Trying to understand what is plastic extruder machine can feel complex, especially when considering manufacturing upgrades or new product lines. This lack of clarity about the nature of a plastic extruder machine can lead to inefficient production, poor investments, and quality issues, hindering your business growth. This guide clearly explains what is plastic extruder machine: its definition, how this type of extrusion equipment works, its components, types, and applications.

Fundamentally, what is a plastic extruder machine? It’s a device transforming raw plastic materials (like pellets, granules, or powder) into a continuous profile or shape. It achieves this by melting the plastic and then forcing it through a specifically shaped die. This process, known as plastic extrusion, is fundamental for creating a vast array of plastic products.

Understanding What is a Plastic Extruder Machine and How It Can Revolutionize Your Production? 1

Understanding What is a Plastic Extruder Machine and How It Can Revolutionize Your Production? 1

Now that we’ve scratched the surface, you’re probably wondering how this technology can specifically benefit your operations. I remember when I first started in this industry over a decade ago; understanding the intricacies of each machine, especially the plastic extruder machine, felt like learning a new language. But once I grasped the fundamentals, it opened up a world of possibilities. Let’s dive deeper into the workings and benefits of this essential equipment.

The Core Process: How Does a Plastic Extruder Machine Work?

Feeling that simple explanations of this extrusion equipment leave out critical operational details? A detailed look at the plastic extrusion process reveals the sophisticated engineering within a plastic extruder machine.

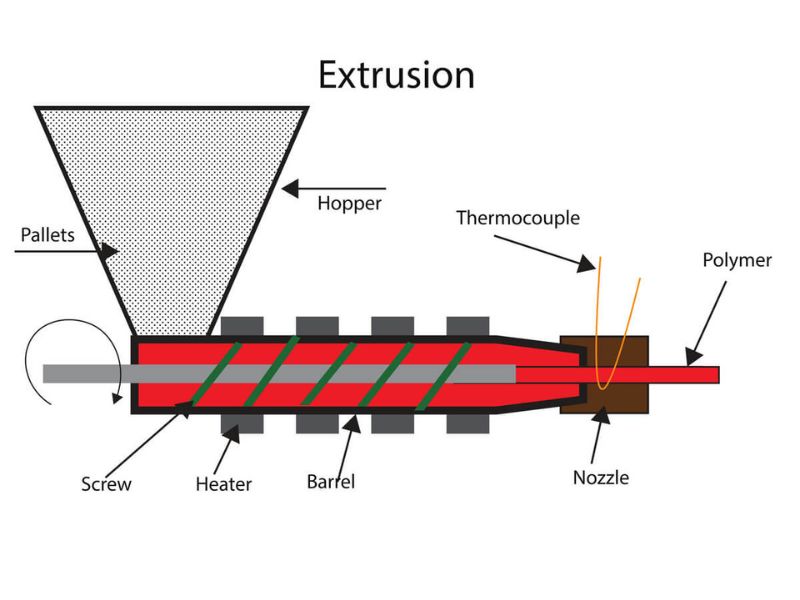

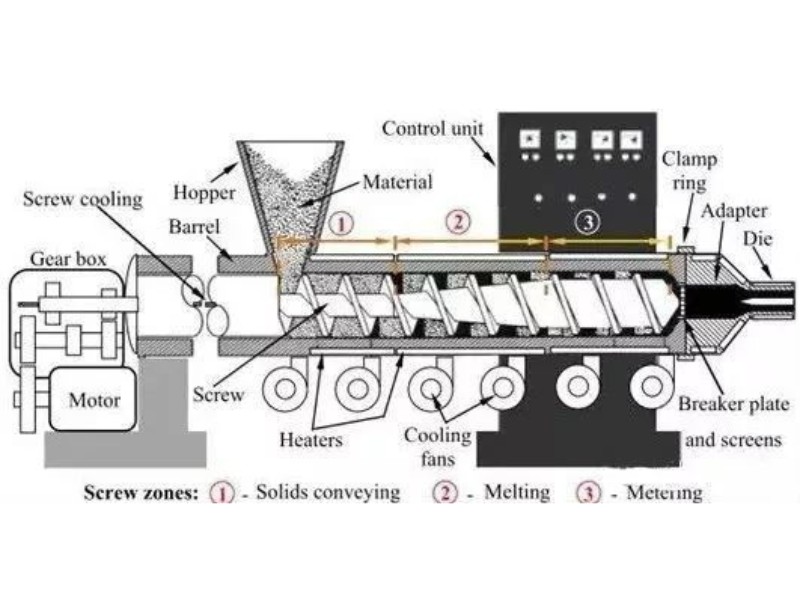

Essentially, a plastic extruder machine meticulously controls the transformation of solid plastic raw material into a precisely shaped molten stream. This is achieved through a synergistic combination of conveying, heating, mixing, pressurizing, and shaping within its core components.

Detailed cutaway diagram of a plastic extruder machine screw and barrel, illustrating the working principle

Detailed cutaway diagram of a plastic extruder machine screw and barrel, illustrating the working principle

The Extrusion Symphony: A Deeper Dive into the Actions Defining What is Plastic Extruder Machine

To fully appreciate the function of a plastic extruder machine, we must look beyond a simple definition. We explore the intricate dance of mechanics and thermodynamics occurring within it. The plastic extrusion process is far more than just “melt and push.” It’s a carefully orchestrated sequence that defines the achievable product quality and consistency from this type of extrusion equipment. I’ve spent years perfecting Jinxin’s machines, focusing on optimizing each of these internal steps.

Understanding What is a Plastic Extruder Machine and How It Can Revolutionize Your Production? 2

Understanding What is a Plastic Extruder Machine and How It Can Revolutionize Your Production? 2

1. Precision Material Input (The Hopper and Feed Throat):

The journey begins at the hopper. Consistent and accurate feeding of the raw plastic (pellets, granules, or powder) into the plastic extruder machine is foundational.

The design of the feed throat, sometimes cooled, ensures that material flows steadily into the screw channels without premature melting or bridging. This can disrupt the entire process. For some materials, especially those sensitive to moisture like PET or Nylon, the hopper system might integrate a dryer, because the material quality is critical for the plastic extruder machine’s performance.

2. The Screw – The True Heart of the Plastic Extruder Machine:

The extruder screw is not just a simple conveyor; its complex geometry is meticulously designed. Understanding the distinct zones of a screw is critical to understanding how the plastic extruder machine processes the polymer:

* Feed Zone (Solids Conveying): This initial section has deep flights. It is primarily responsible for transporting the solid plastic particles from the feed throat and compacting them. The efficiency here dictates the throughput of the extrusion equipment.

* Transition Zone (Melting/Plasticizing Zone): This is where the core transformation happens. The screw channel depth gradually decreases, compressing the material. Most of the melting occurs here due to conductive heat transfer from the heated barrel walls and shear heat generation from the rotating screw. This balance is vital within the plastic extruder machine.

* Metering Zone (Melt Pumping Zone): With shallow flight depths, this zone ensures the molten plastic is homogenized to a uniform temperature and pressure before it reaches the die. It acts like a positive displacement pump, providing a consistent, surge-free flow of melt. This consistency is paramount for the quality produced by the plastic extruder machine.

3. The Barrel – More Than Just a Container:

The barrel works in tandem with the screw in the plastic extruder machine. It’s not just a passive housing. Its robust construction withstands immense pressure. Its multiple, independently controlled heating zones allow for a precise temperature gradient. This is crucial for different stages of melting and for different polymers. Some advanced plastic extruder machine barrels might have special wear-resistant liners or venting ports for devolatilization.

4. Pressure Development and Die Shaping:

As the molten plastic is pumped by the metering section of the screw, it encounters resistance at the die. This builds up significant pressure. This pressure is essential to force the viscous melt through the precisely shaped die orifice of the plastic extruder machine. The die’s design—its land length, approach angles, and material of construction—are all critical factors in the shape complexity, surface finish, and dimensional accuracy the extrusion equipment can produce. For example, a die for a pipe extruder is vastly different from one for thin film.

5. Controlled Cooling and Downstream Handling:

The function of the plastic extruder machine doesn’t end at the die exit. The journey continues with controlled cooling (water baths, air knives, chill rolls) to solidify the extrudate while maintaining its shape. This is followed by downstream equipment like pullers, cutters, or winders. The entire extrusion line, centered around the plastic extruder machine, works as an integrated system.

This detailed understanding of the internal workings, often detailed in reputable industry publications and academic resources on polymer processing, truly clarifies the sophisticated nature of a plastic extruder machine.

| Internal Process Stage of a Plastic Extruder Machine | Key Action of the Extrusion Equipment | Critical Factors |

| Hopper & Feed Throat | Ensures consistent, conditioned raw material input | Material form (pellet/powder), drying, feed consistency |

| Screw – Feed Zone | Solids conveying and initial compaction | Screw design, L/D ratio, material characteristics |

| Screw – Transition Zone | Primary melting via shear and conductive heat | Compression ratio, barrel temperature, screw speed |

| Screw – Metering Zone | Melt homogenization and pressurized pumping | Channel depth, melt viscosity, pressure stability |

| Barrel Function | Provides controlled thermal environment and pressure containment | Temperature profile accuracy, wear resistance |

| Die Extrusion | Shapes the molten plastic under pressure | Die design, land length, material swell |

| Cooling & Downstream | Solidifies product and prepares for final use | Cooling rate, haul-off speed, cutting precision |

This intricate process underscores that a plastic extruder machine is a precision instrument for polymer transformation.

Exploring Variations: What are the Different Types of Plastic Extruders?

While single-screw and twin-screw plastic extruder machines cover most applications, a comprehensive understanding acknowledges other designs. These cater to unique materials or specific needs. Beyond common single and twin-screw configurations, specialized types of plastic extruders include Ram Extruders and Multi-Screw Extruders. Co-extrusion setups also utilize multiple plastic extruder machines for layered products.

| Type of Extrusion Equipment | Key Defining Feature(s) | Primary Application Area(s) | Typical Materials |

| Single-Screw Plastic Extruder Machine | One rotating screw | General purpose pipes, profiles, films, sheets | Most thermoplastics (PE, PP, PVC, PS) |

| Twin-Screw Plastic Extruder Machine | Two intermeshing screws (co- or counter-rotating) | Compounding, mixing, reactive extrusion, difficult materials | PVC powder, filled plastics, blends |

| Ram Plastic Extruder Machine | Plunger pushes material billet | Materials difficult for screw extrusion | PTFE, UHMWPE |

| Multi-Screw Plastic Extruder Machine | More than two screws for intensive mixing | Specialized compounding, heat-sensitive materials | PVC, high-filler content |

| Co-Extrusion System (multiple units) | Multiple extruders feeding one multi-manifold die | Multi-layer films, pipes, profiles with distinct layers | Various, depending on layer needs |

This broader view of types of plastic extruders helps in appreciating the full scope and potential of plastic extruder machine technology.

Single-Screw vs. Twin-Screw Plastic Extruder Machine: A Detailed Comparison for Informed Choices

When I advise clients at Jinxin, one of the first questions we address is regarding the main types of plastic extruders: specifically, whether a single-screw plastic extruder machine or a twin-screw plastic extruder machine is more suitable. This isn’t just a technical detail; it fundamentally affects the plastic extrusion process and the range of products you can efficiently manufacture. Both types of plastic extruder machine have their merits, and the “best” choice truly depends on your materials, desired output, and application complexity.

Single-Screw Plastic Extruder Machines:

This is the most common and, in many ways, the workhorse of the extrusion industry. As the name suggests, a single-screw plastic extruder machine utilizes one rotating screw housed within the barrel. Its primary functions are to convey, melt, and pressurize the plastic material.

- Advantages:

- Cost-Effectiveness: Generally, single-screw plastic extruder machines have a lower initial investment cost and are often simpler to maintain due to fewer moving parts in the core processing unit.

- Simplicity of Operation: Their design is relatively straightforward, making them easier to operate and understand, especially for factories new to extrusion or those producing standard products.

- Good for Many Standard Thermoplastics: They perform very well with a wide range of common thermoplastics like Polyethylene (PE), Polypropylene (PP), Polystyrene (PS), and rigid/flexible PVC, especially when intensive mixing or compounding isn’t required. This makes them ideal for applications like our Jinxin small diameter PP/PE Pipe Extrusion Equipment or dip tube lines.

- Efficient Pumping: Single-screw designs are inherently good at building up pressure for die extrusion.

- Limitations:

- Limited Mixing Capability: Compared to twin-screw designs, their ability to mix different materials or incorporate high levels of additives/fillers is less efficient.

- Shear Control: Managing shear rates and ensuring uniform melt temperature for very heat-sensitive materials can be more challenging.

Twin-Screw Plastic Extruder Machines:

A twin-screw plastic extruder machine features two intermeshing screws, which can be co-rotating (spinning in the same direction) or counter-rotating (spinning in opposite directions). This dual-screw design significantly enhances mixing, compounding, and heat transfer capabilities.

- Advantages:

- Superior Mixing and Compounding: This is the standout benefit. The intermeshing screws provide excellent distributive and dispersive mixing, making them ideal for creating alloys, compounding additives/fillers, and masterbatch production.

- Better Process Control: Twin-screw plastic extruder machines offer more precise control over shear rates and residence time distribution, which is beneficial for heat-sensitive materials (like some PVC formulations or bioplastics) and reactive extrusion.

- Versatility with Materials: They can handle a wider range of materials, including those that are difficult to process in a single-screw plastic extruder machine, such as powders, heat-sensitive polymers, and materials requiring devolatilization (removal of volatiles like moisture or monomers).

- Self-Wiping Action: Co-rotating twin screws often have a self-wiping characteristic, which helps prevent material stagnation and degradation.

- Limitations:

- Higher Cost: Twin-screw plastic extruder machines are generally more expensive to purchase and can have higher maintenance costs due to the complexity of the screws and gearbox.

- More Complex Operation: They typically require more skilled operators due to the increased number of process variables.

- Lower Pumping Efficiency (Sometimes): While excellent for mixing, their pressure-building capability per unit length might be lower than single-screw extruders for certain designs, though this is highly design-dependent.

I often speak with clients interested in PVC pipe or profile production using a plastic extruder machine. They’ll send an inquiry, sometimes assuming a single-screw plastic extruder machine is suitable. My first crucial question is always: “Are you using PVC powder or PVC granules?”

If the answer is powder, I explain that a twin-screw plastic extruder machine is generally necessary for its superior mixing and heat transfer. These are vital for processing powder directly into a quality product. A single-screw plastic extruder machine, in this case, would likely struggle. This simple question about raw material form immediately highlights a key difference in application between these two types of plastic extruders. It helps ensure the client invests in the right plastic extruder machine technology from the start.

Understanding these types of plastic extruders is the basis for choosing a plastic extruder. We have a more detailed comparison of the two types of extruders for you to read.

Understanding these variations, as detailed in accessible resources like Wikipedia’s entry on Plastic Extrusion, provides a fuller picture. Knowing these forms exist underscores the adaptability of plastic extruder machine technology.

Common Applications: What Can Plastic Extruders Create?

Plastic extruders are incredibly versatile, used to manufacture a vast array of products across numerous industries:

- Pipes and Tubing: From large-diameter water and gas pipes to small, precise medical tubing and automotive fuel lines. Jinxin Angle: Jinxin manufactures lines for small diameter PP/PE water pipes, precision dip tubes for pumps and spray bottles, and flexible PVC braided reinforced hoses.

- Profiles: Custom shapes like window frames, door seals, decorative trim, LED lighting diffusers, and wire conduits. Jinxin Angle: Our equipment produces PC/PMMA LED lighting profiles and various PVC co-extruded profiles.

- Sheets and Films: Used for packaging, signage, construction (e.g., vapor barriers), and thermoforming applications.

- Specialty Products: This includes items like TPE elastic bands for medical or fitness use. Jinxin Angle: Jinxin produces extrusion lines for TPE elastic bands suitable for tourniquets, Esmark bands, and resistance bands.

Understanding Raw Materials for Extrusion

A wide variety of thermoplastic materials can be processed through extrusion, including:

- Polypropylene (PP): Versatile, good chemical resistance, used for pipes, containers.

- Polyethylene (PE – including LDPE, HDPE): Widely used for films, bags, bottles, pipes.

- Polyvinyl Chloride (PVC): Can be rigid or flexible, used for pipes, window frames, hoses.

- Polycarbonate (PC): Strong, impact-resistant, transparent, used for LED profiles, safety glasses.

- Polymethyl Methacrylate (PMMA/Acrylic): High clarity, weather resistant, used for lighting fixtures, signs.

- Thermoplastic Elastomers (TPE): Rubber-like properties, used for seals, soft-touch grips, elastic bands.

Jinxin Angle: We use our professional equipment knowledge and years of customer feedback to help you to select the most suitable raw materials, such as to tell you what kind of hardness of raw materials is most suitable for what type of products, and TPE raw materials authorized sales.

Key Considerations: How to Choose the Right Plastic Extruder Machine?

Feeling unsure about what is plastic extruder machine specification truly means for your business? Making an informed decision when choosing a plastic extruder requires a clear understanding of your needs matched against machine capabilities.

Choosing a plastic extruder machine is a significant investment, and understanding what is plastic extruder machine should offer for your specific circumstances is paramount. It’s not just about buying a piece of equipment; it’s about acquiring a solution that aligns with your production goals, materials, and business strategy. Over the years at Jinxin, I’ve guided countless clients through this process, helping them translate their needs into machine specifications.

- For Experienced Buyers (Upgrading): Focus on machines that offer improved efficiency, higher output rates, enhanced reliability for consistent quality, better material compatibility for new formulations, and seamless integration with existing downstream equipment. Jinxin Angle: Jinxin provides cost-effective upgrade paths with modern, reliable extruders designed for enhanced performance and ease of maintenance.

- For New Buyers (New Product Lines): Prioritize understanding basic configurations, ease of operation, the required output for your target market, versatility for potential future products, and comprehensive training and support from the supplier. Jinxin Angle: For newcomers, Jinxin offers guidance from initial consultation through equipment selection and process setup, ensuring you get a solution tailored to your needs without being oversold.

- For Middlemen (Equipment Resellers): Look for manufacturers with a strong reputation for machine quality and reliability, a good range of applications covered, readily available technical specifications and spare parts, and responsive support for your clients. Jinxin Angle: Jinxin builds long-term relationships by offering dependable, high-quality machines that are well-supported, making us a trusted partner for equipment resellers.

| Buyer Consideration for Plastic Extruder Machine | Key Question to Define Needs | Jinxin’s Approach |

| Material Type & Form | What specific polymer(s) and form will be processed? | Expert advice on screw design and machine type. |

| Output Rate Required | What is the target production volume ( kg/hr )? | Matching machine size to current and future output needs. |

| Product Specifications | What are the dimensions, tolerances, and complexity of the product? | Tailoring die design and downstream equipment for precise outcomes. |

| Budget & Total Cost of Ownership | What is the initial budget and long-term operational costs? | Providing cost-effective, reliable solutions with excellent long-term value. |

| Automation & Control Needs | What level of process control and automation is desired? | Offering a range of control systems from user-friendly basic to advanced PLC. |

| Supplier Support & Training | What level of after-sales service and training is expected? | Comprehensive support, readily available spare parts, and thorough training programs. |

By carefully evaluating these factors, you can clearly define the plastic extruder machine that will best serve your business.

Maintenance and Operation of Plastic Extruder Machines

Routine maintenance is essential for long-term reliability:

- Regular inspection and cleaning of screw, barrel, and die

- Monitoring of temperature and pressure sensors

- Lubrication and alignment of mechanical parts

- Scheduled replacement of wear components

Jinxin provides comprehensive maintenance manuals and technical support. For best practices, refer to our Extruder Maintenance Checklist, which offers a detailed maintenance program covering control panels, feedscrews, barrels, and other critical components

Future Trends in Plastic Extruder Machines

The future of plastic extruder machines is exciting. We’re seeing trends like:

- Automation: Smart controls for precision.

- Sustainability: Machines designed for recycled plastics.

- Energy Efficiency: Lower costs and environmental impact.

At Jinxin, we’re leading the way in innovating plastic extruder machine technology.

Conclusion

Our comprehensive exploration to understand what is plastic extruder machine reveals its sophisticated and pivotal role. From the detailed mechanics of the plastic extrusion process, the diverse types of plastic extruders, to the critical plastic extruder components and crucial factors in choosing a plastic extruder, it’s clear this is more than a simple machine. This knowledge helps clarify the full scope of this extrusion equipment.

At Jinxin, we provide solutions built on experience, helping you understand the best plastic extruder machine for your specific success. This includes guidance on plastic extruder maintenance (see our dedicated guide) and deciphering plastic extruder machine price considerations. Further general information on plastics processing can often be found through organizations such as the Plastics Industry Association or the British Plastics Federation (BPF).