La industria del plástico se enfrenta a una presión cada vez mayor para ofrecer soluciones sostenibles y eficientes en medio de una normativa cada vez más estricta y un aumento de los costes de los materiales. Muchos fabricantes luchan por superar estos retos sin perder competitividad. CHINAPLAS 2025 ofreció una plataforma crucial para descubrir tecnologías innovadoras que abordan exactamente estos problemas.

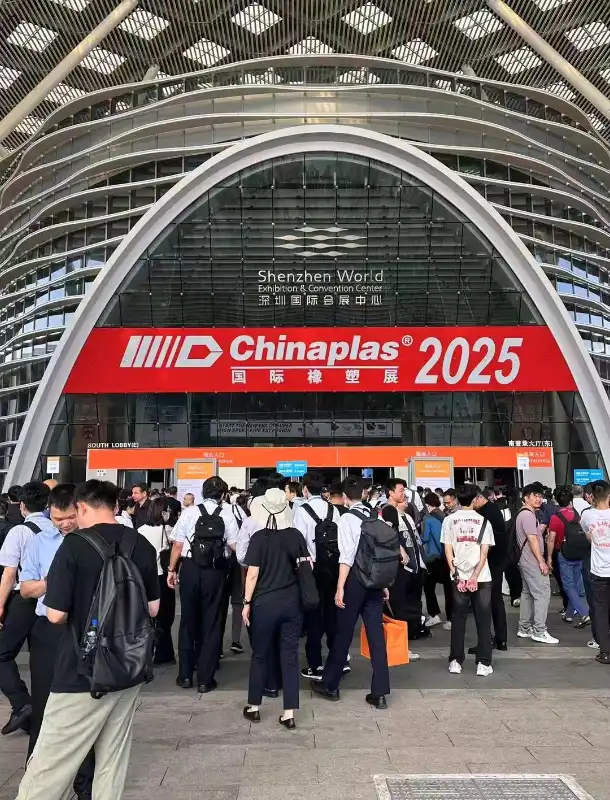

CHINAPLAS 2025, celebrado del 15 al 18 de abril en el Centro Mundial de Exposiciones de Shenzhen, mostró innovaciones transformadoras en las industrias del plástico y el caucho. El evento puso de relieve soluciones sostenibles, avances en la fabricación digital y nuevos materiales que están transformando la forma en que los fabricantes afrontan los retos de la producción.

Revisión de CHINAPLAS 2025: ¿Cómo evoluciona la industria del plástico a través de la innovación? 1

Revisión de CHINAPLAS 2025: ¿Cómo evoluciona la industria del plástico a través de la innovación? 1

Como asistentes a este prestigioso evento, Jinxin Plastic Machinery fue testigo de primera mano de cómo está evolucionando la industria. La exposición atrajo a más de 281.206 visitantes profesionales, incluidos 68.542 asistentes internacionales de más de 171 países y regiones. Exploremos los puntos clave y las innovaciones que dominaron la feria de este año.

¿Qué ha hecho de CHINAPLAS 2025 un acontecimiento crucial para las industrias del plástico y el caucho?

Las empresas de los sectores del plástico y el caucho buscan constantemente formas de seguir siendo competitivas en un mercado en rápida evolución. Encontrar innovaciones relevantes que aborden los retos del mundo real puede resultar abrumador. CHINAPLAS 2025 ofreció una visión completa de tecnologías probadas con aplicaciones prácticas.

CHINAPLAS 2025 se distinguió por centrarse en cuatro temas críticos: Economía Circular, Digitalización, Materiales Innovadores y Tecnología de Alta Gama Made in China. Estas áreas abordaron directamente los retos más acuciantes a los que se enfrentan los fabricantes hoy en día, desde los mandatos de sostenibilidad hasta las exigencias de eficiencia.

Revisión de CHINAPLAS 2025: ¿Cómo evoluciona la industria del plástico a través de la innovación? 2

Revisión de CHINAPLAS 2025: ¿Cómo evoluciona la industria del plástico a través de la innovación? 2

Escala y diversidad sin precedentes

La edición 2025 de CHINAPLAS subió realmente el listón de las exposiciones del sector. Con una superficie de 380.000 metros cuadrados, el evento contó con más de 4.500 expositores que presentaron más de 3.800 máquinas de última generación. Esta enorme escala proporcionó oportunidades sin precedentes para compararse con los líderes de la industria e identificar las tendencias emergentes.

Lo que hizo especialmente valiosa la exposición de este año fue la diversidad de soluciones presentadas. Desde empresas multinacionales a proveedores especializados como Maquinaria de plástico JinxinLas empresas de todo el espectro mostraron sus enfoques ante retos comunes de la industria.

La organización de la exposición en zonas especializadas facilitó la navegación a los asistentes con intereses específicos. Por ejemplo, las empresas centradas en la sostenibilidad podían explorar las zonas dedicadas a las tecnologías de reciclado, los plásticos reciclados, los bioplásticos y los aditivos ecológicos, que en conjunto contaban con más de 300 expositores especializados.

Según la estadísticas oficiales de CHINAPLASEn la edición de este año se registró una importante presencia internacional, con visitantes procedentes de más de 171 países y regiones, lo que subraya la importancia mundial de la exposición. Esta presencia internacional creó valiosas oportunidades de establecer contactos para las empresas que buscan ampliar su alcance de mercado más allá de las fronteras regionales.

Plataformas de intercambio de conocimientos

Además de la exposición, CHINAPLAS 2025 ofreció numerosos actos paralelos diseñados para facilitar el intercambio de conocimientos y la colaboración empresarial. Entre ellos:

- Charlas técnicas con expertos del sector sobre las tecnologías más avanzadas

- El Foro de Envases de Plástico Sostenibles aborda los retos críticos de la sostenibilidad de los envases

- InnoGreen Hub muestra soluciones medioambientales

- Rutas guiadas especializadas por la exposición centradas en industrias o tecnologías concretas

Estas plataformas de intercambio de conocimientos ofrecieron valiosas perspectivas sobre las tendencias del mercado, la evolución de la normativa y las innovaciones tecnológicas que configurarán el futuro de las industrias del plástico y el caucho. Para los fabricantes de equipos, estas sesiones ofrecieron información crucial para la planificación estratégica y el desarrollo de productos.

¿Cómo influyeron las tendencias de sostenibilidad en CHINAPLAS 2025 en los planteamientos de fabricación?

La preocupación por el medio ambiente sigue siendo un reto para la industria del plástico, y los fabricantes se enfrentan a una presión cada vez mayor por parte de las autoridades reguladoras y los consumidores. Muchas empresas luchan por equilibrar los objetivos de sostenibilidad con la eficiencia de la producción y los costes. CHINAPLAS 2025 presentó soluciones prácticas a esta ecuación aparentemente imposible.

La sostenibilidad fue el tema dominante en CHINAPLAS 2025, con innovaciones centradas en los principios de la economía circular, las tecnologías de reciclaje y los materiales ecológicos. Estos avances están cambiando radicalmente la forma de diseñar y utilizar los equipos, dando prioridad a la eficiencia de los recursos y la reducción de residuos.

Soluciones de economía circular

El concepto de economía circular ocupó un lugar central en CHINAPLAS 2025, con numerosos expositores que mostraron sistemas de fabricación de circuito cerrado. Estas soluciones pretenden minimizar los residuos manteniendo los materiales en uso el mayor tiempo posible mediante el reciclaje, la renovación y la refabricación.

Para los fabricantes de equipos, esta tendencia tiene implicaciones significativas. En Jinxin, hemos estado observando de cerca estos desarrollos, reconociendo la importancia de diseñar nuestras líneas de extrusión para procesar eficazmente los materiales reciclados sin comprometer el rendimiento ni la calidad. En CHINAPLAS hemos sido testigos de varias innovaciones en este campo:

| Tecnología | Aplicación | Beneficios |

|---|

| Sistemas avanzados de filtración | Tratamiento de materiales reciclados contaminados | Mejora de la calidad de la producción y reducción de los tiempos de inactividad |

| Coextrusión multicapa | Incorporación de contenido reciclado en las capas intermedias | Mantiene la calidad de la superficie al tiempo que aumenta el contenido reciclado |

| Sistemas de calefacción energéticamente eficientes | Reducir el consumo de energía en la transformación | Menores costes de explotación, menor huella de carbono |

| Manipulación inteligente de materiales | Optimización de la mezcla y alimentación de materiales | Calidad constante con contenido reciclado variable |

El Reglamento de la Unión Europea sobre envases y residuos de envases (PPWR) y las restricciones sobre PFAS han acelerado la demanda de alternativas sostenibles, como se destaca en el Informe de la Asociación de la Industria del Plástico. Esta presión normativa quedó patente en las soluciones presentadas en CHINAPLAS, y muchos expositores abordaron específicamente el cumplimiento de estas normas emergentes.

Revisión de CHINAPLAS 2025: ¿Cómo evoluciona la industria del plástico a través de la innovación? 3

Revisión de CHINAPLAS 2025: ¿Cómo evoluciona la industria del plástico a través de la innovación? 3

Revolución de los materiales biológicos

En CHINAPLAS 2025, los polímeros de origen biológico se convirtieron en protagonistas, y numerosos expositores presentaron materiales derivados de recursos renovables. Estas innovaciones son especialmente relevantes para los fabricantes de equipos, ya que el procesamiento de estos materiales a menudo requiere maquinaria especializada o modificaciones en los equipos existentes.

En Jinxin hemos seguido estos acontecimientos con interés, reconociendo la creciente importancia de compatibilidad de los equipos con los materiales de origen biológico. CHINAPLAS aportó valiosos conocimientos sobre los últimos avances en este campo en rápida evolución.

La exposición puso de relieve varias tendencias clave en materiales de origen biológico para diversas aplicaciones:

- Mayor estabilidad al calor en las fórmulas de PLA (ácido poliláctico), lo que amplía sus aplicaciones potenciales.

- Polietileno de origen biológico con prestaciones equivalentes a las del PE convencional

- Nuevos compuestos a base de celulosa más procesables

- Aditivos biodegradables que mejoran el perfil medioambiental de los plásticos convencionales

Estas innovaciones están abriendo nuevas posibilidades para el desarrollo de productos sostenibles en diversas industrias, desde el envasado hasta la construcción.

Las operaciones de producción tradicionales suelen adolecer de ineficiencias, incoherencias en la calidad y tiempos de inactividad excesivos. Los fabricantes tienen dificultades para optimizar los procesos sin datos en tiempo real ni capacidad predictiva. Las tecnologías de transformación digital presentadas en CHINAPLAS 2025 ofrecen soluciones convincentes a estos retos persistentes.

CHINAPLAS 2025 puso de relieve avances significativos en tecnologías de fabricación digital, como líneas de producción integradas en IoT, optimización de procesos impulsada por IA y sistemas de supervisión basados en la nube. Estas innovaciones están impulsando avances en la eficiencia de la producción y la precisión de los productos, al tiempo que reducen el impacto medioambiental.

Soluciones de fabricación inteligente

Los principios de la Industria 4.0 ocuparon un lugar destacado en CHINAPLAS 2025, con numerosos expositores que demostraron cómo las tecnologías digitales pueden transformar las operaciones tradicionales. Estas soluciones de fabricación inteligente integran sensores, análisis de datos y automatización para crear sistemas de producción más eficientes y con mayor capacidad de respuesta.

En Jinxin, hemos seguido de cerca estos avances tecnológicos, reconociendo su importancia para el futuro de la tecnología. equipos de extrusión de plásticos. La exposición proporcionó información valiosa sobre los últimos avances en este campo en rápida evolución.

Entre las principales tecnologías de transformación digital expuestas en CHINAPLAS figuran:

| Tecnología | Aplicación | Beneficios |

|---|

| Redes de sensores IoT | Control en tiempo real de los parámetros de procesamiento | Detección inmediata de desviaciones del proceso |

| Optimización de procesos mediante IA | Ajuste automático de los parámetros de producción | Calidad constante, menor desperdicio de material |

| Simulación de gemelos digitales | Modelado virtual de procesos de fabricación | Configuración más rápida, menos pruebas |

| Sistemas de mantenimiento predictivo | Control de los indicadores de salud de los equipos | Reducción de los tiempos de inactividad y prolongación de la vida útil de los equipos |

| Gestión de la producción basada en la nube | Control centralizado de varias líneas de producción | Mejor asignación de recursos, planificación de la producción |

Según Estadísticas de implantación de la Industria 4.0Las empresas que aplican estas tecnologías han experimentado mejoras de productividad de 15-20% y de calidad de 10-15%. Estos beneficios quedaron patentes en los casos prácticos presentados por los expositores en CHINAPLAS.

Control de calidad basado en datos

El control de calidad en la fabricación se ha basado tradicionalmente en muestreos periódicos y pruebas fuera de línea. CHINAPLAS 2025 presentó sistemas avanzados de control en línea que evalúan continuamente la calidad del producto en tiempo real, lo que permite tomar medidas correctivas inmediatas cuando se producen desviaciones.

Estos sistemas emplean diversas tecnologías, entre ellas

- Medición láser para precisión dimensional

- Análisis por infrarrojos para verificar la composición de los materiales

- Sistemas de visión para la detección de defectos superficiales

- Pruebas ultrasónicas para evaluar la estructura interna

Al integrar estos sistemas de control de calidad con los sistemas de control de procesos, los fabricantes pueden implantar un control de bucle cerrado que ajusta automáticamente los parámetros del proceso para mantener una calidad óptima. Este enfoque no solo mejora la consistencia del producto, sino que también reduce el desperdicio de material y el consumo de energía.

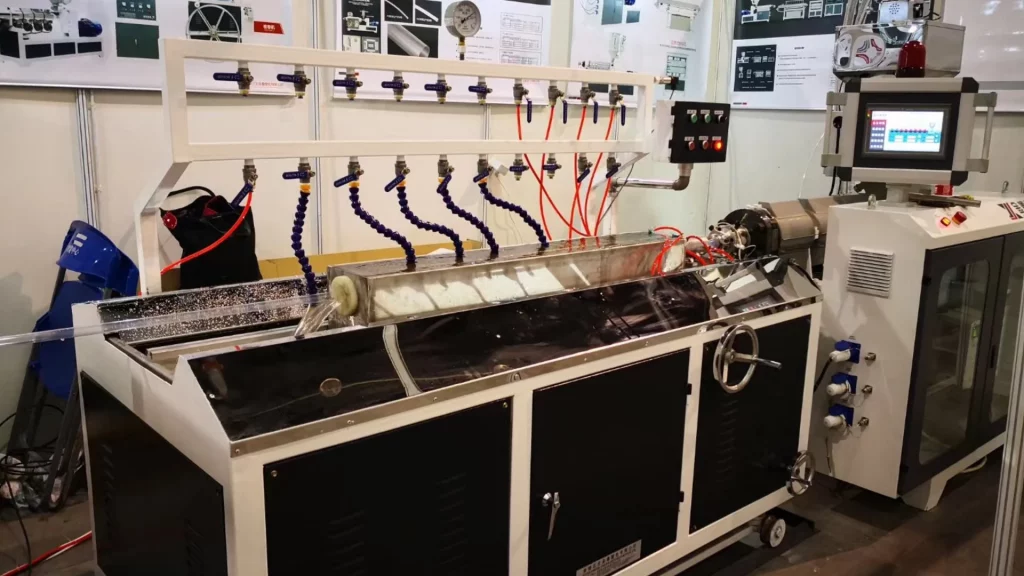

¿Cómo se comportaron los equipos de Jinxin en Chinaplas 2025?

¿Busca soluciones de extrusión fiables? El escaparate de Jinxin en Chinaplas 2025 destacó nuestro enfoque en la fiabilidad. Nuestro equipo de tubos de PC impresionó por su sólido rendimiento.

Se caracteriza por una extrusión precisa y un corte eficaz, lo que reduce los residuos al tiempo que garantiza la calidad para aplicaciones como la iluminación LED y la construcción.

China fabricante de extrusoras con nuestro cliente en CHINAPLAS 2019

China fabricante de extrusoras con nuestro cliente en CHINAPLAS 2019

china single screw extruder machine factory website PC banner

china single screw extruder machine factory website PC banner

Maquinaria Jinxin en Chinaplas 2025

Maquinaria Jinxin en Chinaplas 2025

Por qué los visitantes se fijaron en nuestros equipos

En Jinxin, nuestro objetivo es resolver los retos reales de fabricación. Nuestra extrusora de tubos de PC en Chinaplas 2025 lo demostró a través de su precisión y eficiencia. Los visitantes apreciaron sus ventajas prácticas, como la reducción del desperdicio de material y el uso de energía, que se ajustan a las demandas de la industria.

| Característica | Beneficio |

|---|

| Extrusión de precisión | Calidad homogénea en toda la producción |

| Corte eficaz | Menos residuos, operaciones más rápidas |

| Eficiencia energética | Costes más bajos, funcionamiento sostenible |

| Versatilidad | Funciona para LED, construcción y más |

¿Cómo pueden los fabricantes aplicar los conocimientos de CHINAPLAS 2025 a su negocio?

Después de asistir a ferias del sector, muchos fabricantes tienen dificultades para aplicar eficazmente los conocimientos adquiridos. La sobrecarga de información, las prioridades contrapuestas y la escasez de recursos impiden a menudo a las empresas sacar provecho de las valiosas conclusiones de las ferias. Un enfoque estratégico es esencial para traducir los conocimientos adquiridos en resultados empresariales tangibles.

Para los fabricantes de las industrias del plástico y el caucho, CHINAPLAS 2025 proporcionó una gran cantidad de información sobre las tendencias del mercado, las innovaciones tecnológicas y las necesidades de los clientes. Convertir estos conocimientos en estrategias prácticas requiere un enfoque sistemático centrado en la innovación, la sostenibilidad y el compromiso de los clientes.

Desarrollo de la hoja de ruta de la innovación

Uno de los resultados más valiosos de CHINAPLAS 2025 es la oportunidad de desarrollar una hoja de ruta estratégica basada en las tendencias observadas en el sector y en la evaluación comparativa de la competencia. Esta hoja de ruta debería alinear los esfuerzos de desarrollo de productos con las necesidades emergentes del mercado y las posibilidades tecnológicas.

En Jinxin, utilizamos los conocimientos adquiridos en CHINAPLAS para informar a nuestros clientes. estrategia empresarialcentrándose en áreas clave como:

- Garantizar que nuestros equipos puedan procesar eficazmente materiales sostenibles

- Exploración de sistemas de control digital para mejorar la eficacia de los procesos

- Desarrollar soluciones acordes con las tendencias del mercado

- Mejorar la eficiencia energética de nuestros diseños para reducir los costes de explotación

Analizando sistemáticamente los resultados de las exposiciones e integrándolos en una hoja de ruta estructurada, los fabricantes pueden garantizar que sus esfuerzos de desarrollo responden a auténticas necesidades del mercado, en lugar de perseguir la tecnología porque sí.

Estrategias de captación de clientes

Más allá del desarrollo de productos, CHINAPLAS 2025 aportó valiosas ideas sobre estrategias eficaces de captación de clientes. La exposición mostró diversos enfoques para demostrar el valor, comunicar las capacidades técnicas y establecer relaciones a largo plazo.

Las lecciones clave para los fabricantes incluyen:

| Estrategia | Aplicación | Beneficios |

|---|

| Marketing orientado a las soluciones | Centrarse en los problemas del cliente más que en las especificaciones técnicas | Mensajes más resonantes, conexiones más fuertes con los clientes |

| Demostraciones de aplicaciones específicas | Mostrar equipos de procesamiento de materiales pertinentes para las industrias destinatarias | Propuesta de valor más clara, prueba de capacidad más convincente |

| Análisis del coste total de propiedad | Destacar los beneficios económicos a largo plazo más allá del precio de compra inicial | Mayor justificación de los equipos de calidad |

| Mensajes de sostenibilidad | Destacar las ventajas medioambientales de los equipos | Alineación con los objetivos de sostenibilidad del cliente |

| Herramientas de compromiso digital | Demostraciones virtuales, herramientas de configuración en línea | Alcance ampliado más allá de las exposiciones físicas |

Aplicando estas estrategias de captación de clientes, los fabricantes pueden convertir más eficazmente los contactos de las ferias en relaciones comerciales duraderas.

Conclusiones: El futuro de la fabricación de plásticos y caucho

CHINAPLAS 2025 reveló un claro camino a seguir para las industrias del plástico y el caucho, definido por la sostenibilidad, la digitalización y la innovación de materiales. Para los fabricantes que quieran seguir siendo competitivos, adaptarse a estas tendencias no es opcional, sino esencial para el éxito futuro.

En Jinxin Plastic Machinery, estamos comprometidos a incorporar estos conocimientos en nuestro enfoque de diseño de equipos y servicio al cliente. Le invitamos a explore nuestras soluciones de extrusión especializadas o contacte con nuestro equipo para hablar de cómo podemos ayudarle a navegar por el cambiante panorama de la tecnología de fabricación de plásticos.