The PPR Pipe Extrusion Machine, Perfected by Experience

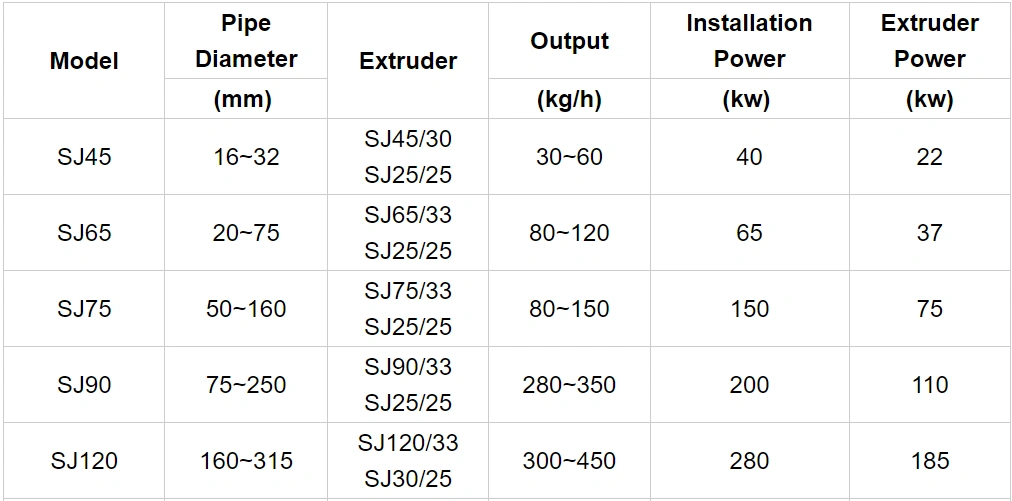

Detailed Parameters of PPR Pipe Extrusion Machine Line

The item “Extruder” in the figure below contains an auxiliary extruder for extruding the marking lines.

Our Story is Your Advantage: Perfecting the PPR Pipe Extrusion Machine

Over a decade ago, when PPR pipes first revolutionized plumbing, we were there. We didn’t just build equipment; we engineered the first generation of the modern PPR pipe extrusion machine. We supplied them to pioneers, including one of our own former partners who built a successful pipe export factory with our technology. We witnessed the industry’s growth and its challenges.

Today, as rising shipping costs make local production a smarter choice, we offer you not just a machine, but a complete PPR pipe production line born from that unique history. We know what it takes for a PP-R pipe making machine to succeed, because we’ve been part of the story.

Your Machine, Configured for Your Market

Let’s be honest: the basic design of these machines is now a solved puzzle. The true difference isn’t in the blueprint, but in the build quality—the things you don’t see on a spec sheet. Is the frame built with solid, heavy-gauge steel? Is the electrical work clean and safe? Crucially, a higher price tag doesn’t guarantee better answers to these questions.

Our focus is simple: invest in the robust build of the machine, not in a brand name. This is the real foundation of long-term reliability.

Tell us your goal.

Need to produce standard single-layer pipes at high speed? We will optimize the line for maximum output.

Need to enter the market for 3-layer glass-fiber reinforced (PPR-GF-PPR) pipes? We will seamlessly integrate the co-extrusion system for you.

Our 20 years of experience means we know how to reliably configure the right PPR pipe extrusion machine line for any requirement. We ensure every configuration, simple or complex, is engineered to be stable and easy to operate.

Let’s discuss the right setup for your business goals. Contact Us for a Free Consultation.

REQUEST A quote

Want to Know More? Discover Our Full Production Line Below

PPR PIPE EXTRUSION MACHINE

Understanding PPR Pipe Extrusion: Process & Critical Components

In manufacturing, downtime is the enemy of profit. Our PPR pipe extrusion machine is therefore built on a single, guiding principle: reliability over complexity. This is achieved through the two key pillars below.

Robust Core Components

Beyond the Blueprint

Technical Excellence: Key Features of PPR Pipe Extrusion Machine Line

Main Extruder

The main extruder machine is the core component where PP-R pellets are melted and homogenized. It consists of a barrel, screw, and heaters. The rotating screw, driven by a powerful motor, pushes the pellets through the barrel, where they are gradually melted by the heat.

Temperature Control: Equipped with state-of-the-art PLC control systems and touch screen interfaces, our machines ensure precise control over the extrusion process, guaranteeing superior quality in every production run.

Vacuum Sizing Tank

The vacuum sizing tank stabilizes the shape of the molten PPR pipe by using a vacuum to pull it against the sizing sleeve. This process ensures that the pipe retains its correct dimensions as it cools and solidifies.

Details:

- Cooling System: Equipped with an efficient cooling system to rapidly solidify the pipe.

- Adjustable Spray Angle: Allows for precise control of the cooling process, enhancing dimensional stability

Cooling Tank

The cooling tank further cools the pipe to ensure its structural integrity and dimensional accuracy. It usually follows the vacuum sizing tank in the production line.

Details:

- Length: Typically designed in segments to provide adequate cooling.

- Cooling Method: Uses water sprays or baths to evenly cool the pipe, preventing warping and ensuring uniform thickness

Haul-Off Unit

The haul-off unit pulls the pipe through the extrusion line at a consistent speed, which is crucial for maintaining uniform diameter and wall thickness.

Details:

- Caterpillar Tracks: Multiple tracks driven by independent motors ensure smooth and even pulling.

- Speed Control: Precisely adjustable to match the extrusion speed and ensure product consistency

Cutter

The cutter precisely cuts the extruded pipes to the required lengths. This unit is designed to make clean, accurate cuts without damaging the pipes.

Details:

- Type: Non-dust or planetary cutters are commonly used for their precision and efficiency.

- Operation: Often equipped with servo motors for enhanced control and adaptability to different pipe sizes

PPR PIPE EXTRUSION MACHINE LINE Q&A

May help you know more

What are the main components of a PPR pipe extrusion machine?

A complete PPR pipe extrusion machine line typically consists of a high-efficiency single-screw extruder, a die-head for forming the pipe, a vacuum calibration tank for sizing and cooling, a haul-off machine for pulling, a planetary cutter for precise cuts, and a stacker for collection.

Each component is synchronized by a central control system to ensure a smooth and stable PPR pipe manufacturing process.

What is the difference between single-layer and 3-layer PPR pipes?

A single-layer PPR pipe is made of 100% polypropylene random copolymer, suitable for standard plumbing.

A 3-layer pipe, often a PPR-GF-PPR pipe, has a middle layer of glass-fiber composite. This layer significantly reduces thermal expansion and increases pressure resistance, making it ideal for hot water applications.

Our PPR pipe making machine can be configured for both single and 3-layer production.

How does the cooling and calibration system ensure roundness and dimensional accuracy?

Let's be practical: if a critical part fails and my factory on the other side of the world stops, what is your actual emergency response plan?

This is the most important question. Our 3-step response is proven:

Immediate Remote Diagnosis: We connect via video call within hours to diagnose the issue. Most problems are solved this way.

Dual-Path for Parts: For replacements, you can either source the standard part (like ABB) locally for speed, or we ship it via DHL Express within 24-48 hours.

Prevention by Design: We use these reliable, globally-sourced components precisely to minimize the chance of this ever happening.`

About JINXIN Plastic Machinery

Since 2012

We are honest and reliable, providing cost-effective equipment for your factory

By choosing our equipment, you are partnering with a supplier dedicated to resolving your pain points with expertly curated, high-quality, and cost-effective solutions. We stand by the reliability and performance of every product we offer, ensuring that your investment delivers the results you need for your business to thrive.

Proven Quality

Over a decade of experience and customer feedback ensures our selected machines offer long-term durability and reliable performance.

Exceptional Value

We provide high-quality equipment at competitive prices, maximizing your investment with top-tier performance.

Reliable Support

Comprehensive support and service ensure smooth operation and minimal downtime, maintaining optimal productivity.

Our Customers Say

Our amazing Suppliers

EXTRUSION SOLUTIONS

Email Address

sales@jfextruder.com

Factory Address

No. 31 Yuci Rd., Yuyao, Ningbo City, Zhejiang Province, China