un système efficace de calibrage sous vide et de refroidissement à l'eau stabilise rapidement le tube extrudé, garantissant qu'il conserve sa forme circulaire et son diamètre précis.

Ceci est essentiel pour produire des tubes de haute qualité, droits et prêts à être assemblés.

Une sortie de ceinture stable : une traction douce et précise

L'unité de traction à courroie fournit une force de traction régulière et constante, parfaitement synchronisée avec l'extrudeuse.

Cela permet d'éviter la déformation des délicats tubes de trempage et de maintenir des dimensions uniformes tout au long du cycle de production.

Coupeur de précision à grande vitesse : Des coupes nettes, à chaque fois

Notre unité de coupe est conçue pour couper à grande vitesse et avec précision des tubes de petit diamètre, afin d'obtenir des extrémités propres et sans bavures.

Les tubes de trempage sont ainsi prêts à être utilisés immédiatement dans l'assemblage, sans autre traitement.

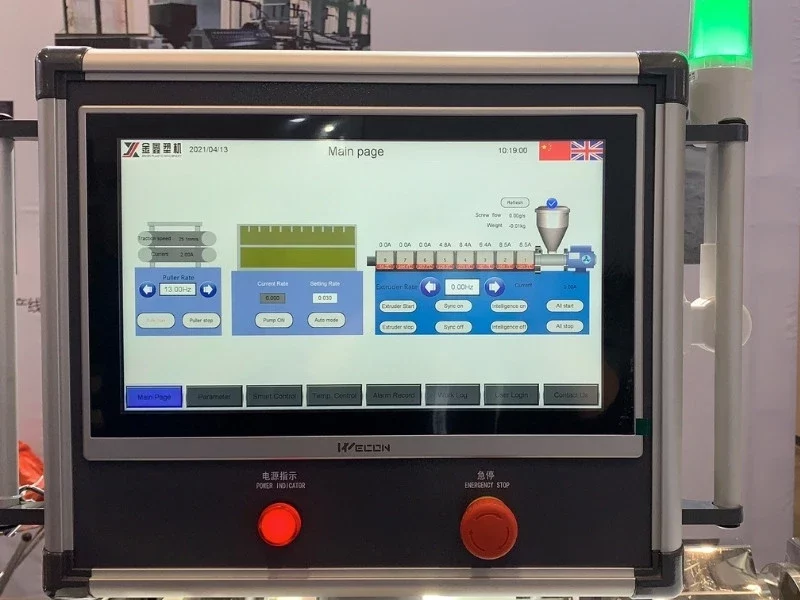

Système de contrôle PLC convivial : Fonctionnement sans effort

L'ensemble de la ligne est géré par un système de contrôle PLC intuitif doté d'une interface à écran tactile et d'un système multilingue.

Il permet un paramétrage facile, une surveillance du processus en temps réel et des ajustements rapides, ce qui simplifie l'exploitation et maximise le temps de fonctionnement.

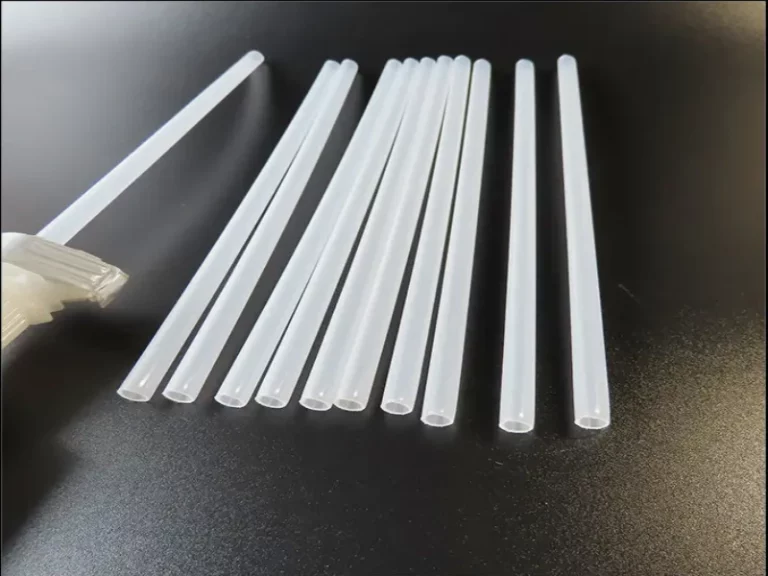

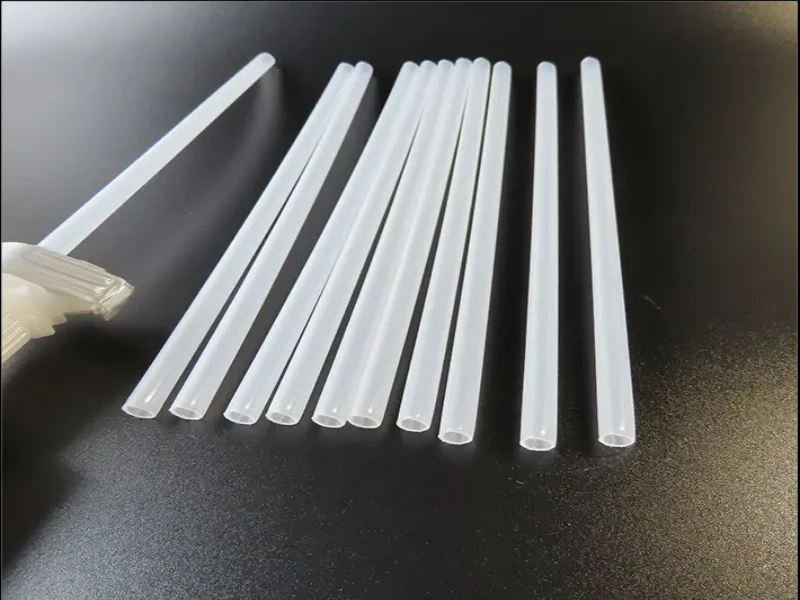

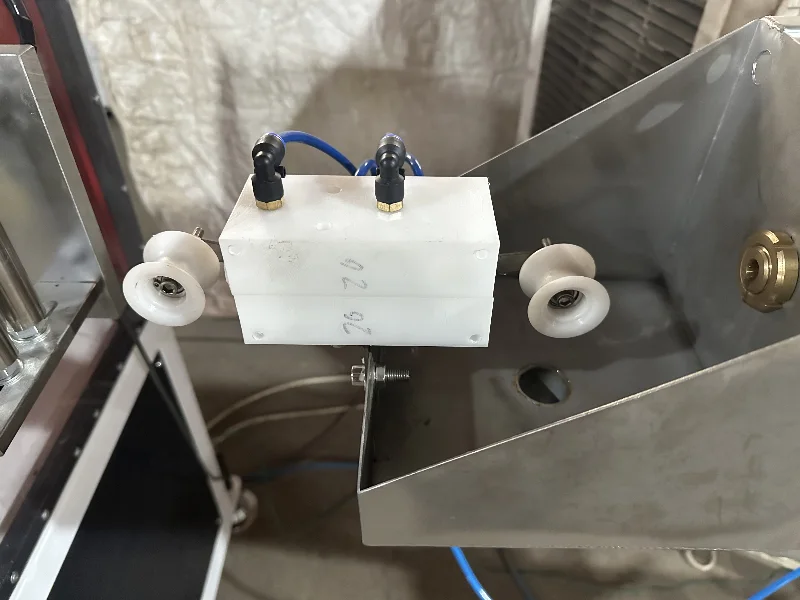

Précision et soin dans les moindres détails

Notre machine d'extrusion de tubes plongeurs témoigne d'un haut niveau de professionnalisme et d'une conception réfléchie, notamment grâce à l'ajout d'un petit dispositif de soufflage d'air à l'extrémité du réservoir d'eau. Placé juste avant que les tuyaux n'entrent dans l'unité de transport, ce dispositif sèche rapidement l'eau résiduelle, ce qui garantit que les tuyaux sont exempts d'humidité.

Cette opération a deux objectifs principaux : elle améliore la forme finale du tuyau pour une qualité supérieure et empêche l'eau de couler sur le sol de l'usine, ce qui réduit le risque de glissade et maintient un espace de travail plus sûr et plus propre. Ce petit détail, qui a pourtant un impact, souligne notre engagement en faveur de la précision et de l'attention portée aux besoins de nos clients.

Une qualité éprouvée

Plus d'une décennie d'expérience et de retour d'information de la part des clients garantit que les machines que nous sélectionnons offrent une durabilité à long terme et des performances fiables.

Valeur exceptionnelle

Nous fournissons des équipements de haute qualité à des prix compétitifs, maximisant ainsi votre investissement grâce à des performances de premier ordre.

Un soutien fiable

Une assistance et un service complets garantissent un fonctionnement sans heurts et des temps d'arrêt minimaux, ce qui permet de maintenir une productivité optimale.

Ce que disent nos clients

Nos étonnants fournisseurs

Réponses à vos questions : Machine d'extrusion de tubes de trempage

Peut vous aider à en savoir plus

Quelle est la gamme typique de diamètres et de tolérances que votre machine d'extrusion de tubes de trempage peut atteindre ? Ce point est essentiel pour l'assemblage de nos pompes.

Notre machine est spécialement conçue pour les tubes de petit diamètre, généralement compris entre 1,5 mm et 8 mm de diamètre extérieur, avec un excellent contrôle des tolérances, souvent de l'ordre de +/- 0,1 mm, en fonction du matériau et de la taille du tube.

Nous comprenons qu'un ajustement précis est crucial, et notre système est conçu pour assurer cette cohérence et une intégration transparente avec les mécanismes de votre pompe et de votre pulvérisateur.

Nous devons produire des tubes de trempage à partir de LDPE et de PP. Est-il facile de changer de matériau sur votre machine et cela affecte-t-il les performances ?

Le passage du LDPE au PP est simple. Bien qu'une certaine purge soit nécessaire, la conception de notre vis et de notre tête de filière facilite un changement de matériau efficace. Nous fournissons des directives claires pour ce processus.

Les performances restent optimales pour les deux matériaux, car les profils de chauffage et la géométrie des vis de la machine sont conçus pour gérer efficacement leurs caractéristiques de traitement spécifiques.

Comment votre machine assure-t-elle la rectitude des tubes d'immersion ? Les tubes courbés posent des problèmes sur nos lignes d'assemblage.

La rectitude du tube est un élément clé. Notre système garantit cette rectitude grâce à une combinaison de facteurs : une conception optimisée de la filière pour un flux régulier du matériau, un calibrage sous vide précis et stable qui forme et soutient correctement le tube pendant le refroidissement, et un système de tirage et de coupe correctement aligné.

Cela minimise les contraintes internes qui peuvent conduire à une flexion, ce qui garantit que vous recevrez des tubes droits prêts à être assemblés sans problème.

SOLUTIONS D'EXTRUSION

Adresse électronique

sales@jfextruder.com

Adresse de l'usine

No. 31 Yuci Rd., Yuyao, Ningbo City, Zhejiang Province, China