PVC fiber reinforced hose pipe extrusion line for washing machine inlet hose

PVC fiber reinforced hose pipe extrusion line for washing machine inlet hose

The customer uses our PVC braided reinforced pipe extrusion equipment to produce washing machine inlet pipe products, which are accessories for Samsung washing machines.

Producing high-quality washing machine inlet hoses is tough. Leaks or damage can ruin a washing machine. Jinxin’s extrusion line met Samsung’s strict standards, delivering reliability every time.

Our customer in Thailand is a parts manufacturing factory for Samsung washing machines. They produce pipe fittings such as water inlet pipes for all Samsung brand washing machines. This time we provided them with 3 sets of PVC braided reinforcement pipe extrusion equipment, and provided on-site installation and debugging services.

Below are the machine equipment configured in the PVC washing machine inlet hose production line in this project

- 2 main extruders, separately extruding and producing the inner and outer tube blanks

- 2 cooling sizing platforms

- 2 flat plate traction devices

- 1 braiding machine

- 1 finished product cutting and collecting platform

Why Did Samsung Choose Our Customer for Washing Machine Inlet Hoses Supplier?

Partnering with a giant like Samsung isn’t easy. Subpar hoses mean delays and costly fixes. Jinxin’s extrusion line delivered the quality and reliability they needed.

Samsung chose Jinxin for washing machine inlet hoses because our extrusion line offers unmatched precision, durability, and efficiency, proven by rigorous testing and consistent performance.

Precision That Wins Big Clients

Precision sets us apart. Our extrusion line for washing machine inlet hoses uses advanced co-extrusion to fuse PVC layers with braided reinforcement seamlessly. This ensures every hose is strong, flexible, and leak-proof—exactly what Samsung demanded.

We’ve fine-tuned our process over years. Mr. Jason’s early days in the industry taught us that details matter. Our equipment’s smart controls adjust on the fly, keeping production flawless. Samsung saw this precision in action and knew they could count on us. Curious about extrusion basics? See Fictiv’s guide.

Efficiency That Saves Time and Money

Time is money, especially for big manufacturers. Our extrusion line runs fast and smooth, cutting downtime and costs. For Samsung, this meant faster production without sacrificing quality. Every hose we made fit their timeline and budget, strengthening our partnership.

We don’t just build equipment—we solve problems. Our line’s design reduces waste and speeds up output. It’s practical, proven, and perfect for scaling up. Learn more about our extrusion solutions.

The specific details of the components of the washing machine inlet hose extrusion production line:

2 sets of extruders for producing inner and outer hoses SJ65/28 PLC system type extruders:

- ****Screw and Barrel: 65mm diameter screw barrel, L/D ratio 1:28. PVC special high-precision screw, nitriding treatment, hard chrome plating. The heating of the screw part adopts cast aluminum heating ring, with stainless steel wind hood, with cooling fan.

- ****Gearbox/ /Reducer: Hard tooth surface, Model: ZLYJ173. (Brand: JIYIDA)

- ****Motor & Inverter: 22KW 6 pole frequency conversion motor (Brand: Beide by SIEMENS) 22KW inverter (Brand: ABB 580 series high performance)

- ****Heating System: Solid-state relay controls heating.(Brand: FOTEK Taiwan)

- ****Control System: 10 inch touch screen, PLC system. With fault alarm function, with scheduled heating function, with synchronous speed regulation function

2 sets cooling sizing tanks for producing inner and outer hoses

- Length: 3 meters for inner hose

- Length: 4 meters for outer hose

- Equipped with a water pump

- Tanks Material: SUS 304 stainless steel

- Front and rear, left and right, height can be adjusted manually

2 sets flat type haul-off machines for producing inner and outer hoses

- Length: 1 meter

- Single motor with two reducers

- Gearbox coupling directly connected, with 2.2KW ABB frequency converter

- Electric adjustment of the upper traction up and down, manual adjustment of the lower traction up and down

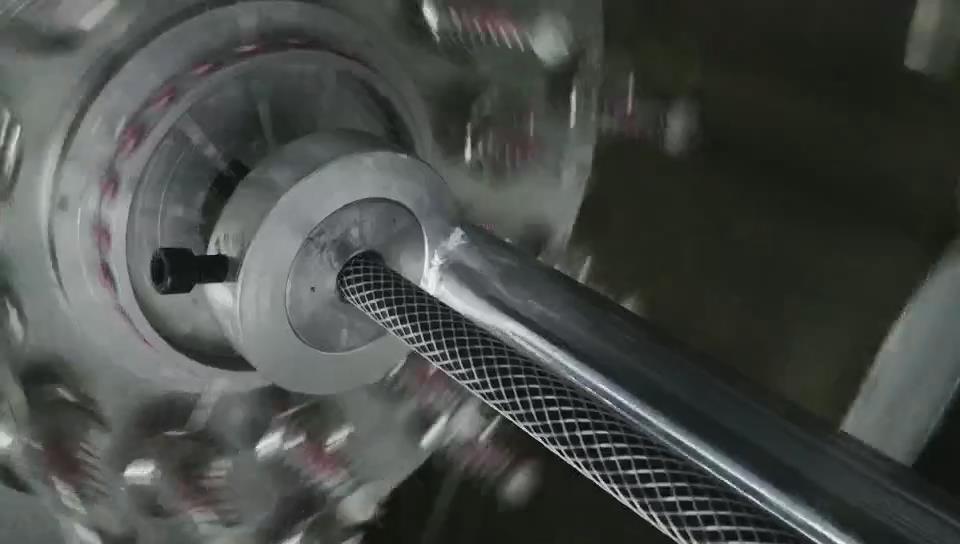

1 set braiding machine

- With 24 wire barrel

- Motor: Double motor, 1.5KW 6 pole frequency conversion motor

- Inverter: 5.5KW (Brand:ABB)

- The large disc is made of aluminum plate, the wire barrel is made of stainless steel, with a plastic cover

- With a tension regulator, and 4 stretch-reinforced wire barrels

1 set drying tunnel

- 6 heating tubes, with cooling fan, can be forced or automatic blowing, with temperature controller.

1 set finished washing machine inlet pipe cutting and collecting platform

- Pneumatic cutting, encoder to determine the cutting length

- With counting function.

- Collection of finished products, pneumatic flap to drop the collection box

braiding machine

braiding machine

PLC system extruder

PLC system extruder

water cooling tank without vacuum

water cooling tank without vacuum

Samsung washing machine inlet pipe sample made by our machine

Samsung washing machine inlet pipe sample made by our machine

braiding in process

braiding in process

Anatomy-of-a-braided-hose-pipe

Anatomy-of-a-braided-hose-pipe

In summary, due to the maturity of production equipment technology, the current cost of equipment is not high. If you use some small brands or locally produced electronic components to save the cost of buying equipment, it is easy to increase subsequent maintenance costs and reduce equipment usage time. All of our JINXIN equipment uses world-renowned brands like ABB, and the brand side will provide global warranty services. Including all our other parts, they are all suppliers screened out in the production process of more than 10 years, and the cost performance and quality are up to standard.

The washing machine inlet hose produced by our equipment has passed the test of the Samsung brand, which is enough to prove the quality of the products produced by our equipment. But our price advantage is obvious. The equipment price quoted by customers in Thailand is twice as high as ours. Welcome everyone to consult and choose our equipment.

Upgrading to reinforced hose production equipment helped this manufacturer achieve OEM success for washing machine inlet hoses. Want to transform your own production? Contact Jinxin today to discuss your needs!

Related Products:

reinforced hose extrusion line

reinforced hose extrusion line