Plastic extruder machines are the backbone of modern manufacturing, shaping everything from pipes to packaging. The choice and configuration of your extruder machine directly determine efficiency, product quality, and long-term profitability. This guide presents a comprehensive overview of extruder machine types, critical components, selection strategies, and best practices, with insights from Jinxin’s decade of experience in precision extrusion equipment.

Plastic Extruder Machine Overview

A plastic extruder machine is engineered to convert raw plastic material—typically pellets or powder—into continuous profiles with a consistent cross-section. The process involves controlled melting, mixing, shaping, and cooling. Key elements include a feed system, screw and barrel assembly, temperature control, die, and downstream equipment. Jinxin specializes in single-screw extruders and dedicated lines for pipes, hoses, and specialty profiles, focusing on dimensional accuracy and process stability.

Types of Plastic Extruder Machines

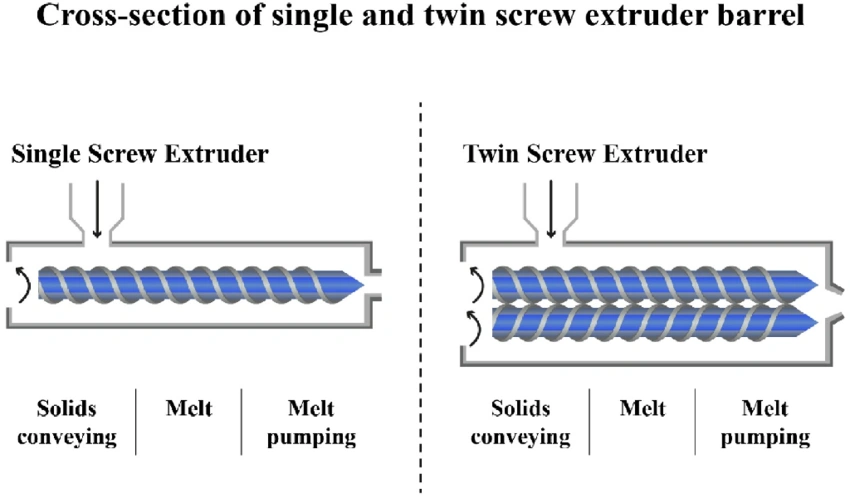

Plastic extruders are classified by screw configuration and application. The main types are single-screw, twin-screw, and specialized extruders.

Single-Screw Extruders

Single-screw extruders dominate the market for standard thermoplastics and high-throughput applications. They offer a straightforward design, reliable operation, and cost-effective maintenance. Jinxin’s single-screw extruders are optimized for PP/PE pipe production and PVC braided hose lines, delivering stable output and precise control.

Twin-Screw Extruders

Twin-screw extruders, available in co-rotating and counter-rotating designs, provide enhanced mixing and compounding capabilities. They are preferred for complex formulations, filled or blended materials, and applications requiring intensive dispersion. While Jinxin’s core expertise is single-screw technology, we offer guidance for customers evaluating twin-screw solutions.

Specialized Extruders

Certain applications demand custom extruder designs, such as multi-layer co-extruders, micro-extruders for laboratory use, and machines tailored for TPE elastic bands. Jinxin develops purpose-built solutions for unique product requirements.

For a detailed comparison, see Single vs. Twin-Screw Guide.

Key Components of a Plastic Extruder Machine

Performance and reliability depend on the quality and integration of each component.

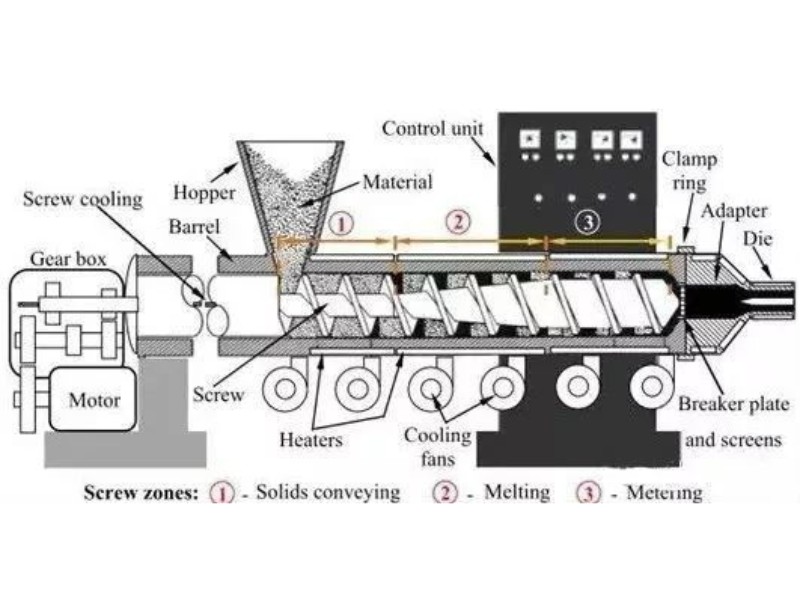

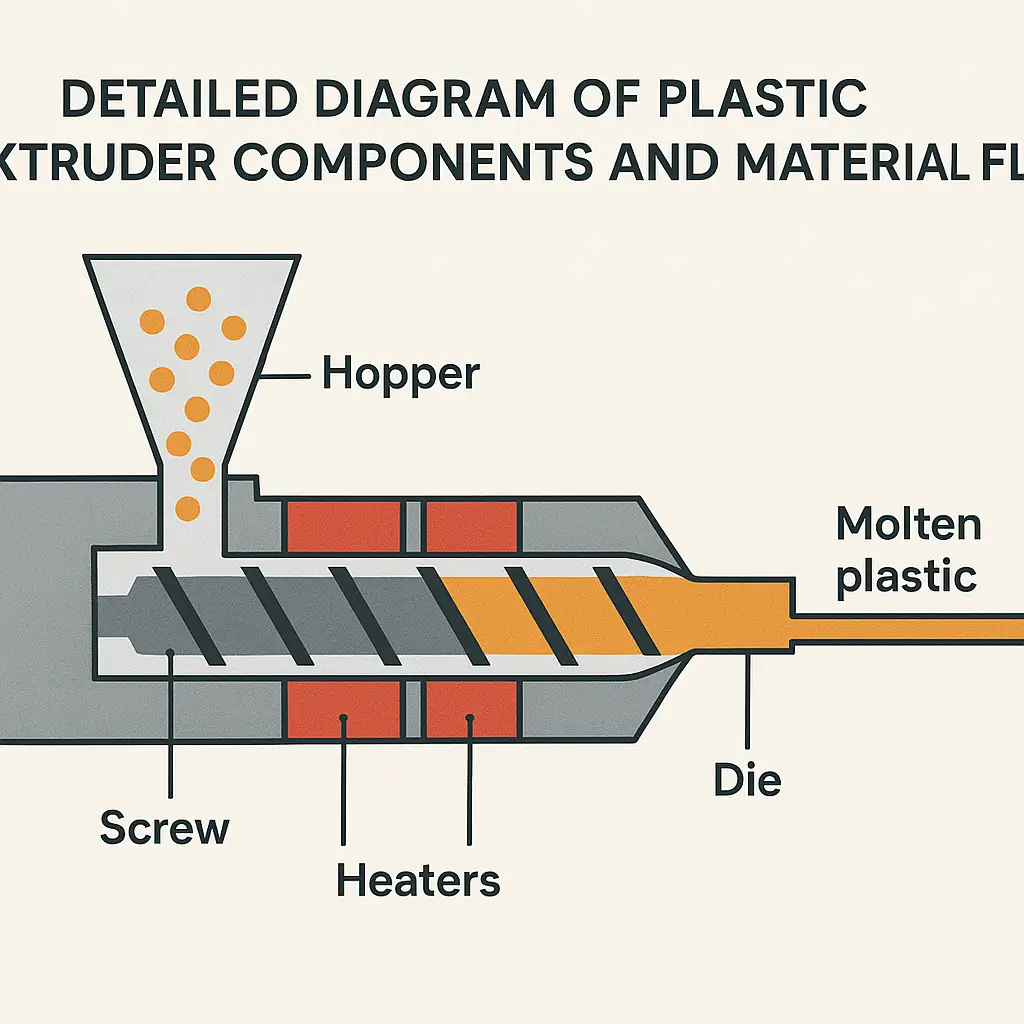

Feed System

The feed system includes a hopper, feed throat, and optional gravimetric dosing. Consistent, contamination-free feeding is essential for stable output.

Screw and Barrel

The screw’s geometry (length, diameter, compression ratio, mixing zones) determines melting efficiency and throughput. The barrel, usually made from hardened steel, must maintain precise temperature profiles. Jinxin’s screws are engineered for optimal melting and minimal wear.

Heating and Cooling

Multi-zone electric heaters and water or air cooling channels maintain stable processing temperatures. PID temperature control systems, as used by Jinxin, ensure deviations stay within ±0.5°C.

Die System

The die shapes the molten plastic into its final cross-section. Custom die design is critical for product accuracy and surface quality.

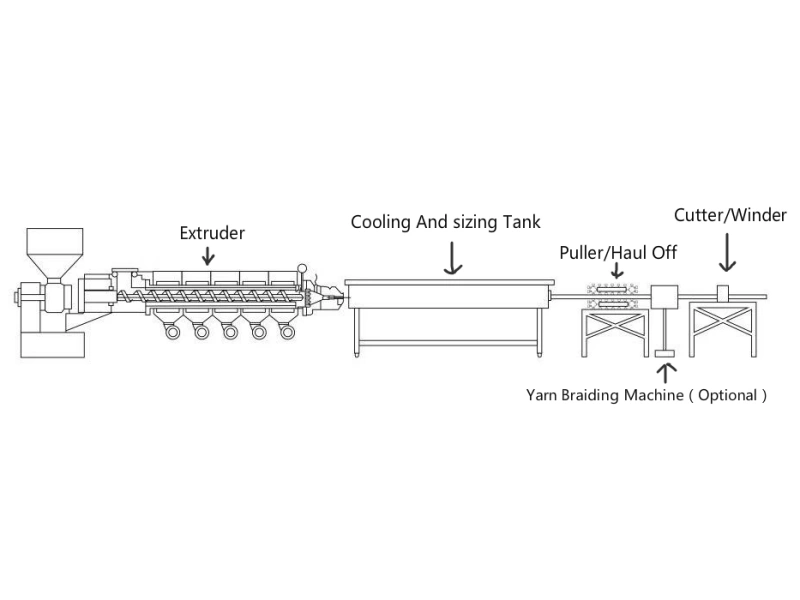

Downstream Equipment

This includes calibration, cooling tanks, haul-off units, cutters, and winders. Each stage must be synchronized for consistent product dimensions.

For more on component functions, see Plastics Technology’s Extruder Hardware Guide.

The extrusion process follows a linear sequence:

- Raw material enters the hopper.

- The rotating screw conveys and melts the material inside the heated barrel.

- The molten polymer is pressurized and filtered before entering the die.

- The shaped extrudate is cooled and solidified.

- The product is pulled, cut, or wound as required.

Process stability depends on precise temperature, pressure, and speed control at every stage. Jinxin’s systems employ advanced PID control and real-time monitoring for consistent results.

Applications of Plastic Extruder Machines

Extruder machines are integral to the production of:

- Water and gas pipes (PP, PE, PVC)

- Reinforced hoses for garden, washing machine, and industrial use

- Multi-color shower hoses

- LED lighting profiles (PC, PMMA)

- TPE elastic bands for medical and sports applications

Jinxin’s portfolio includes TPE Elastic Band Extruders and other specialized lines tailored for these industries.

How to Select the Right Plastic Extruder Machine

Selection should be based on:

- Product type and dimensions

- Material compatibility

- Output requirements

- Precision and quality standards

- Budget and available space

- After-sales and technical support

Jinxin offers application-specific recommendations and custom engineering for unique requirements. For pipe production, see our PP/PE Pipe Extruder.

Maintenance and Operation of Plastic Extruder Machines

Routine maintenance is essential for long-term reliability:

- Regular inspection and cleaning of screw, barrel, and die

- Monitoring of temperature and pressure sensors

- Lubrication and alignment of mechanical parts

- Scheduled replacement of wear components

Jinxin provides comprehensive maintenance manuals and technical support. For best practices, refer to Davis-Standard’s Quarterly Extruder Performance Checklist, which offers a detailed maintenance program covering control panels, feedscrews, barrels, and other critical components

Future Trends in Plastic Extruder Machines

The future of plastic extruder machines is exciting. We’re seeing trends like:

- Automation: Smart controls for precision.

- Durabilité: Machines designed for recycled plastics.

- Efficacité énergétique: Lower costs and environmental impact.

At Jinxin, we’re leading the way in innovating plastic extruder machine technology.

Conclusion

Plastic extruder machines are essential for modern production, and we at Jinxin are proud to provide top-tier solutions. Whether you’re exploring types, components, or applications, this guide has you covered. Ready to take the next step? Visit jfextruder.com to find the perfect plastic extruder machine for your needs!