Máquina de extrusão de tubo por imersão de alta precisão

pedir um orçamento

Calcular o ROI da máquina de extrusão de tubos Dip

Dominar a produção de tubos de imersão: Por dentro da nossa tecnologia de extrusão

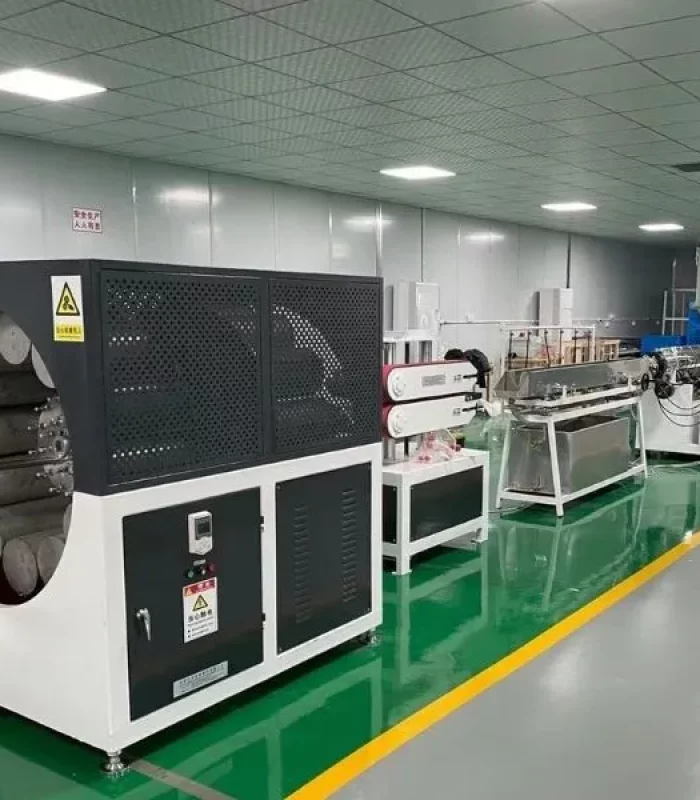

Para as empresas que necessitam de tubos de imersão de alta qualidade para embalagem, é fundamental conhecer o equipamento de fabrico correto. Esta secção analisa a forma como a nossa máquina de extrusão de tubos de imersão proporciona a precisão, a consistência e a eficiência de que necessita.

Concentramo-nos em benefícios diretos: maquinaria durável que produz tubos com especificações exactas, minimizando o desperdício e maximizando a sua produção de produtos prontos para o mercado. Explore os componentes que fazem da nossa solução um investimento inteligente.

Extrusora de parafuso único de precisão: Fornecimento consistente de massa fundida

O núcleo da linha de máquinas de extrusão de tubos por imersão, esta extrusora é especificamente optimizada para LDPE e PP.

Estes polímeros são escolhidos pelas suas excelentes propriedades na produção de tubos de imersão duráveis e precisos.

O design da nossa extrusora garante uma fusão uniforme e uma produção estável destes materiais, o que é fundamental para aplicações de paredes finas, e promove uma excelente plastificação para um fluxo de material consistente.

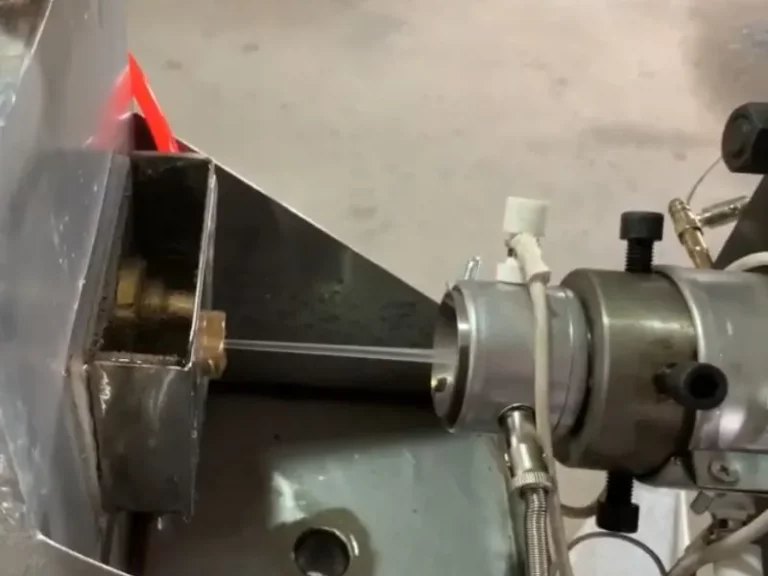

Cabeças de roscar e ferramentas especializadas: Formação de tubos sem defeitos

A nossa cabeça de matriz personalizada e as ferramentas de precisão são concebidas para os pequenos diâmetros e tolerâncias apertadas exigidas para os tubos de imersão.

Isto assegura dimensões exactas do tubo, superfícies lisas e espessura de parede consistente, vitais para a funcionalidade da bomba e do pulverizador.

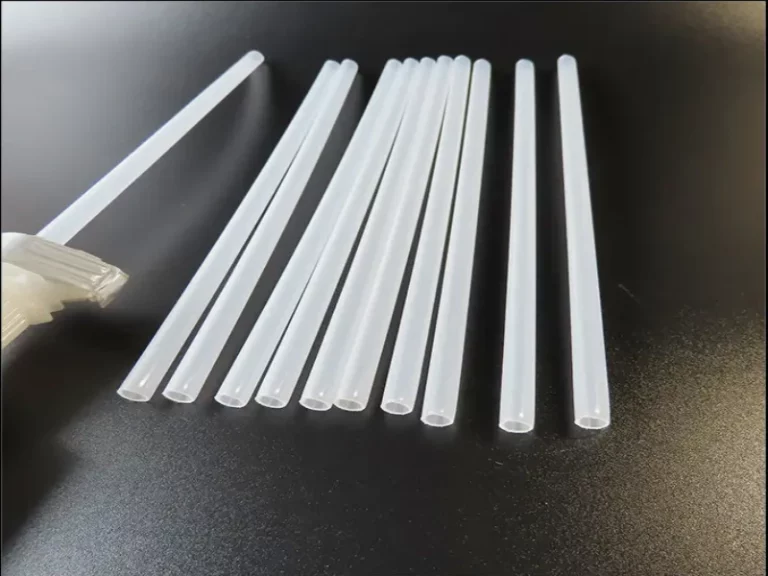

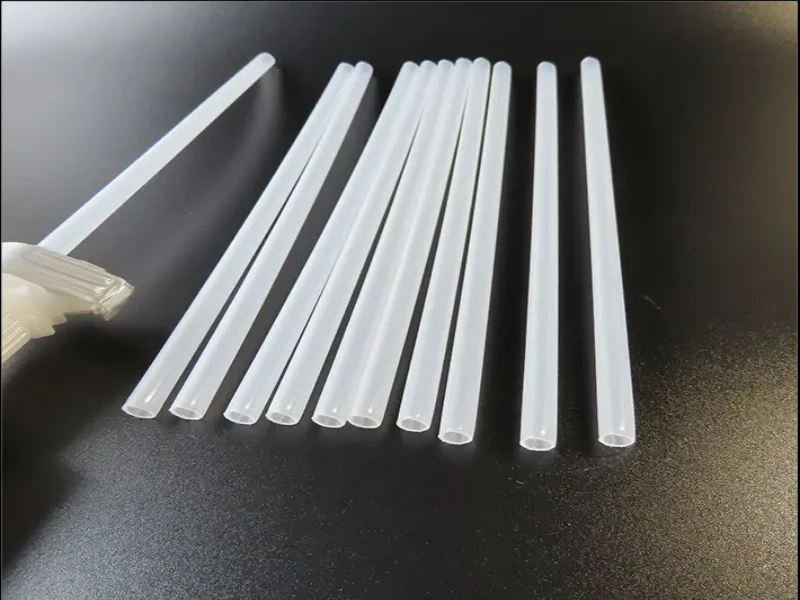

Dimensionamento a vácuo e tanque de arrefecimento: Solidificando a perfeição

Um sistema eficiente de dimensionamento a vácuo e de arrefecimento a água estabiliza rapidamente o tubo extrudido, assegurando que mantém a sua forma circular e diâmetro precisos.

Isto é crucial para produzir tubos de imersão rectos e de alta qualidade, prontos para a montagem.

Descolagem estável da correia: tração suave e precisa

A unidade de tração do tipo correia fornece uma força de tração suave e consistente, perfeitamente sincronizada com a extrusora.

Isto evita a distorção dos delicados tubos de imersão e mantém as dimensões uniformes ao longo da produção.

Cortador de precisão de alta velocidade: Cortes limpos, sempre

A nossa unidade de corte foi concebida para o corte preciso e a alta velocidade de tubos de pequeno diâmetro, proporcionando extremidades limpas e sem rebarbas.

Desta forma, os tubos de imersão estão prontos para serem utilizados imediatamente na montagem, sem qualquer outro processamento.

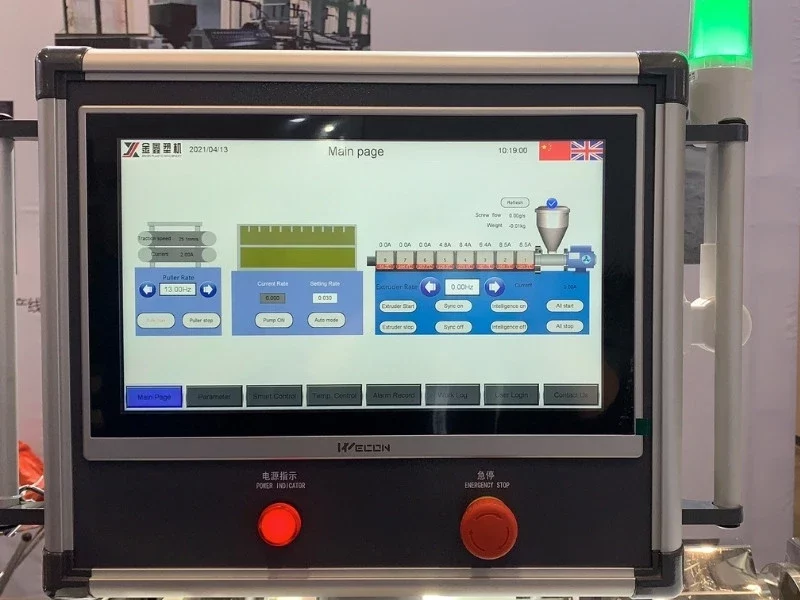

Sistema de controlo PLC de fácil utilização: Operação sem esforço

Toda a linha é gerida através de um sistema de controlo PLC intuitivo com uma interface de ecrã tátil e um sistema multilingue.

Permite uma fácil definição de parâmetros, monitorização do processo em tempo real e ajustes rápidos, simplificando o funcionamento e maximizando o tempo de atividade.

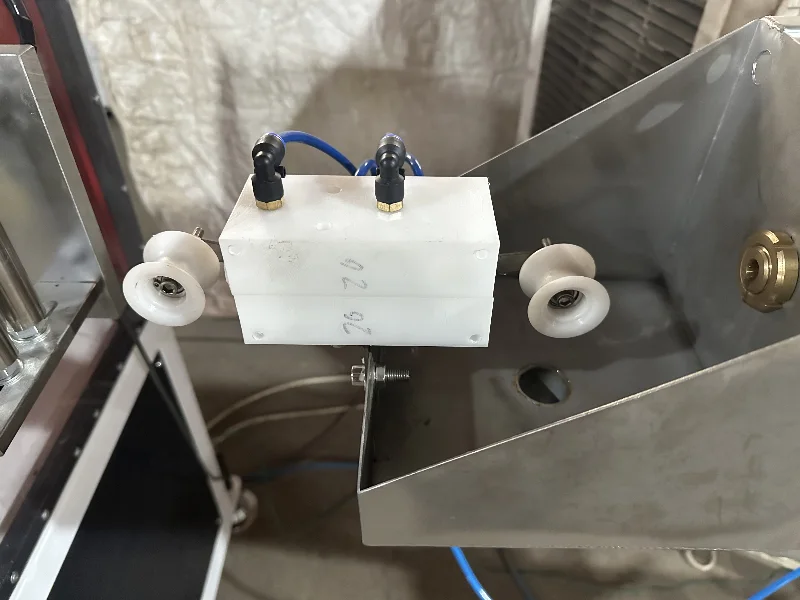

Precisão e cuidado em cada detalhe

A nossa máquina de extrusão de tubos de imersão reflecte um elevado nível de profissionalismo e uma conceção cuidada, nomeadamente com a adição de um pequeno dispositivo de sopro de ar na extremidade do reservatório de água. Posicionado imediatamente antes de os tubos entrarem na unidade de transporte, esta caraterística seca rapidamente qualquer água residual, assegurando que os tubos estão livres de humidade.

Isto serve dois objectivos fundamentais: melhora a forma final do tubo para uma qualidade superior e evita que a água pingue no chão da fábrica, reduzindo o risco de escorregadelas e mantendo um espaço de trabalho mais seguro e limpo. Este pequeno mas impactante pormenor sublinha o nosso compromisso com a precisão e a atenção às necessidades dos nossos clientes.

Qualidade comprovada

Mais de uma década de experiência e feedback dos clientes garantem que as nossas máquinas seleccionadas oferecem uma durabilidade a longo prazo e um desempenho fiável.

Valor excecional

Fornecemos equipamento de alta qualidade a preços competitivos, maximizando o seu investimento com um desempenho de topo.

Apoio fiável

A assistência e o serviço abrangentes garantem um funcionamento sem problemas e um tempo de inatividade mínimo, mantendo uma produtividade óptima.

O que dizem os nossos clientes

Os nossos fantásticos fornecedores

Respostas às suas perguntas: Máquina de extrusão de tubos de imersão

Pode ajudá-lo a saber mais

Qual é a gama típica de diâmetros e tolerâncias que a sua máquina de extrusão de tubos de imersão pode atingir? Isto é fundamental para a montagem da nossa bomba.

A nossa máquina foi especificamente concebida para tubos de pequeno diâmetro, normalmente entre 1,5 mm e 8 mm de diâmetro externo (DE), com um excelente controlo de tolerância, muitas vezes dentro de +/- 0,1 mm, dependendo do material e do tamanho do tubo.

Compreendemos que um ajuste preciso é crucial e o nosso sistema foi concebido para proporcionar essa consistência para uma integração perfeita com os seus mecanismos de bomba e pulverizador.

Precisamos de produzir tubos de imersão em LDPE e PP. É fácil mudar de material na vossa máquina e isso afecta o desempenho?

A mudança entre LDPE e PP é simples. Embora seja necessária alguma purga, o nosso design de cabeça de rosca e matriz facilita uma mudança de material eficiente. Fornecemos diretrizes claras para este processo.

O desempenho permanece ótimo para ambos os materiais, uma vez que os perfis de aquecimento da máquina e a geometria do parafuso foram concebidos para lidar eficazmente com as suas caraterísticas específicas de processamento.

Como é que a vossa máquina garante a retidão dos tubos de imersão? Os tubos dobrados causam problemas nas nossas linhas de montagem.

A retidão do tubo é um aspeto fundamental. O nosso sistema garante-o através de uma combinação de factores: conceção optimizada da matriz para um fluxo de material uniforme, dimensionamento a vácuo preciso e estável que forma e suporta corretamente o tubo durante o arrefecimento, e um sistema de corte e transporte devidamente alinhado.

Isto minimiza as tensões internas que podem levar à flexão, garantindo que recebe tubos rectos prontos para uma montagem sem problemas.

SOLUÇÕES DE EXTRUSÃO

Endereço de correio eletrónico

sales@jfextruder.com

Endereço da fábrica

No. 31 Yuci Rd., Yuyao, cidade de Ningbo, província de Zhejiang, China